A construction method of a prestressing device for bridges without prestressing beams

A technology for applying devices and construction methods, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of low construction safety, long construction period, high construction cost, and achieve good safety controllability, short construction period, environmental protection low pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

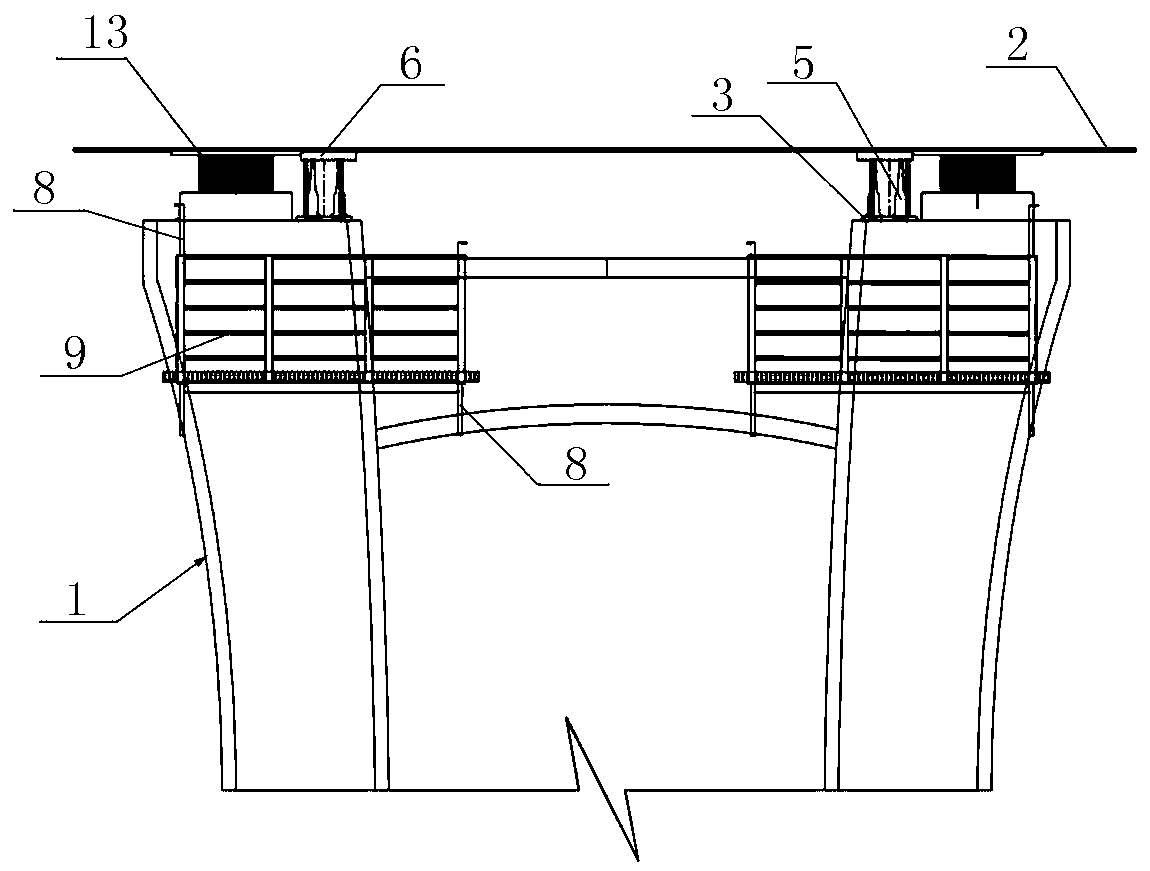

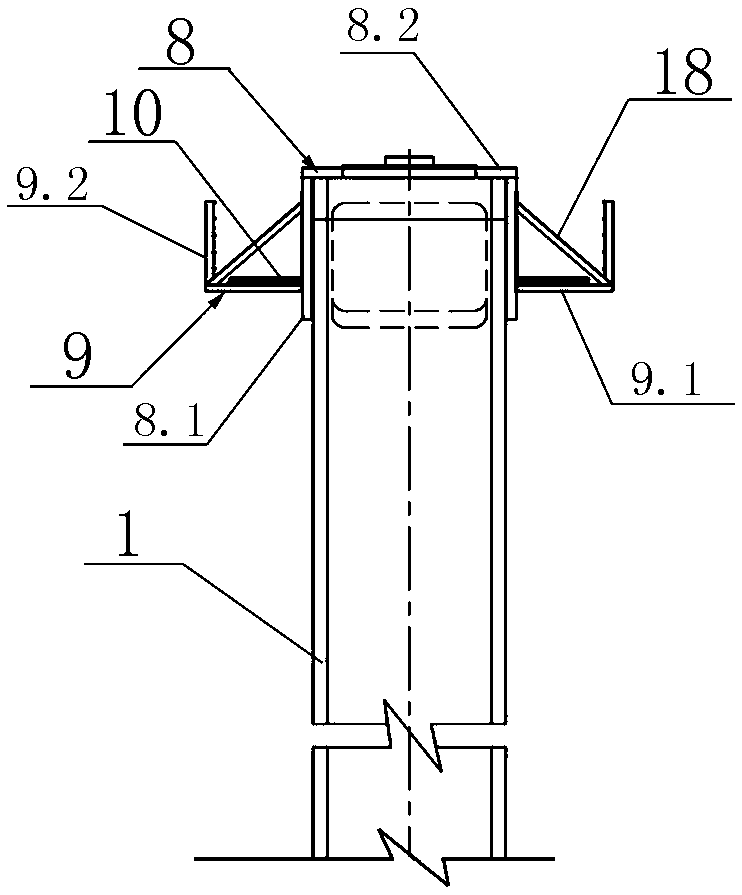

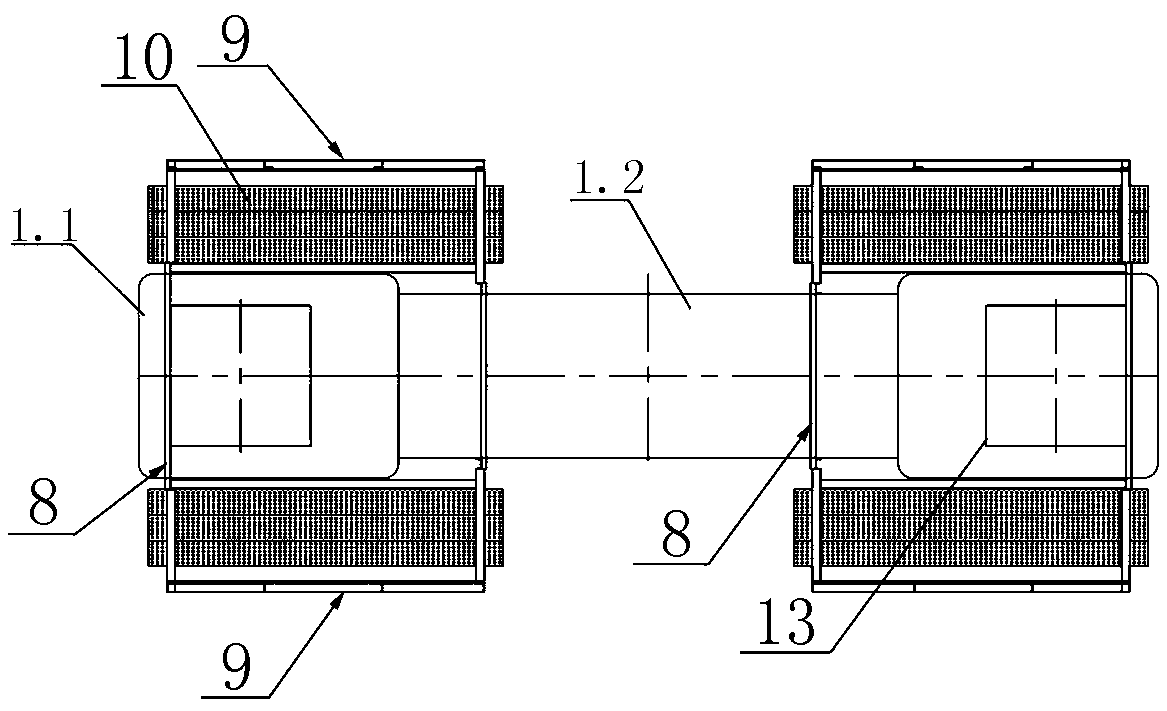

[0047] This prestress applying device for bridges without prestressed beams is arranged between the top of the pier 1 and the bottom of the steel box girder 2, and is located inside the support 13 of the pier 1 and the steel box girder 2; it includes a backing plate 3, a synchronous Hydraulic jack 4, screw jack 5, and leveling plate 6; the backing plate 3 is longitudinally arranged on the top of the pier 1, close to the position of the support 13; Each group of screw jacks 5 is arranged at intervals along the horizontal direction; the synchronous hydraulic jacks 4 have one group, and are arranged between two groups of screw jacks 5 at intervals along the longitudinal direction; Between the top of the screw jack 5 and the steel box girder 2, and the top slope of the leveling plate 6 is compatible with the slope of the bottom longitudinal slope of the steel box girder 2.

[0048] In this embodiment, the length of the backing plate 3 is not less than 160 cm, and the width of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com