An edge banding strip and installation equipment for easy operation and installation

A technology for installing equipment and edge banding, which is applied to adhesive application devices, other plywood/plywood appliances, manufacturing tools, etc. The effect of avoiding pollution and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments. The following examples or drawings are used to illustrate the present invention, but not to limit the scope of the present invention.

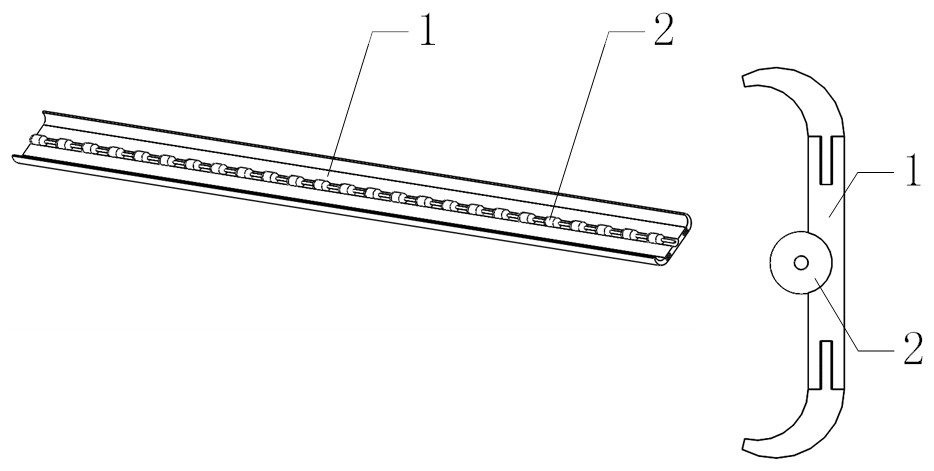

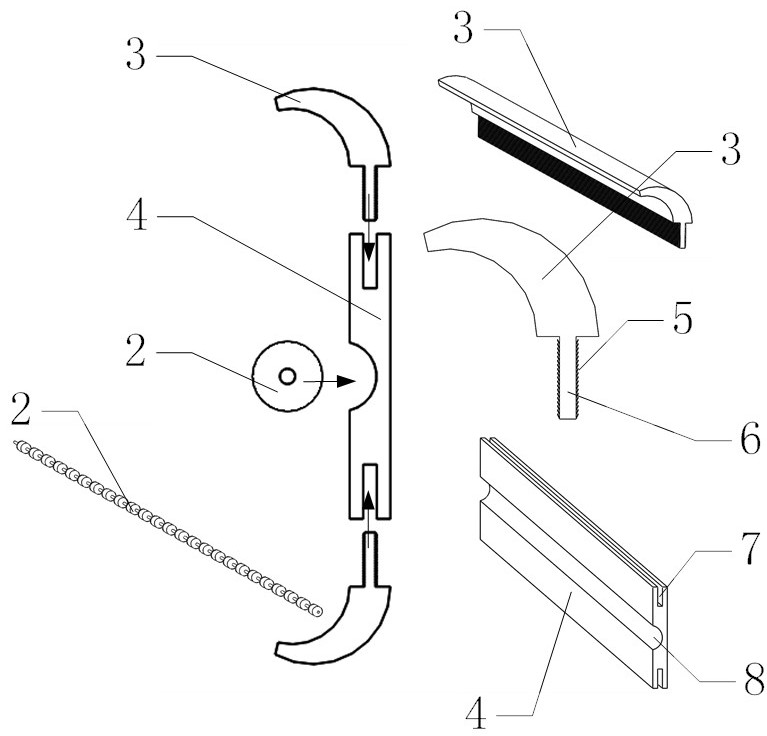

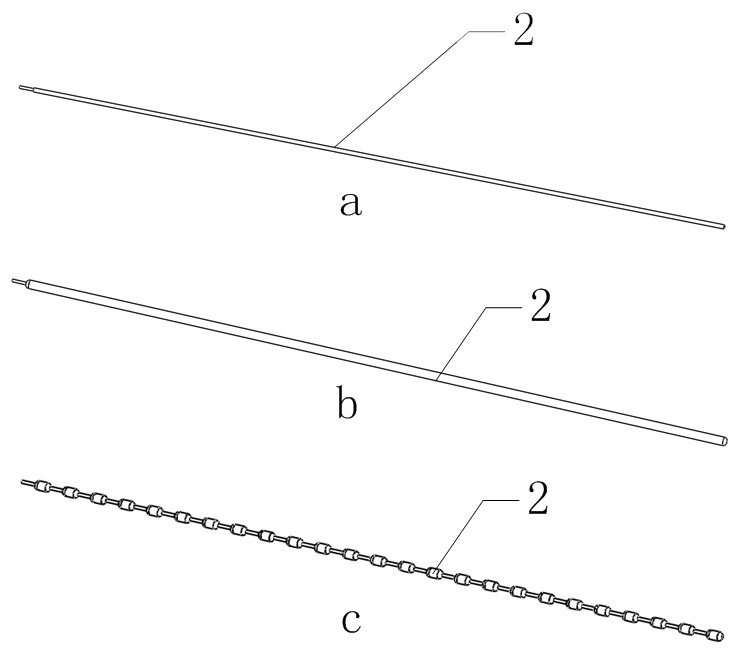

[0042] like figure 1 , 2 As shown, it includes an edge sealing body 4 for applying glue, and buckles 3 installed at both ends of the edge sealing body 4 for being stuck on the wooden board 9. Capsule 2 for storing glue, and the capsule 2 is adhered to the capsule placement groove 8 opened on the edge sealing body 4 through the glue liquid. The above two buckles 3 are rubber. After the edge sealing body 4 is laid flat, the two The tip of the buckle 3 is higher than the capsule 2 in the capsule placement groove 8; such as Figure 4 As shown, the buckle 3 is made of rubber material to prevent bumping, reduce the transportation volume, and facilitate transportation.

[0043] The edge ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com