Acoustic test platform capable of characterizing metal meso-damage change and test method

An acoustic testing and mesoscopic technique, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, scientific instruments, etc. It can solve the problems of insufficient damage to mechanical equipment and damage to metal materials, and achieve the effect of easy observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention will be further described:

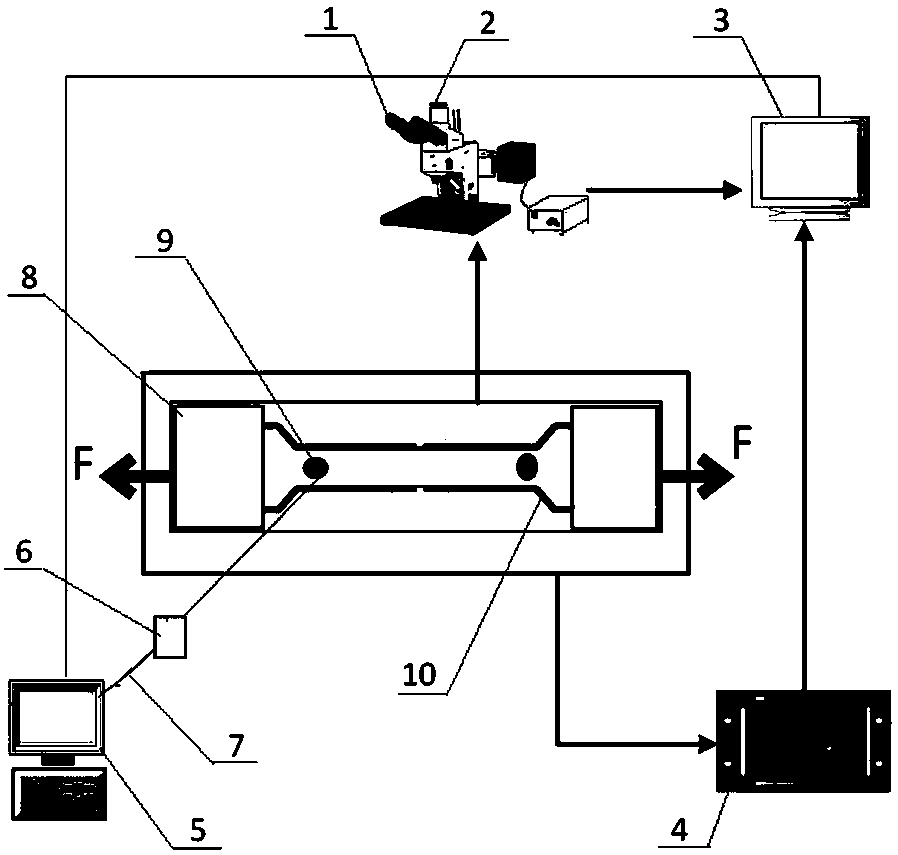

[0018] Such as figure 1 As shown, this acoustic testing platform that can characterize metal mesoscopic damage changes includes a micro-force in-situ tensile test loading mechanism, a mesoscopic damage observation mechanism, and a weak acoustic signal detection mechanism. The micro-force in-situ stretching machine 8 is set on the stretching test platform, and the micro-force in-situ stretching machine 8 is connected to the acoustic signal data acquisition system 4 to form; the acoustic signal data acquisition system 4 is connected to the computer 3, and the acoustic signal data acquisition system 4 is the PAC acoustic signal data Acquisition system, computer 3 with AEwin software, micro force in-situ stretching machine 8 and acoustic signal data acquisition system 4, its function is to stretch the test specimen at a certain rate and record real-time stretch data.

[0019]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com