Coal mine safety risk grading management and control method

A technology for coal mine safety and risk classification, applied in database management systems, structured data retrieval, resources, etc., can solve problems such as inability to fully grasp, frequent safety accidents, and heavy casualties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

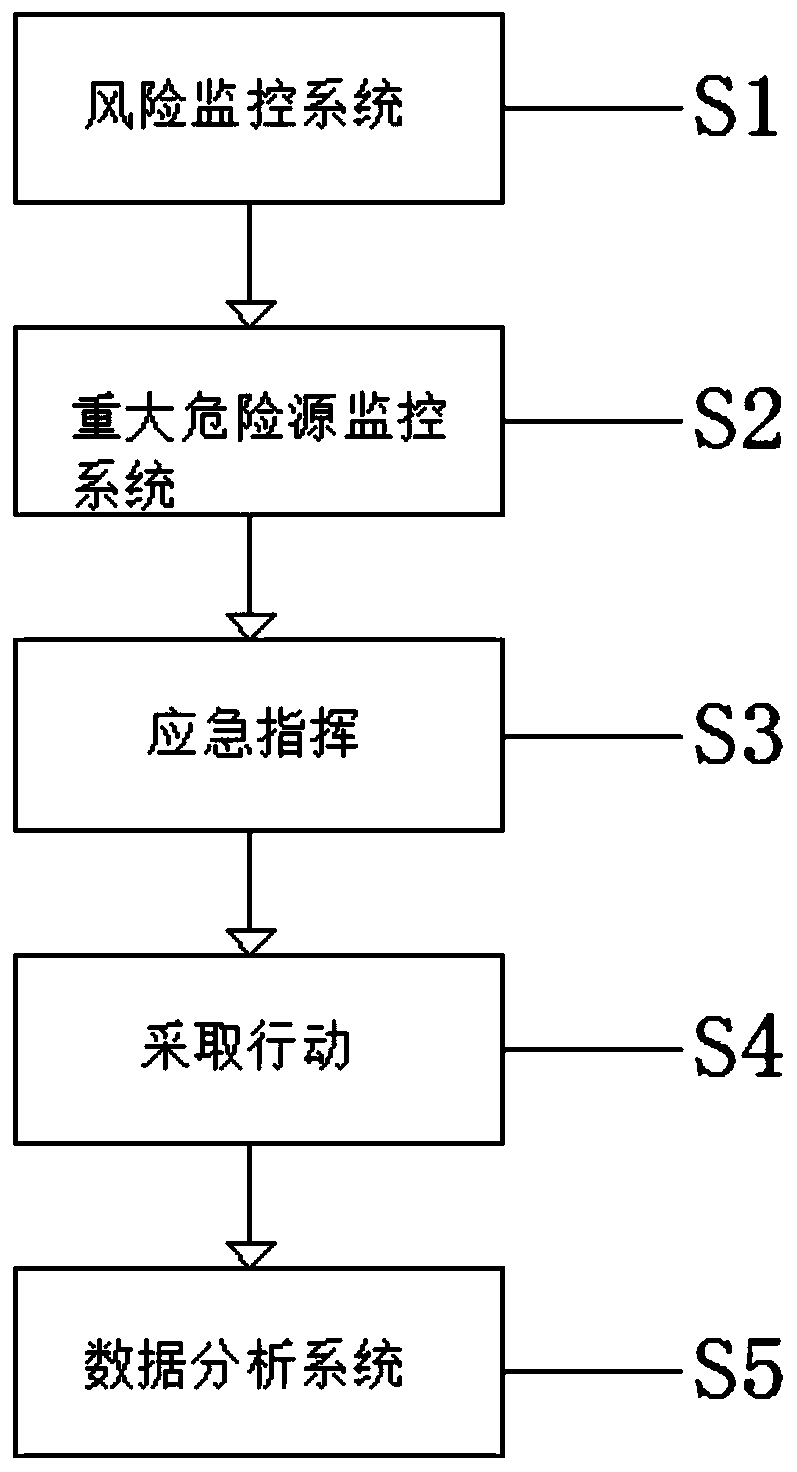

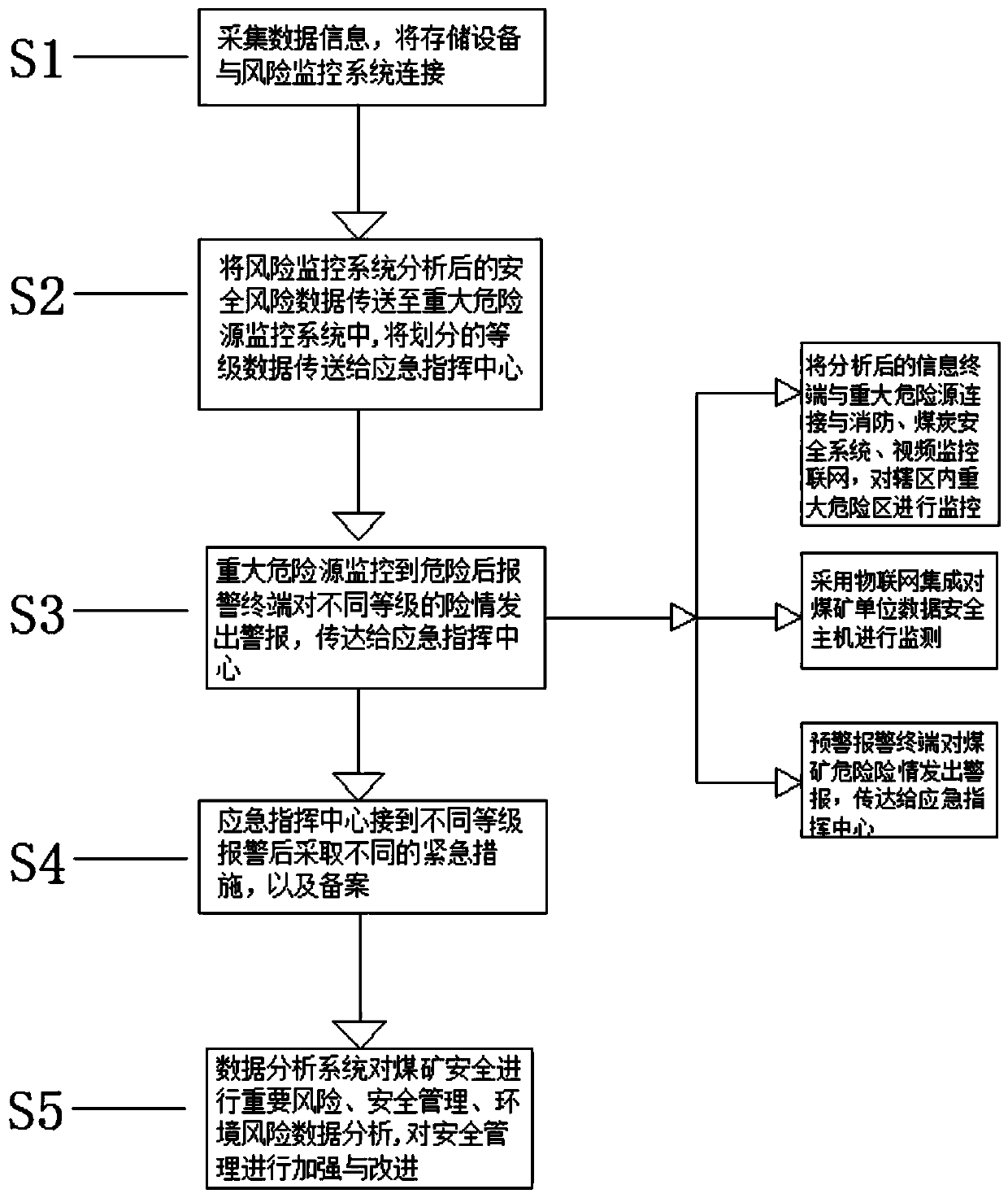

[0023] Such as Figure 1-2 As shown, a coal mine safety risk classification management and control method adopts the following steps:

[0024] Step S1: collect data information, connect the storage device with the risk monitoring system, evaluate and analyze the coal mine risk through the risk monitoring system, obtain safety risk data, and store the safety risk data in the storage device;

[0025] Step S2: Transmit the safety risk data analyzed by the risk monitoring system to the major hazard source monitoring system, identify and evaluate the major risks in potential safety hazards, divide the risk levels, and transmit the divided level data to the emergency command center ;

[0026] Step S3: Network the major hazard sources with the fire protection system, the coal safety system, and the video surveillance system to monitor the major hazard areas within the jurisdiction, and use the Internet of Things technology to connect the coal mine safety big data in the computer hos...

Embodiment 2

[0031] In the step S5, the data analysis system and the coal mine unit open the data interface, unify the data analysis and supervision platform, improve the information resource sharing ability, ensure the smooth flow of information, establish a scientific and convenient information analysis platform, and improve the rapid response to security emergencies ability.

[0032] The present invention is improved in that: the safety risk data analyzed by the risk monitoring system is transmitted to the major hazard source monitoring system, and the major risk data unified collection interface platform is constructed with the help of Internet of Things technology to realize real-time monitoring of information collection points. Once a safety risk occurs , send an alarm to the emergency command center, and the relevant departments of the emergency command respond quickly, so that the danger is always within the controllable range. The hidden danger investigation system makes a systemat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com