Composite wing molding and assembly integration mold

A composite material and wing technology, applied in the field of mold manufacturing, can solve the problems of high production cost, consumption, long manufacturing time, etc., achieve high-precision manufacturing and assembly, reduce manufacturing costs, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

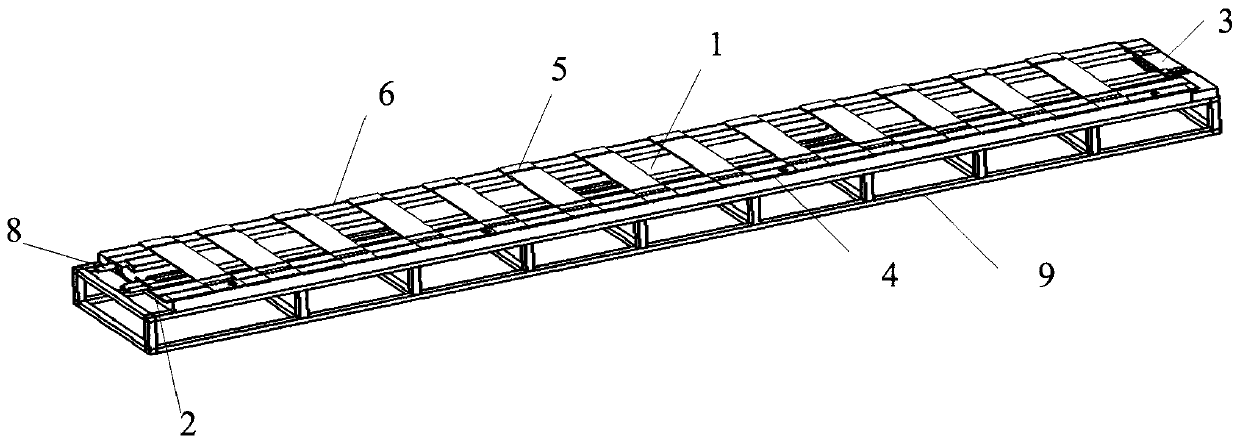

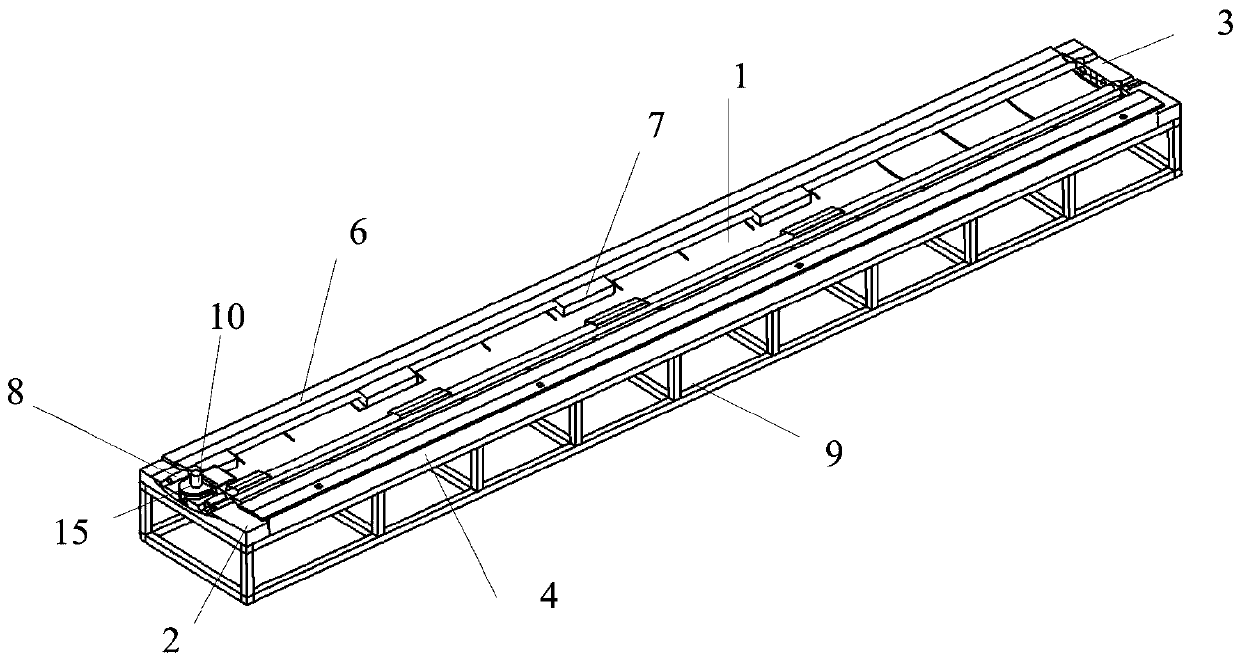

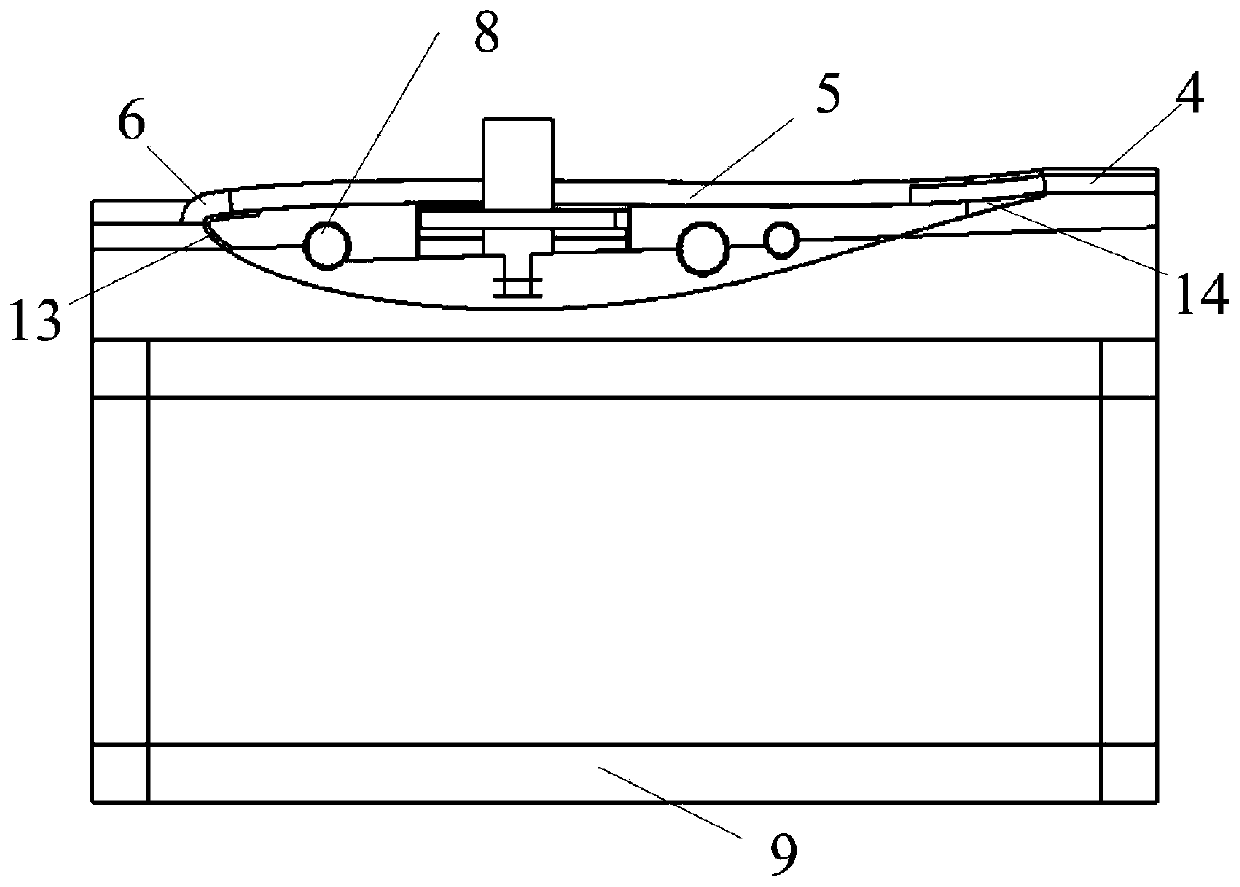

[0032] Substitute wood resin is used as the material of the airfoil surface mold 1. After curing, the main body of the mold 1 is formed. The mold surface is processed by CNC, and finally the surface is corrected and gel-coated to complete the manufacture of the airfoil surface mold. The root clip 2 and the end clip 3 are also manufactured in this way. The mold support 9 adopts steel structure welding, and the airfoil surface mold 1 is fixed on the mold support 9 .

[0033] Processing of the trailing edge forming press plate: FRP composite material is used as the main material, and wood resin is bonded on the forming surface, and then the trailing edge forming surface is processed by CNC machine, and the surface paint is sprayed.

[0034] Processing of rib positioning platen: FRP composite material is used as the main material, and wood resin is bonded on the forming surface, and then the outer forming surface of the wing rib of the composite airfoil is processed by CNC machini...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap