Dry-wet separated vertical lithium battery pack liquid cooling type management system and method

A thermal management system, dry and wet separation technology, applied in the field of vertical lithium battery pack liquid-cooled thermal management system, can solve the problems of large safety hazards, large battery damage, low heat dissipation efficiency, etc., to prevent excessive temperature, solve The effect of high safety hazard and high heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to understand the content of the present invention more clearly, the attached Figure 1-11 Describe in detail with specific embodiments.

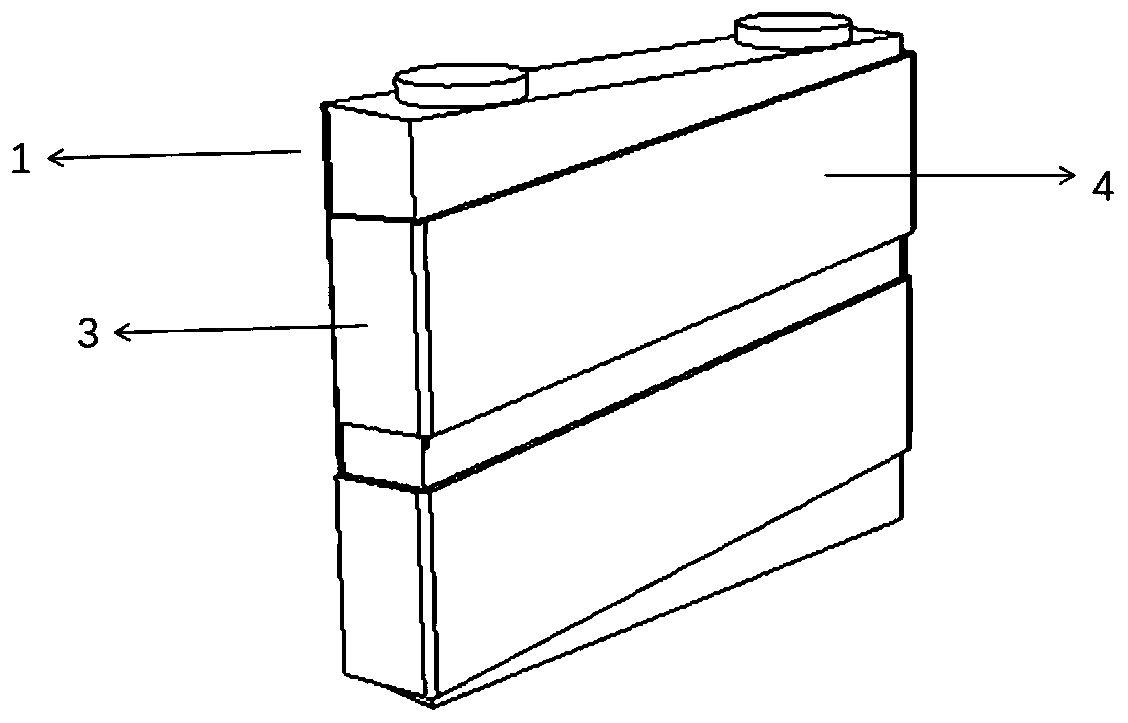

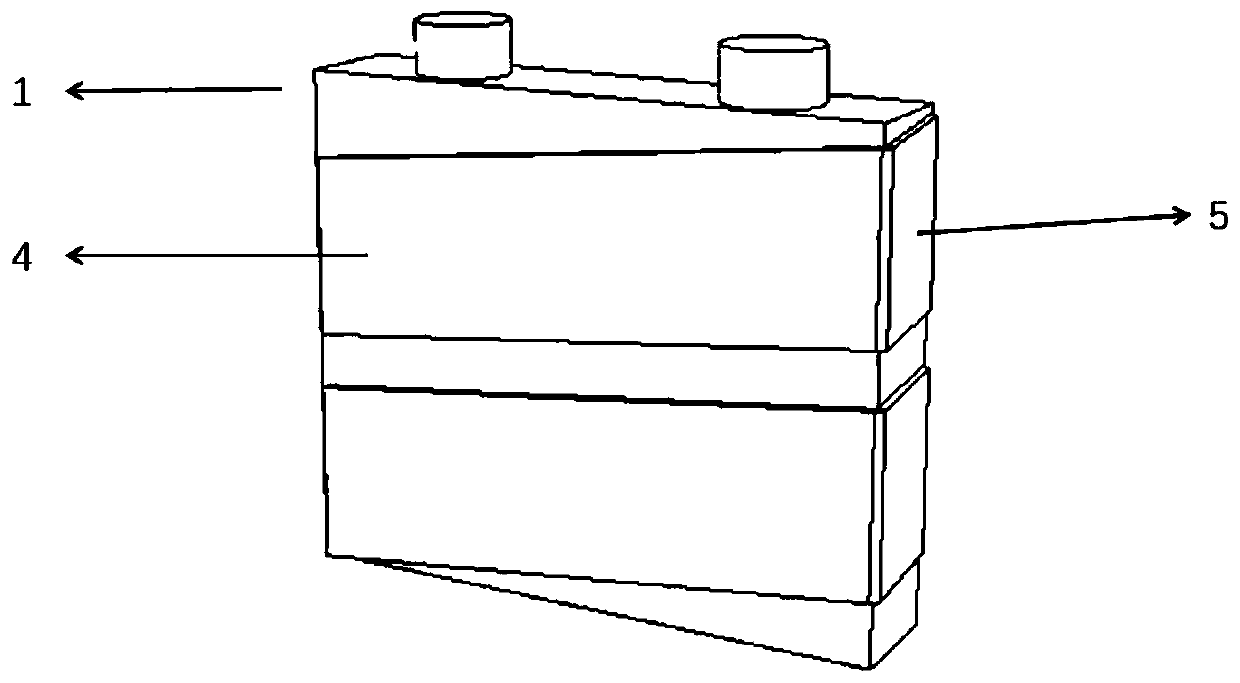

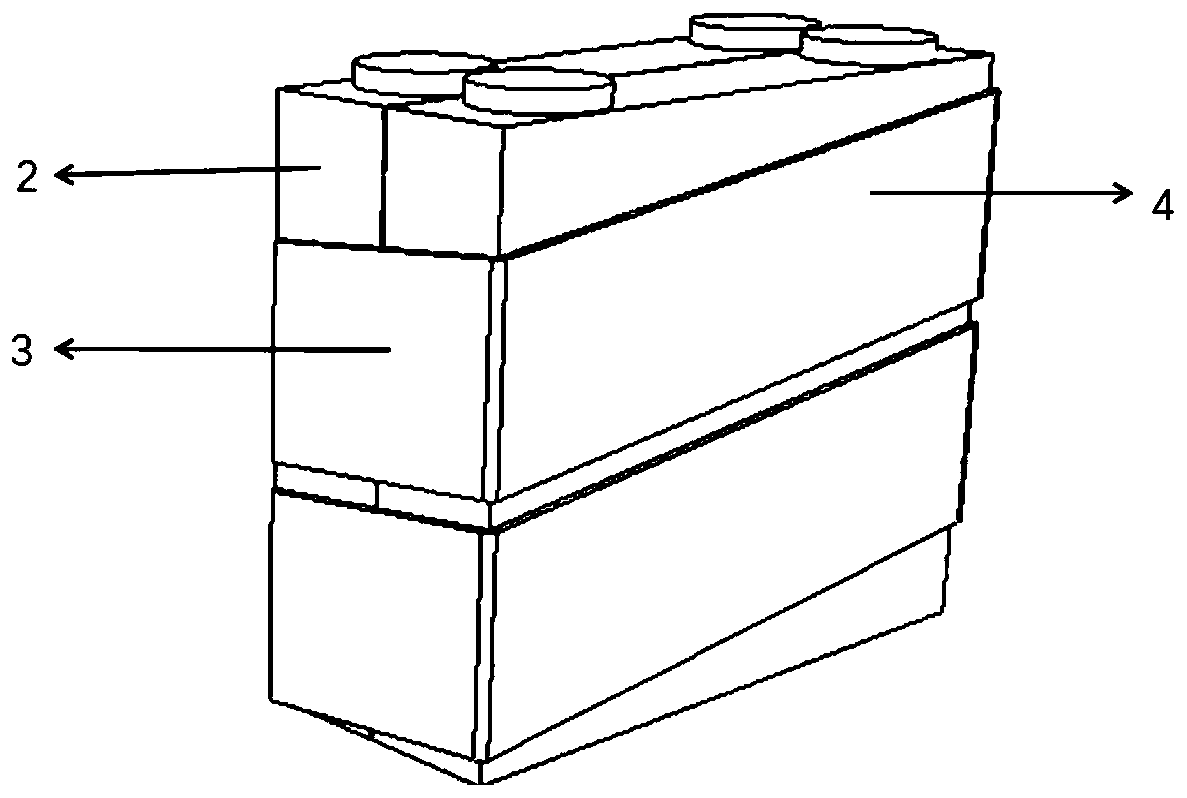

[0042] Such as Figure 1-10 As shown, a dry-wet separation vertical battery pack liquid-cooled thermal management system in this embodiment includes a battery pack and a liquid-cooled plate-tube heat exchanger 7 attached to the outer shell 6 of the battery pack. The battery pack is formed by stacking two single cells 1 and three battery modules 2 in sequence, one at the front and one behind each of the single cells 1, and three battery modules 2 are sandwiched between them, and a total of eight cells are connected in series. The single cell 1 and the battery module 2 can be replaced with a soft-packed battery module composed of a combination of soft-packaged single cells with a structural strength shell on the outside. Each battery cell is placed vertically, with the battery electrodes facing upwards, and the surface of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com