Integral framework type building steel structure and assembling method

A technology of integral frame and steel structure, which is applied in the direction of building structure and construction, can solve the problems of time-consuming and laborious installation and disassembly, low stability, inconvenient transportation, etc., and achieve the effect of reducing assembly time, high assembly efficiency, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

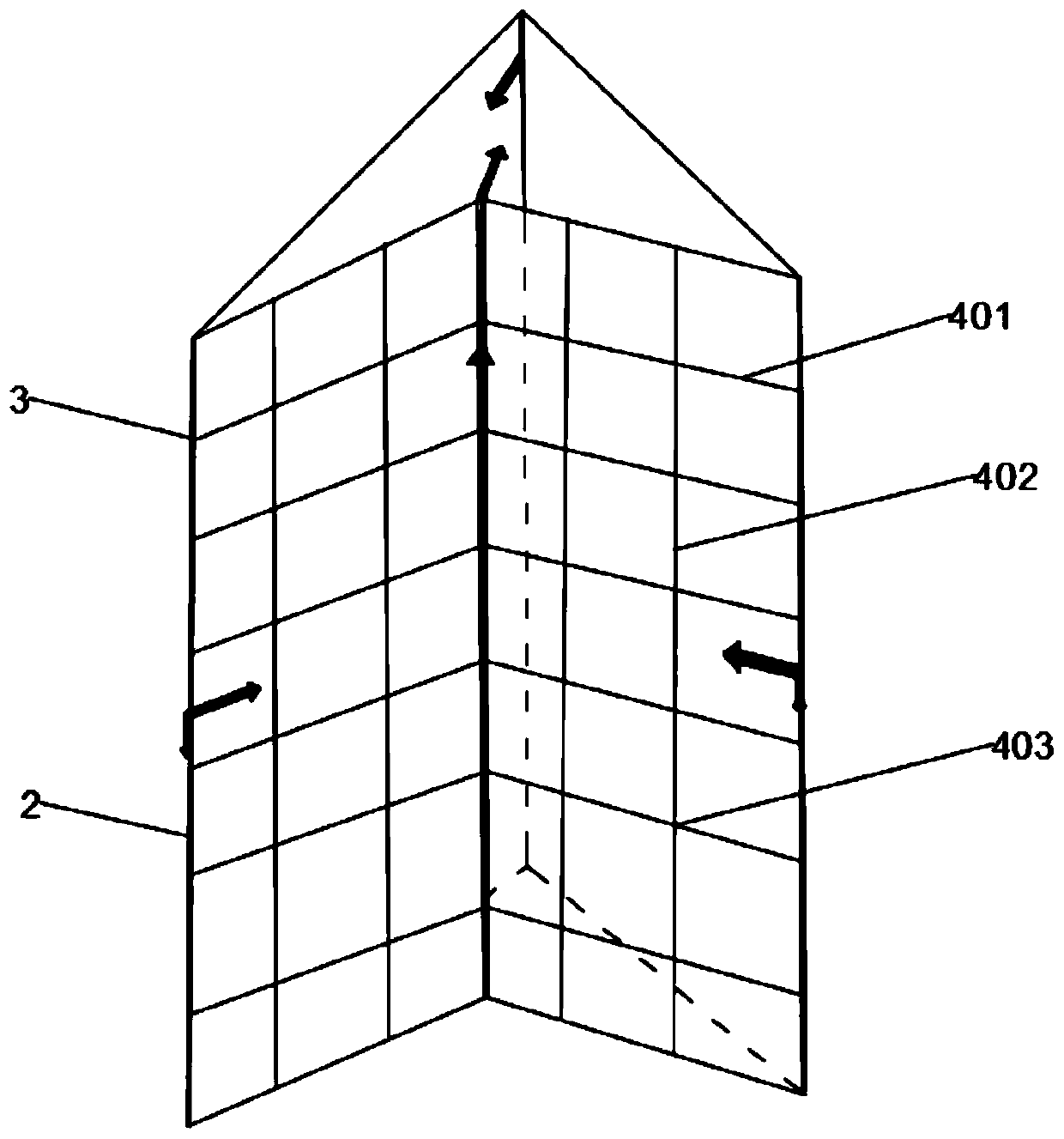

[0051] For this, as Figure 1 to Figure 10 As shown, the present invention provides an integral frame-type building steel structure, which aims to pre-integrate the steel structure of the frame-type building into a whole that can be contracted and expanded. When in use, just unfold it directly. There is no need to install too many components, which greatly reduces the construction time of the frame building and improves the construction efficiency. specific:

