Multi-axis linkage exposure device and exposure method for product with arc transition angle

A multi-axis linkage and exposure device technology, which is applied in the field of exposure machines, can solve the problems of inability to expose at arc transition angles and low efficiency, and achieve the effects of constant exposure focal length, high exposure efficiency, and reliable action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

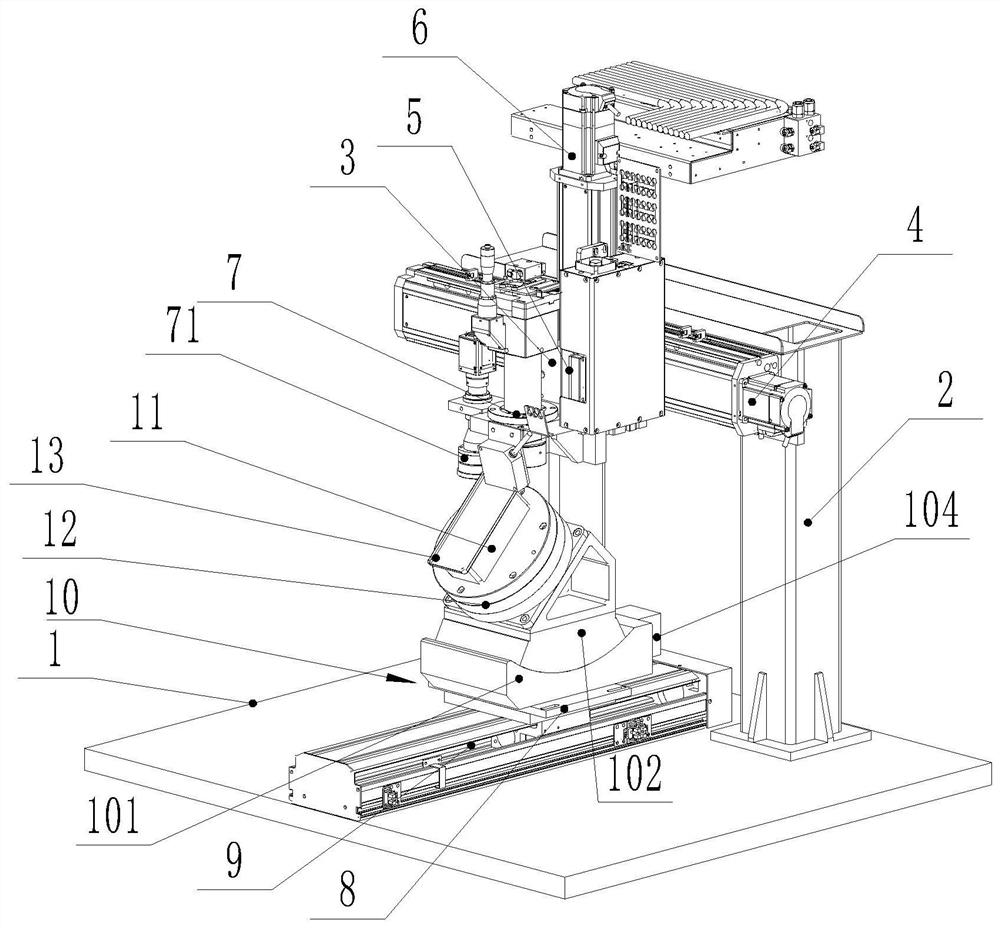

[0043] Such as Figure 1 to 2 As shown, the present invention provides a multi-axis linkage exposure device with an arc surface transition angle product 13, including a seat 1, and an exposure frame 2 is provided on the base 1, in the present embodiment, the exposure rack. 2 With the structural form of the gantry, the exposure frame 2 is slidably mounted in the x-direction 3, and the X slide 3 is driven by the X power device 4, and the X-slide 3 slides vertically and mounted. The slide 5 is driven by the Z power device 6, and the Z-slide 5 is mounted on the Y direction 8, which slides in the Y direction on the Y direction 8, the Y slide The seat 8 is driven between the upper position and the exposure station, which is mounted on a deflection device 10 deflecting a central axis parallel to the X direction. There is a product fixing plate 11 driven by the product rotation power device 12, the rotation centerline of the product fixing plate 11 is located in the YZ plane. The rotating ...

