Tab laser welding equipment

A laser welding and pole ear technology, applied in laser welding equipment, welding equipment, welding equipment and other directions, can solve the problems of insufficient discharge current, excessive welding burr, insufficient pole piece foil and pole lug tension, etc. Welding problems and the effect of ensuring the virtual welding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

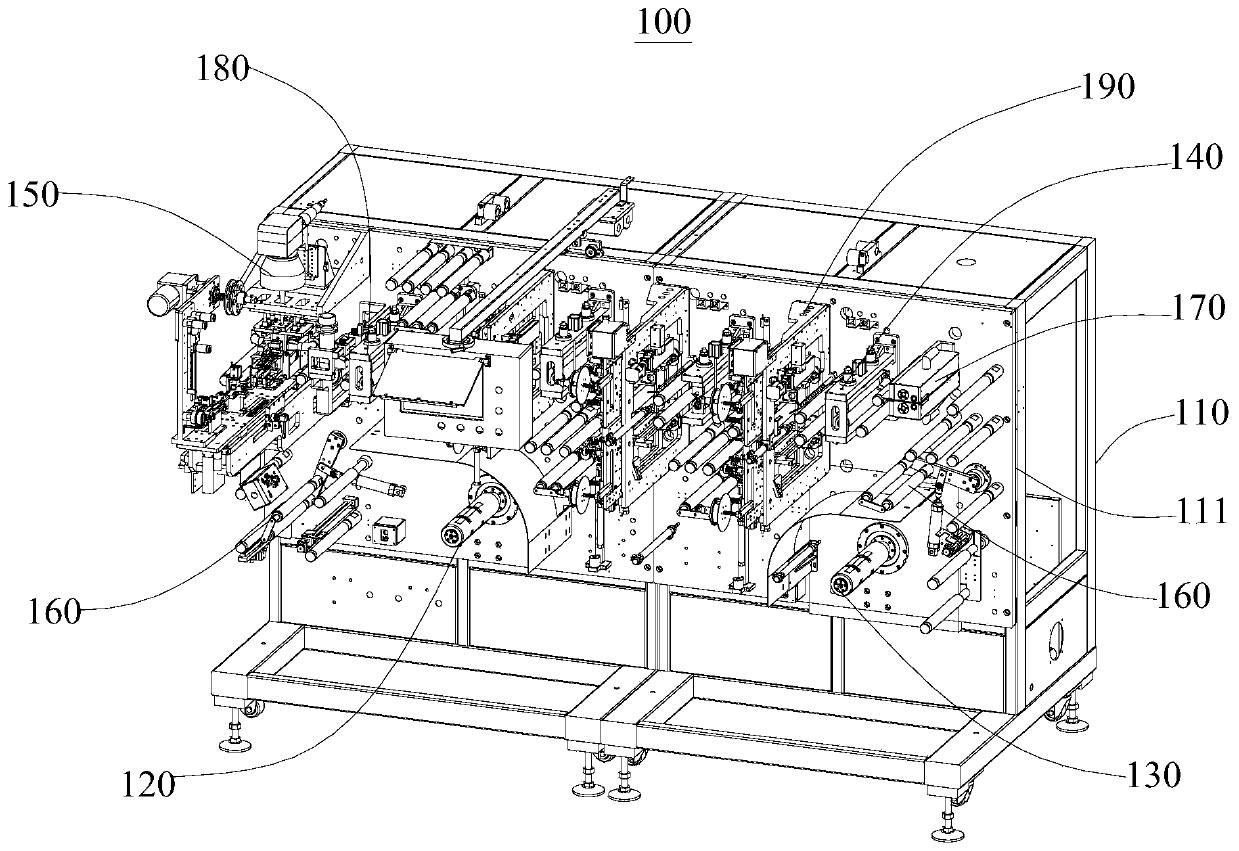

[0039] see in conjunction figure 1 , a laser welding pole lug equipment 100, which uses laser welding to weld the pole piece, the welding effect is good, non-contact welding is adopted, and there is no need to replace the welding head like ultrasonic welding, and it can effectively ensure the false welding rate, after welding Residual rate, tension and other indicators.

