Overturning device for full-automatic high-speed circular sawing machine

A fully automatic, circular saw machine technology, applied in sawing machine devices, metal sawing equipment, metal processing, etc., can solve problems such as inability to guarantee, and achieve the effect of large driving force, normal operation, and low noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

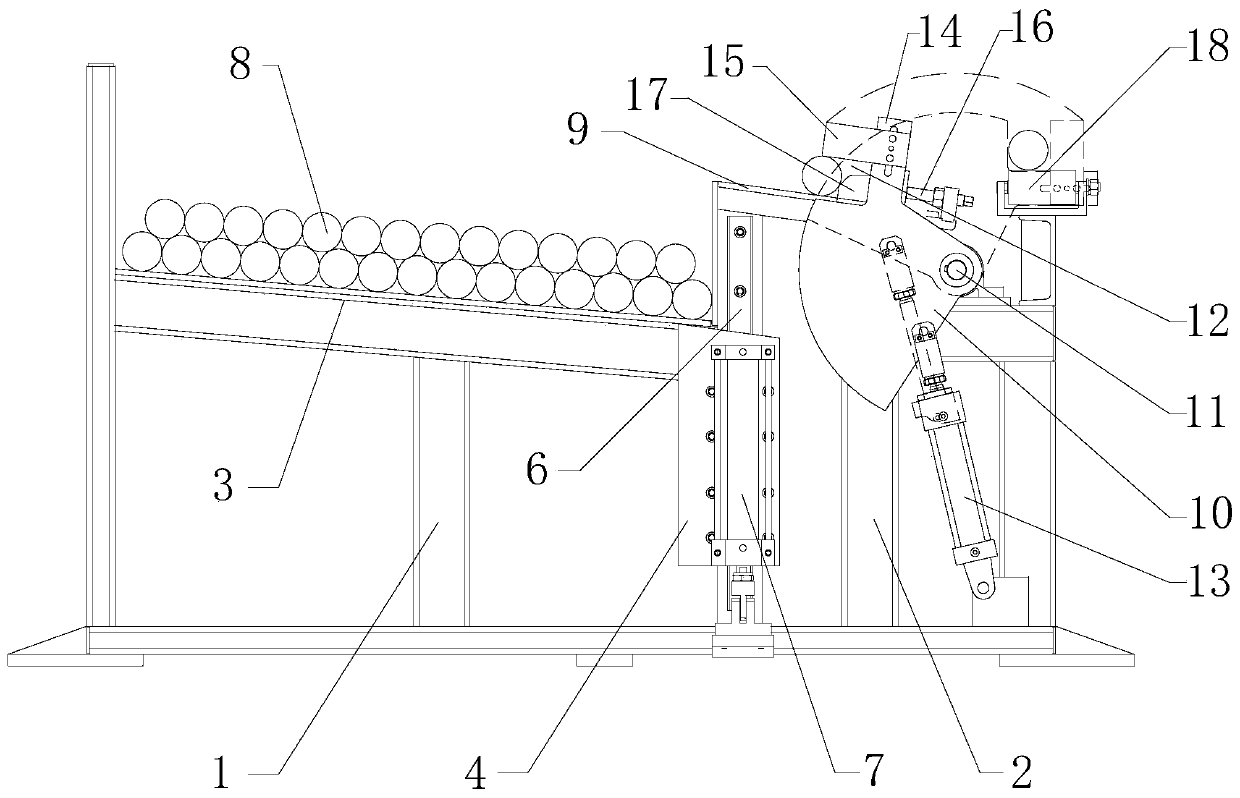

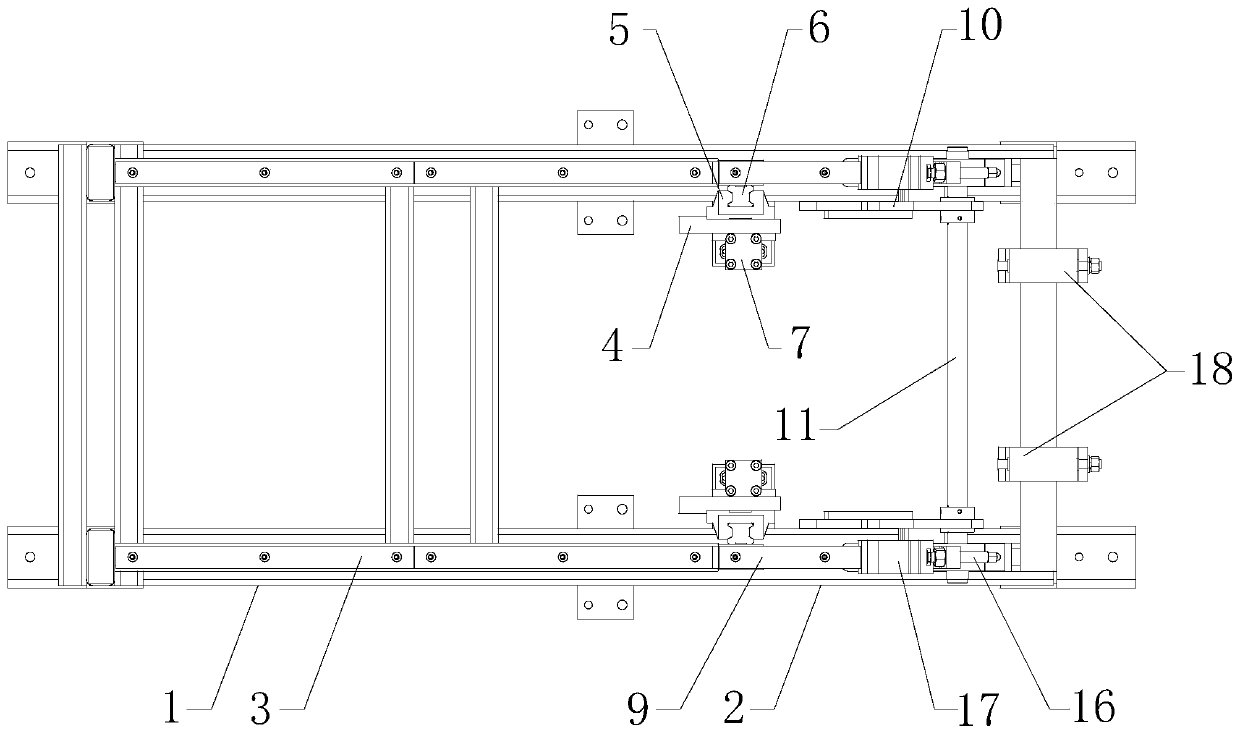

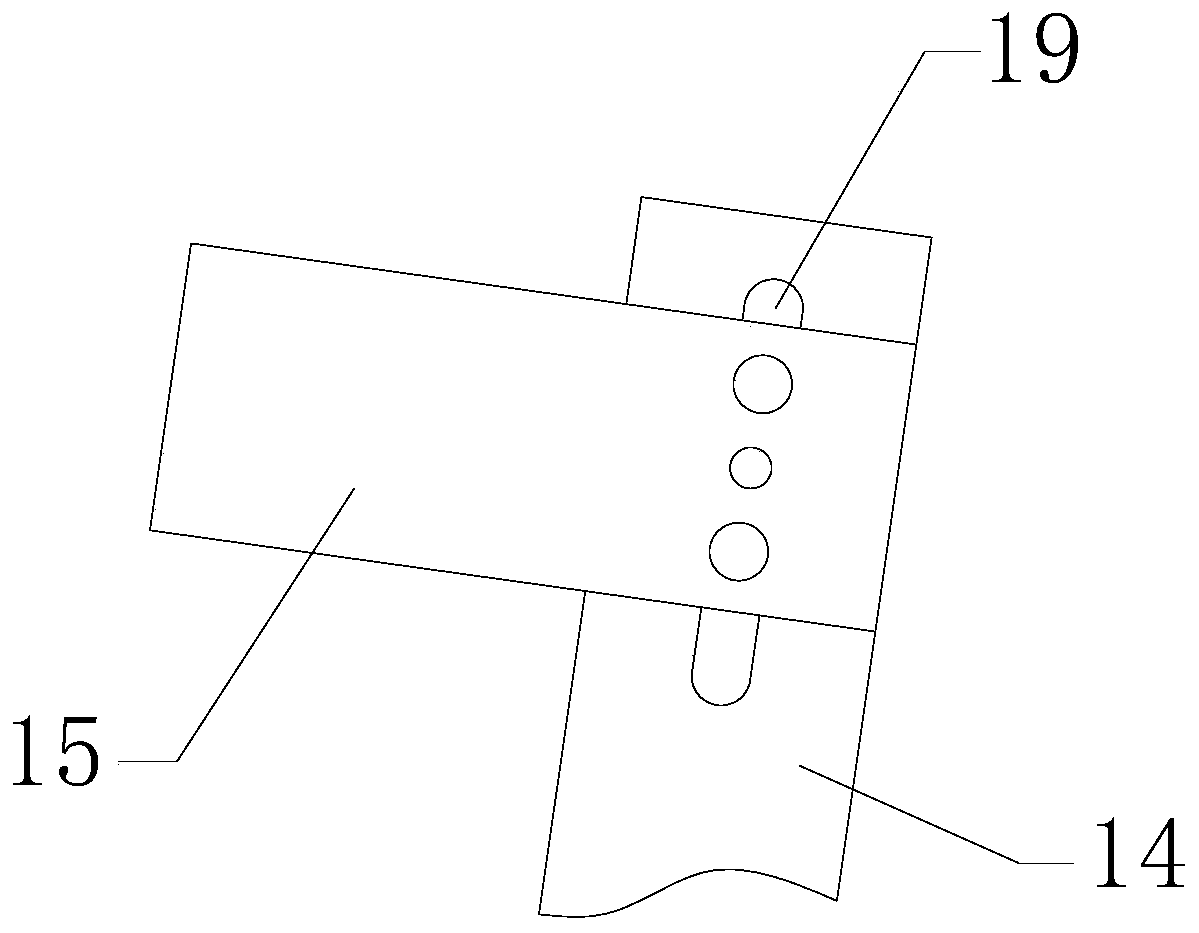

[0031] like figure 1 and figure 2 As shown, the full-automatic high-speed circular saw machine turning device includes a storage mechanism, a feeding mechanism and a turning mechanism, and the charging mechanism feeds the bar stock 8 stored on the storage mechanism to the turning mechanism, Then the bar stock 8 is turned over on the roller 18 by the turning mechanism, and the roller 18 is driven by a motor (not shown in the figure), and the bar stock 8 is laterally output. The stock storage mechanism includes a stock rack 1 and a stock track 3 , the two storage rails 3 are installed on both sides of the top of the storage rack 1 along the length direction of the storage rack 1, and a plurality of bars 8 are loaded on the storage rail 3, and the upper surface of the storage ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com