Embodiment 2

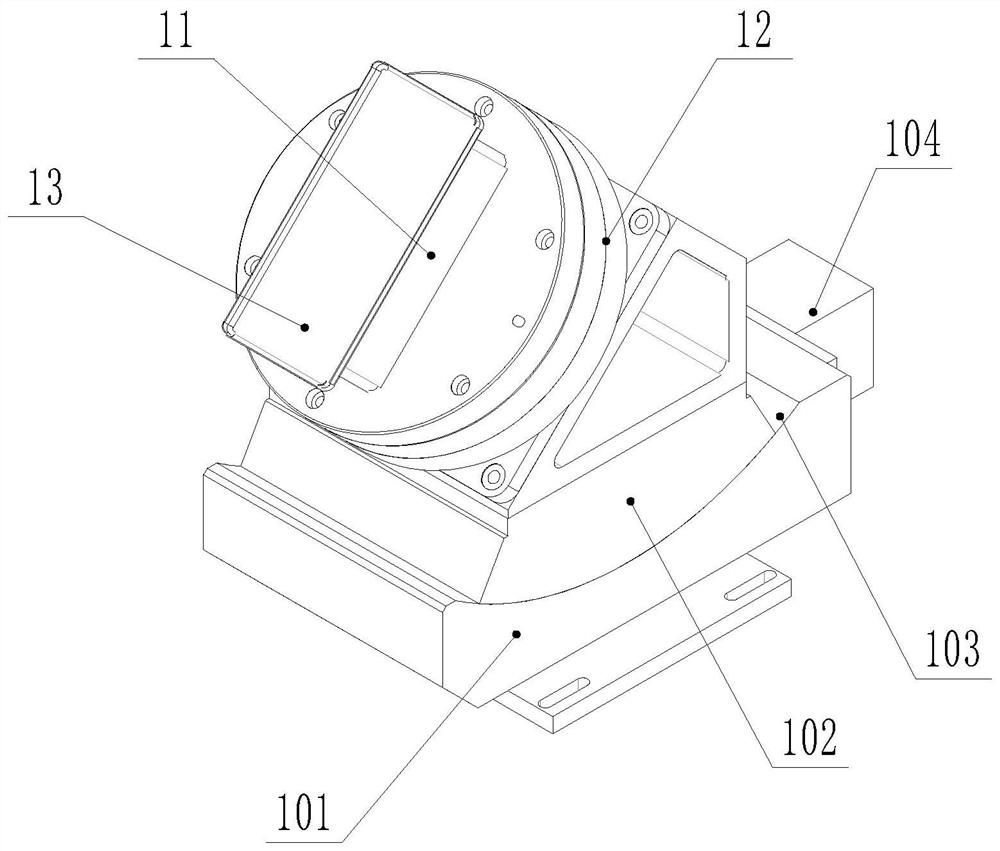

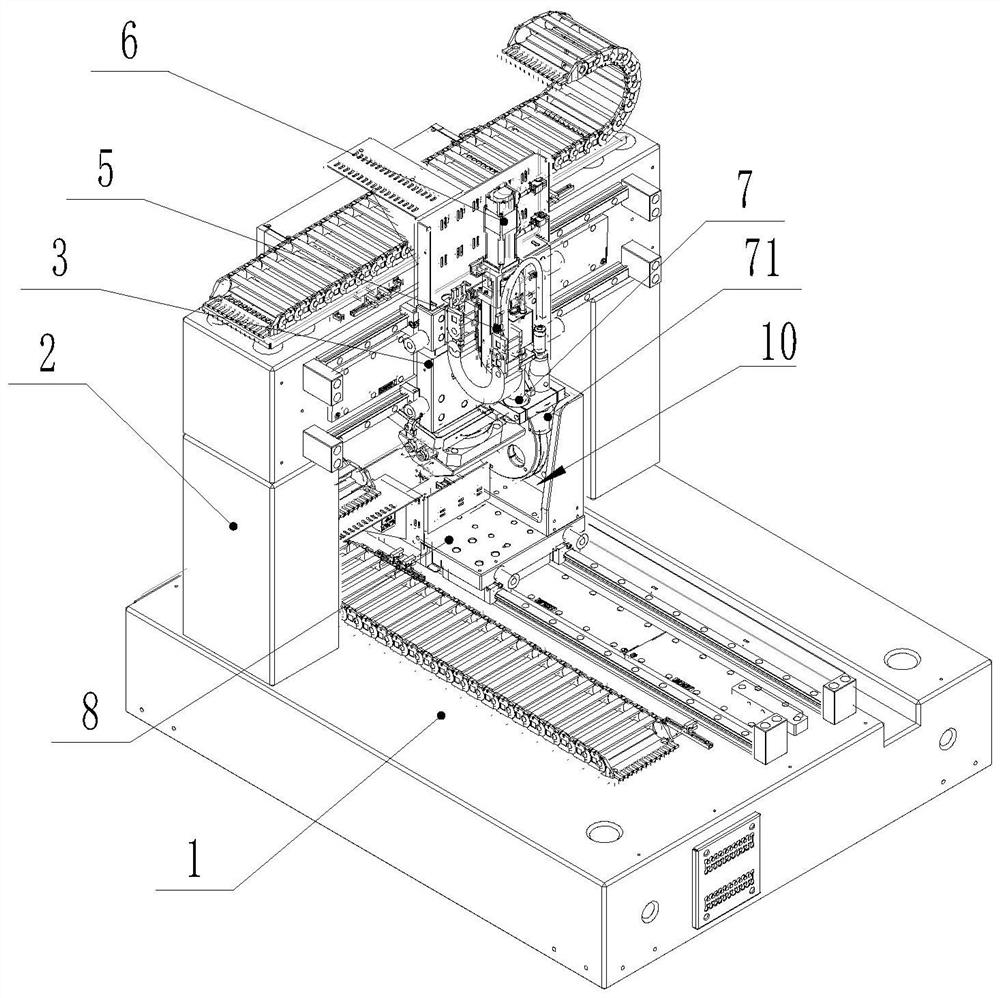

[0051] The structure of the present embodiment and the structure of Example 1 are basically the same, such as Figure 3 to 6 As shown, the X power device 4, the Y power device 9 and the Z power device 6 are driven by a linear motor, and therefore, both the X Slide 3, the Y Side 8, and the Z Side 5 are slidable through a linear guide, and the implementation In the case, the deflection device 10 is in another configuration, and the deflection angle of the deflection device 10 in the first embodiment is relatively small, and in the present embodiment, the deflection device 10 includes a deflection base 101 fixed to the Y footage 8. The deflection base 101 is rotated to be mounted, in the present embodiment, the deflection seat 102 is a plate-like structure, which is driven by the deflection power device 104, the product rotation power device 12 and the product fixation The plate 11 is mounted on the deflection seat 102. The same in which the deflection power unit 104 and the product r...

Embodiment 3

[0056] This example discloses a multi-axis linkage exposure method with an arc surface transition angle product 13, which uses the exposure apparatus described above, including the steps of:

[0057] S1, the product 13 to be exposed is placed and fixed to the product fixing plate 11 in the upper station, which is a negative pressure fixed manner, and since the negative pressure is fixed, different sizes can be fixed. Product 13 to be exposed;

[0058] S2, the Y power device drives the Y-slide slide in the Y direction to place the product 13 in the exposure station, in this embodiment, the Y Side 8 is sliding between the upper position and the exposure station, can be worked in the manipulator When the product 13 is placed on the product fixing plate 11, while the product fixing plate 11 is driven by the deflection device 10, so that the product 13 is more accurately placed; the sliding of the slide 8

[0059] S3, during the sliding process of the Y foot 8 or after the Y football 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com