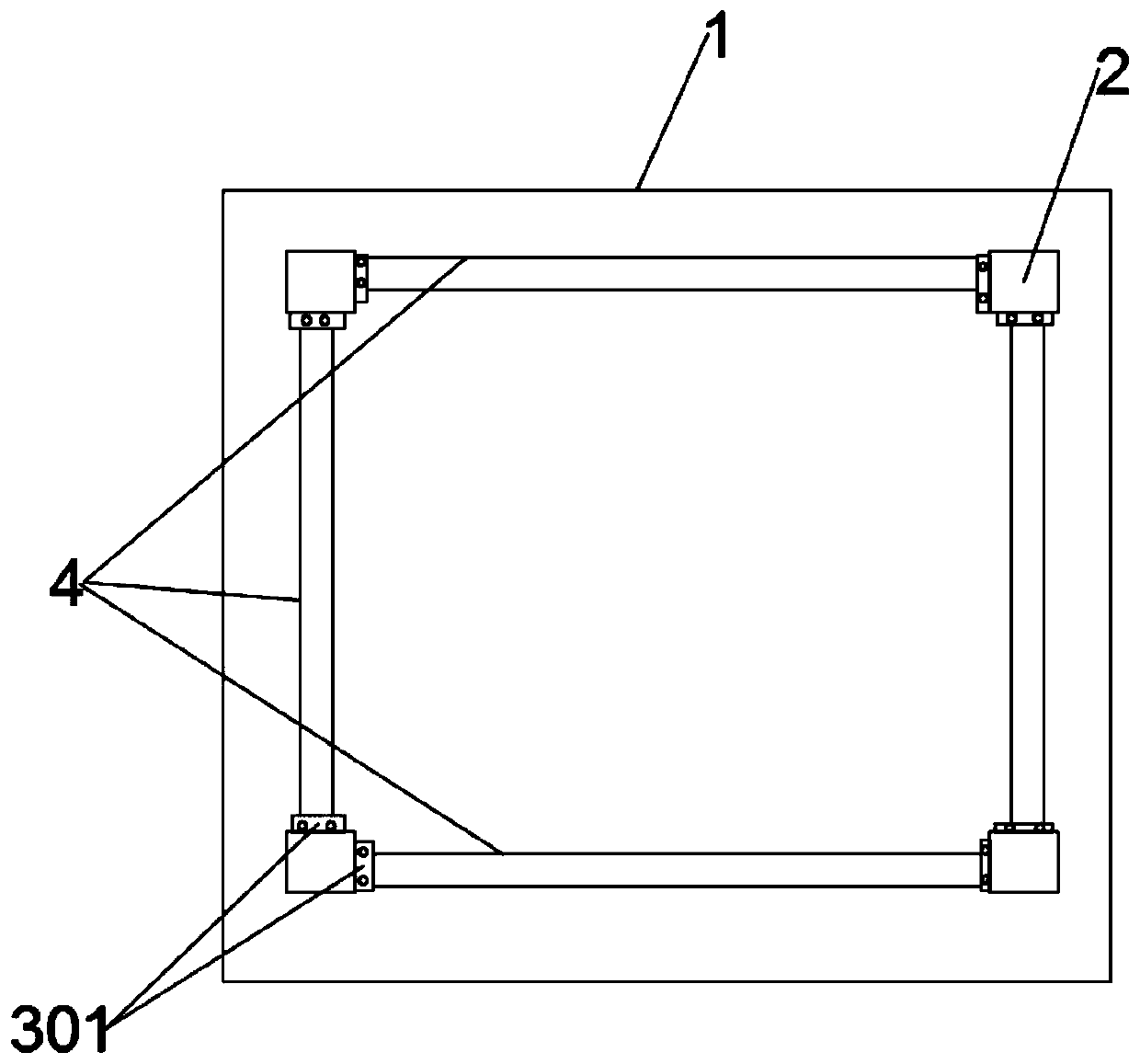

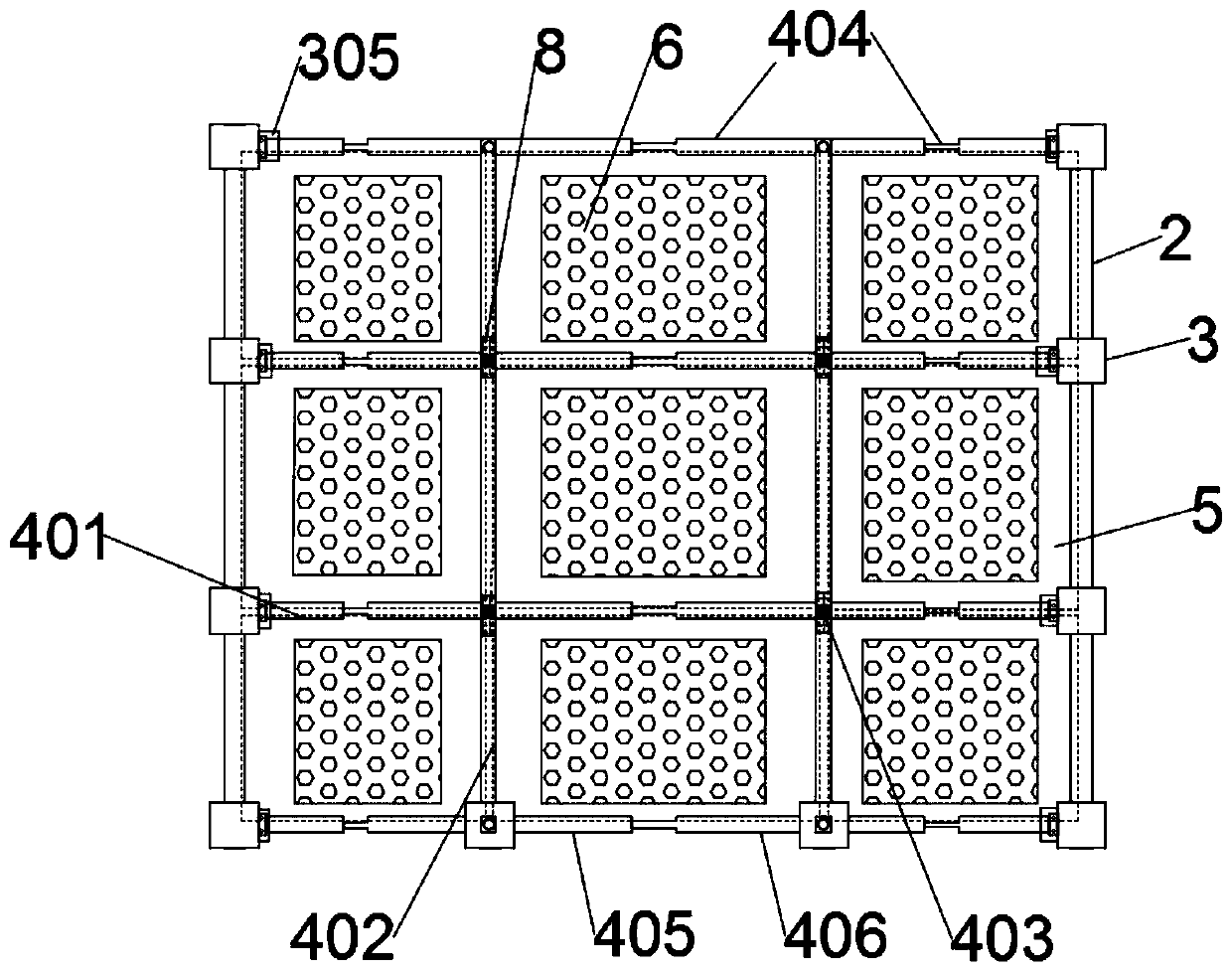

[0052] The building steel structure includes a plurality of corner prefabricated steel columns 2 vertically connected to the bottom plate 1 , and a plurality of hinge joints 3 are arranged on the corner prefabricated steel columns 2 . A plurality of hinge joints 3 are distributed at intervals along the height direction of the corner prefabricated steel columns 2, and a foldable wall support assembly 4 is movably connected between two adjacent corner prefabricated steel columns 2 through the hinge joints 3 arranged faci...

Embodiment approach

[0069] As a preferred embodiment: the vertical limit assembly 8 includes a limit slider 801 that is arranged on the vertical steel column 402 and can slide along the length direction of the vertical steel column 402, and the limit slider 801 is provided with a limit guide groove 802 , the assembling cross bar 407 is provided with a limit guide strip 803 perpendicular to the extending direction of the assembling cross bar 407 , and the limit guide bar 803 can be set inside the limit guide groove 802 .

[0070] After the horizontal steel column assembly 401 and the vertical steel column 402 are adjusted to be perpendicular to each other, the limit guide groove 802 on the limit slider 801 and the limit guide bar 803 are located on the same straight line. Push the limit slider 801, engage the limit guide bar 803 inside the limit guide groove 802, and the vertical relationship between the horizontal steel column assembly 401 and the vertical steel column 402 will be locked.

[0071...

Embodiment 2

[0075] Such as Figure 11 As shown, an assembly method of an integral framed building steel structure includes the following steps:

[0076] S100. Unfolding the overall frame: vertically stretch the prefabricated steel columns at the corners of the prefabricated building as the external frame at the turning point, and then unfold the wall support between the prefabricated steel columns at the corners as the internal frame components to complete the preliminary development of the overall frame of the prefabricated building;

[0077] Preferably, the wall support assembly can be folded, and the wall support assembly can pivot at any angle along the connection between the corner prefabricated steel column and the wall support assembly.

[0078]S200. Fixing the internal frame: adjusting the verticality between the mutually hinged vertical and horizontal bars that form the wall support assembly;

[0079] S300. External frame fixation: adjust the two ends of several cross bars that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com