Detector for vacuum state in ship tail shaft sealing chamber

A detector and stern shaft technology, applied in the direction of using liquid/vacuum to measure liquid tightness, and detecting the appearance of fluid at the leakage point, etc., can solve the problems of unqualified stern shaft seal, reduced inspection efficiency, and cumbersome procedures , to achieve the effects of easy disassembly and assembly detection, high detection efficiency and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be further described below in conjunction with the drawings and embodiments. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

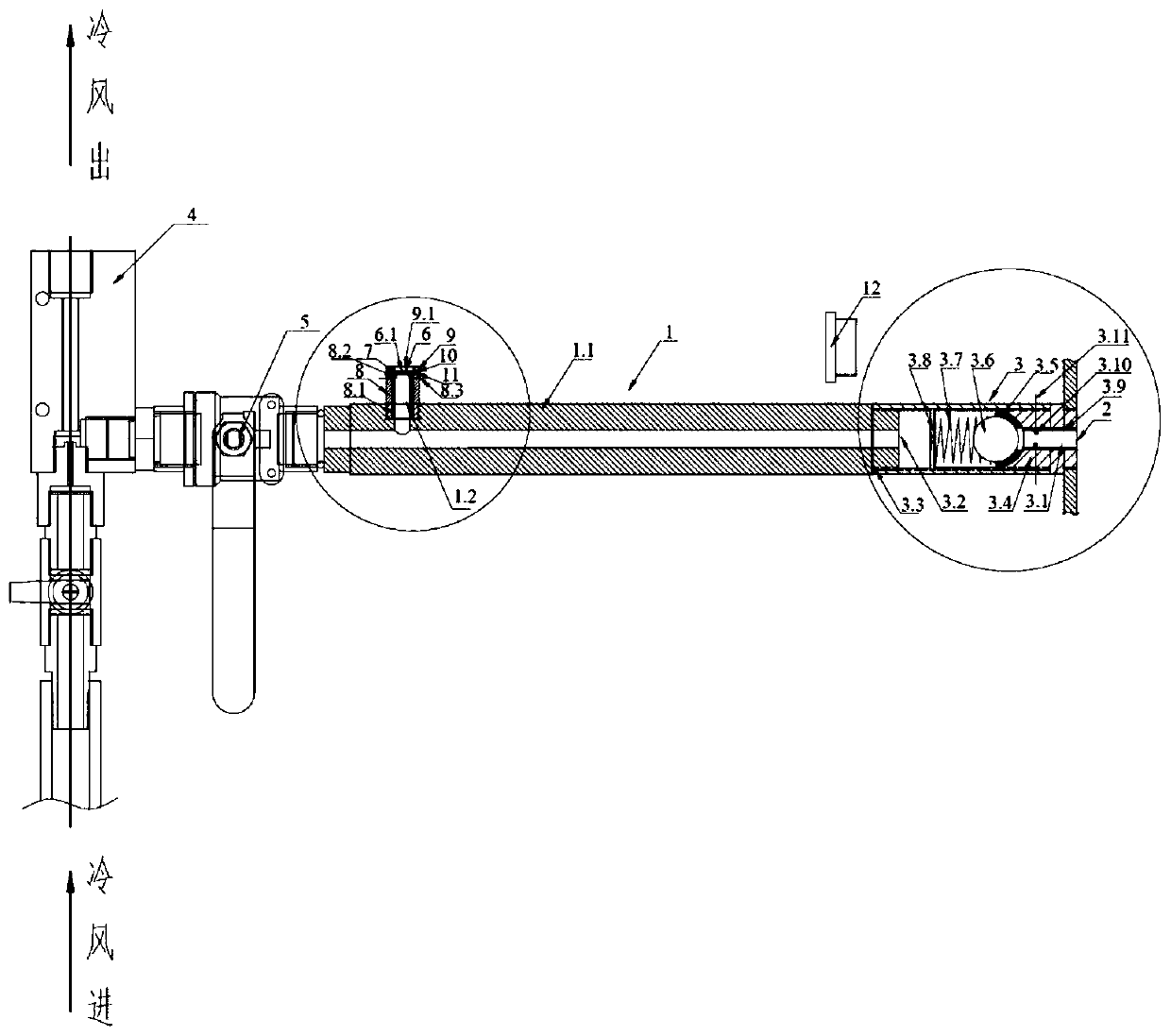

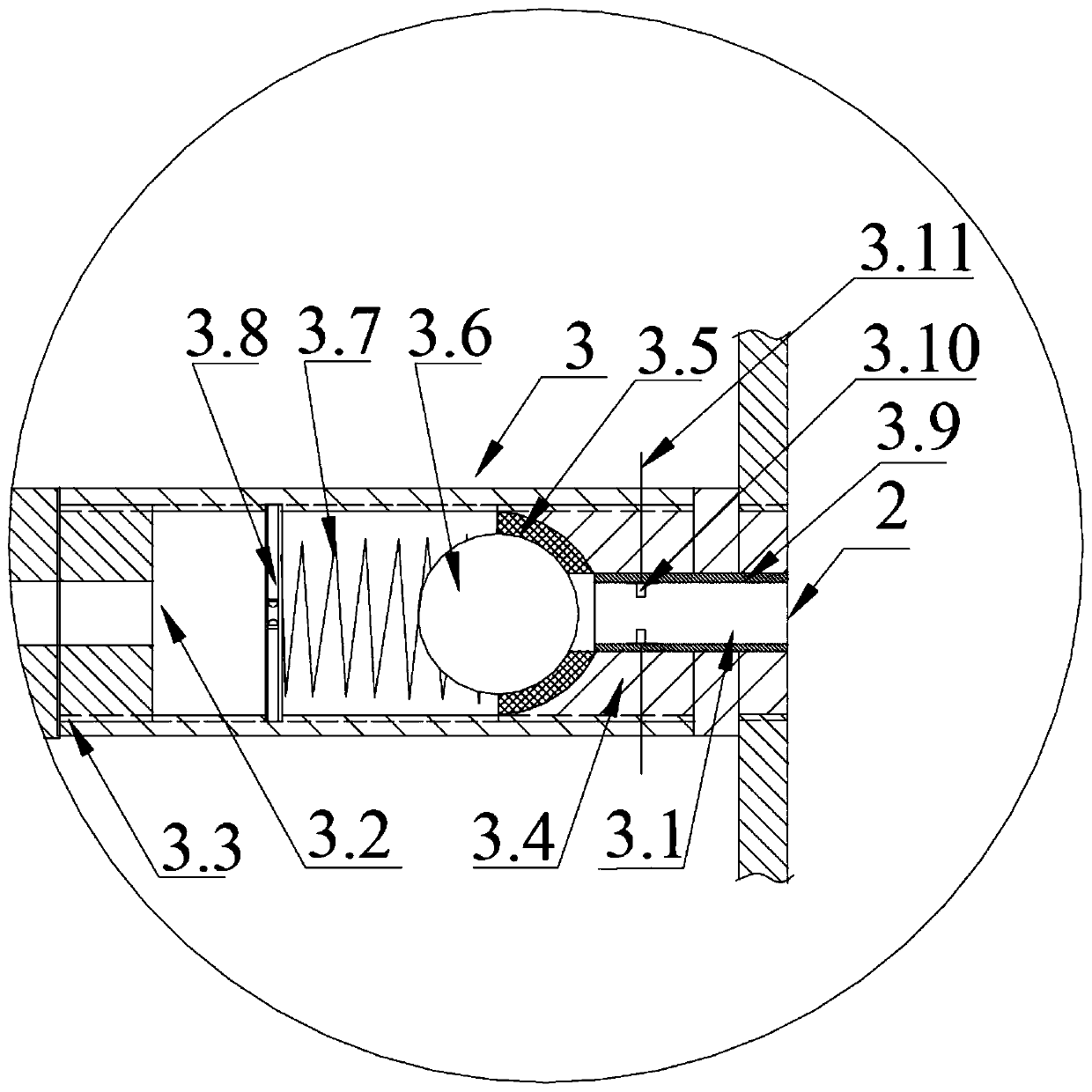

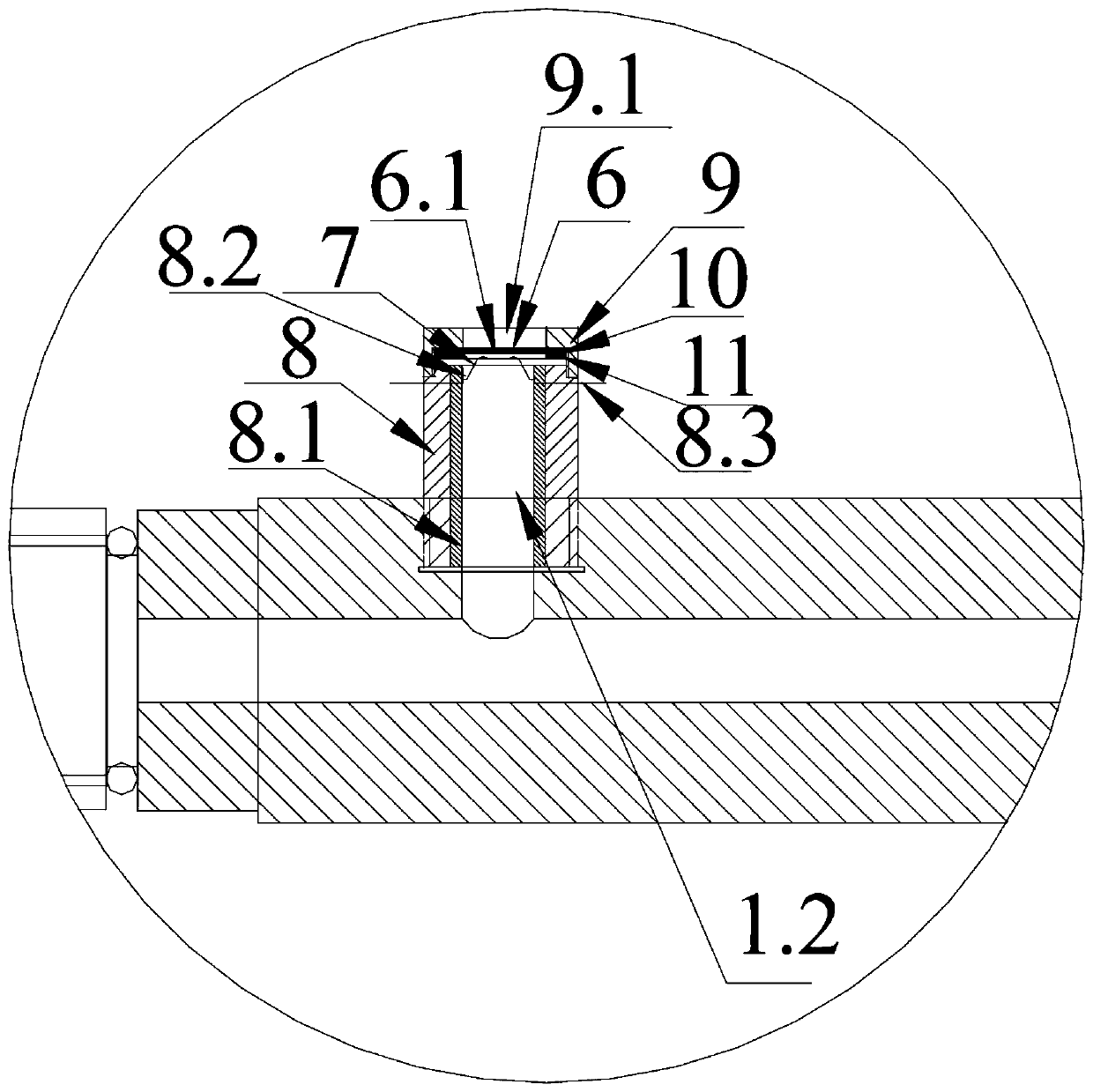

[0022] Such as Figure 1~3 As shown, the present invention is a vacuum state detector in a sealed chamber of the stern shaft of a ship. A plurality of sealed chambers are arranged on the stern shaft of the ship. The detector 1 includes a detector 1 arranged on the side wall of each sealed chamber. The detection port 2 is used to detect the internal sealing state of the chamber, and the detection port 2 of each sealed chamber is connected to the inlet port 3.1 of the one-way valve 3, or multiple detection ports 2 are connected in series After that, it is connected with the inlet port 3.1 of the one-way valve 3 through a connector. The other end of the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com