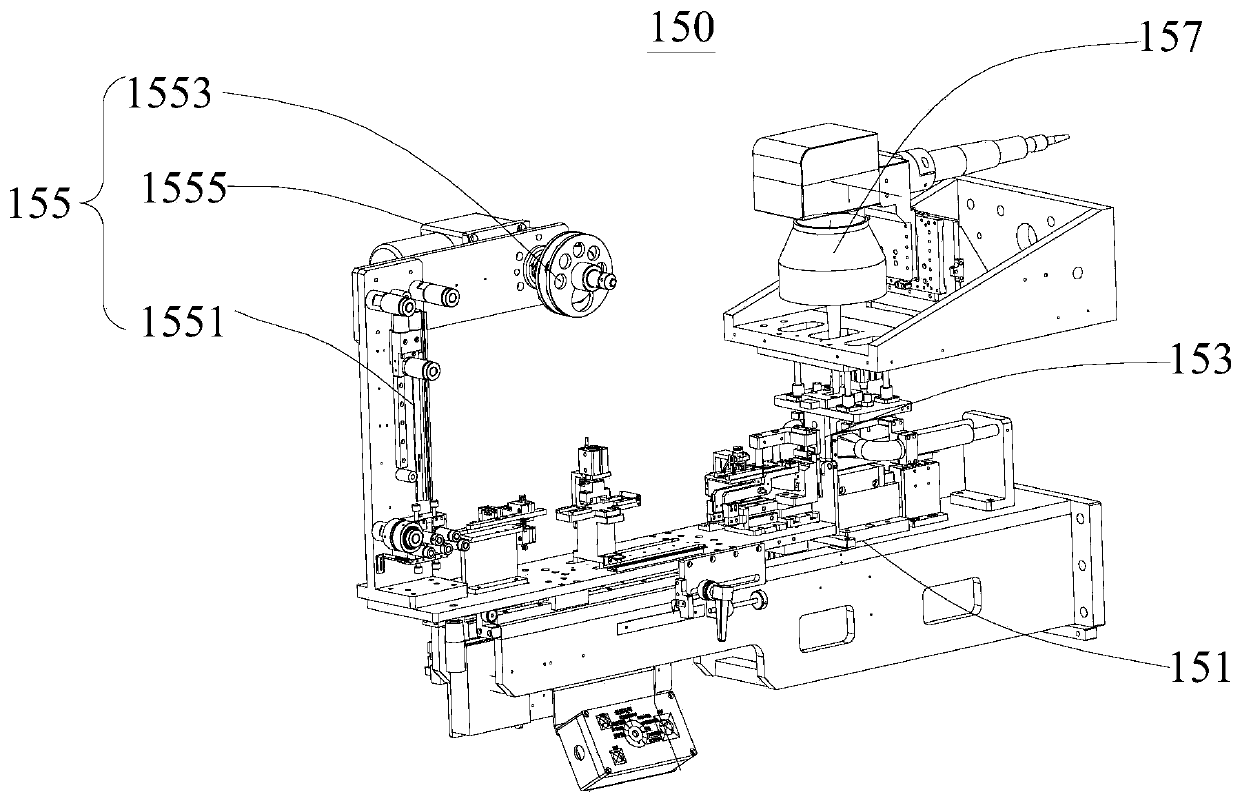

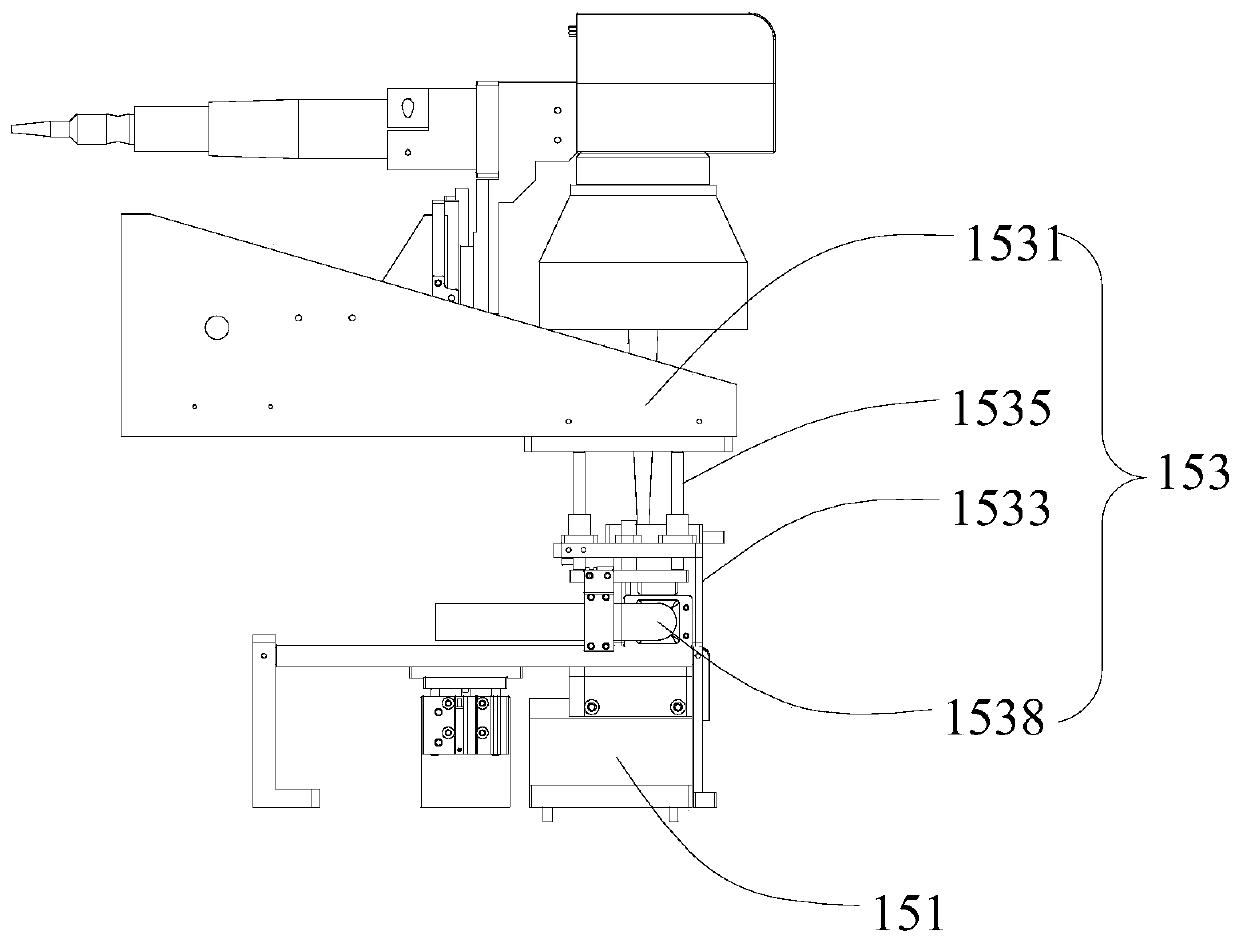

[0040]The laser welding tab equipment 100 provided in this embodiment includes a body 110, an automatic unwinding device 120, an automatic winding device 130, a driving device 140, a tab laser welding device 150, a tension control device 160, a horizontal powder brushing device 170, The air knife dedusting device 180 and the glue sticking device 190, the automatic unwinding device 120 is arranged on the machine body 110, which is used to carry the unwinding pole piece coil material, and the automatic winding device 130 is set on the machine body 110, which is used to carry the winding pole piece Coil materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com