Fin type phase change heat dissipation device

A heat dissipation device, finned technology, applied in the field of finned phase change heat dissipation devices, can solve the problems of secondary heat dissipation of the device, failure to absorb heat from heat source, thermal runaway, etc. The structure is simple, the space utilization rate is high, and the effect of increasing heat conduction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

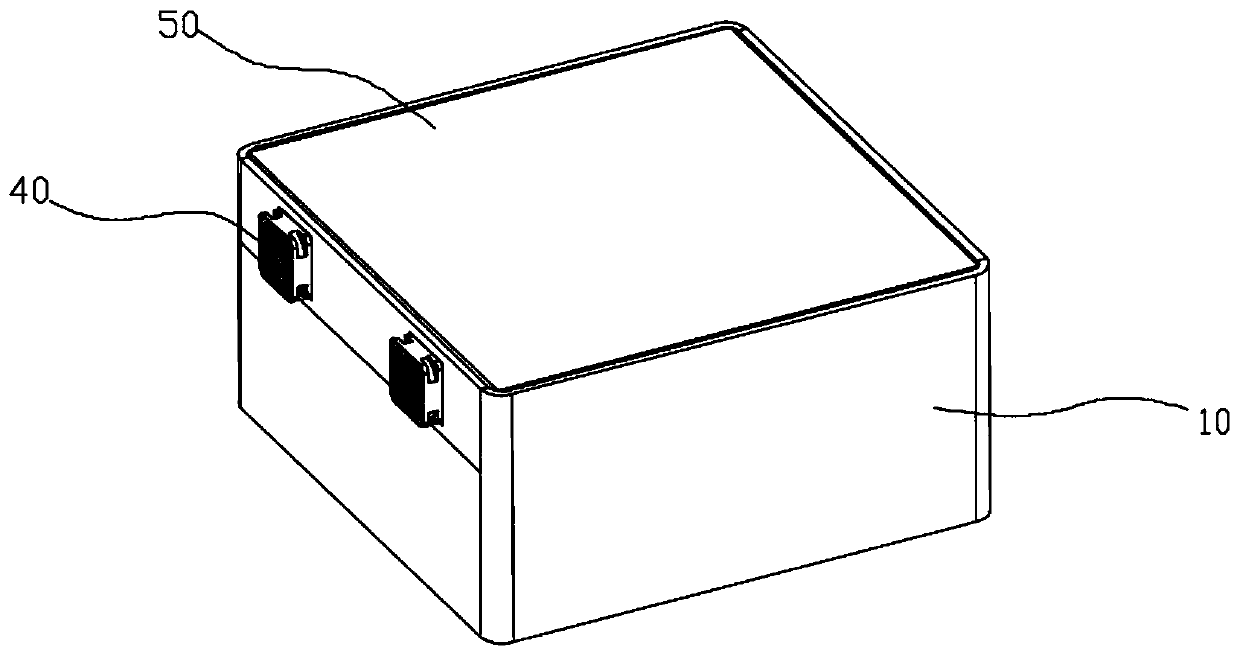

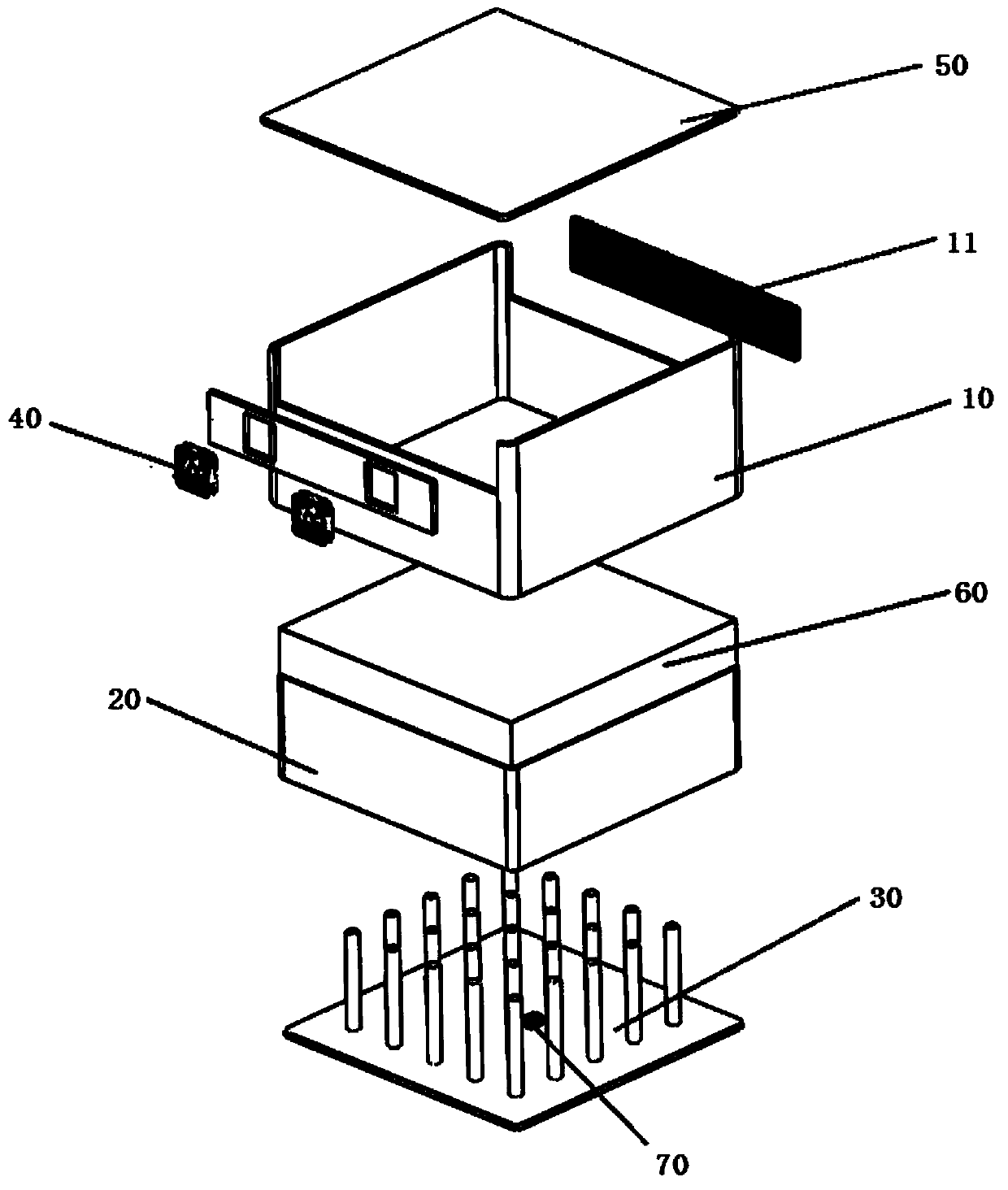

[0025] Please refer to figure 1 with figure 2 , a finned phase change heat dissipation device, comprising a hollow heat dissipation box 10; the heat dissipation box 10 is provided with a metal foam-phase change material composite body 20, and the bottom surface of the metal foam-phase change material composite body 20 is provided with fins Type heat sink 30, the fin of fin type heat sink 30 is inserted in the foam metal-phase change material composite body 10;

[0026] On the side wall of the heat dissipation box 10, an air intake grid 11 is provided above the metal foam-phase change material composite body 20, and an exhaust fan 40 is arranged on the side wall opposite to the air intake grid 11 on the heat dissipation box body 10, and the heat dissipation box body 10 is provided with a top cover 50 .

[0027] As can be seen from the above, when in use, the present invention utilizes the finned heat sink to be in close contact with the heat source to absorb heat, and the ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com