Floating tip cone device for vertical spool take-up machine

A wire take-up machine and floating top technology, which is applied in transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as increased vibration of the fuselage, safety accidents, and parts that are easy to hurt operators, and achieve The effect of avoiding safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

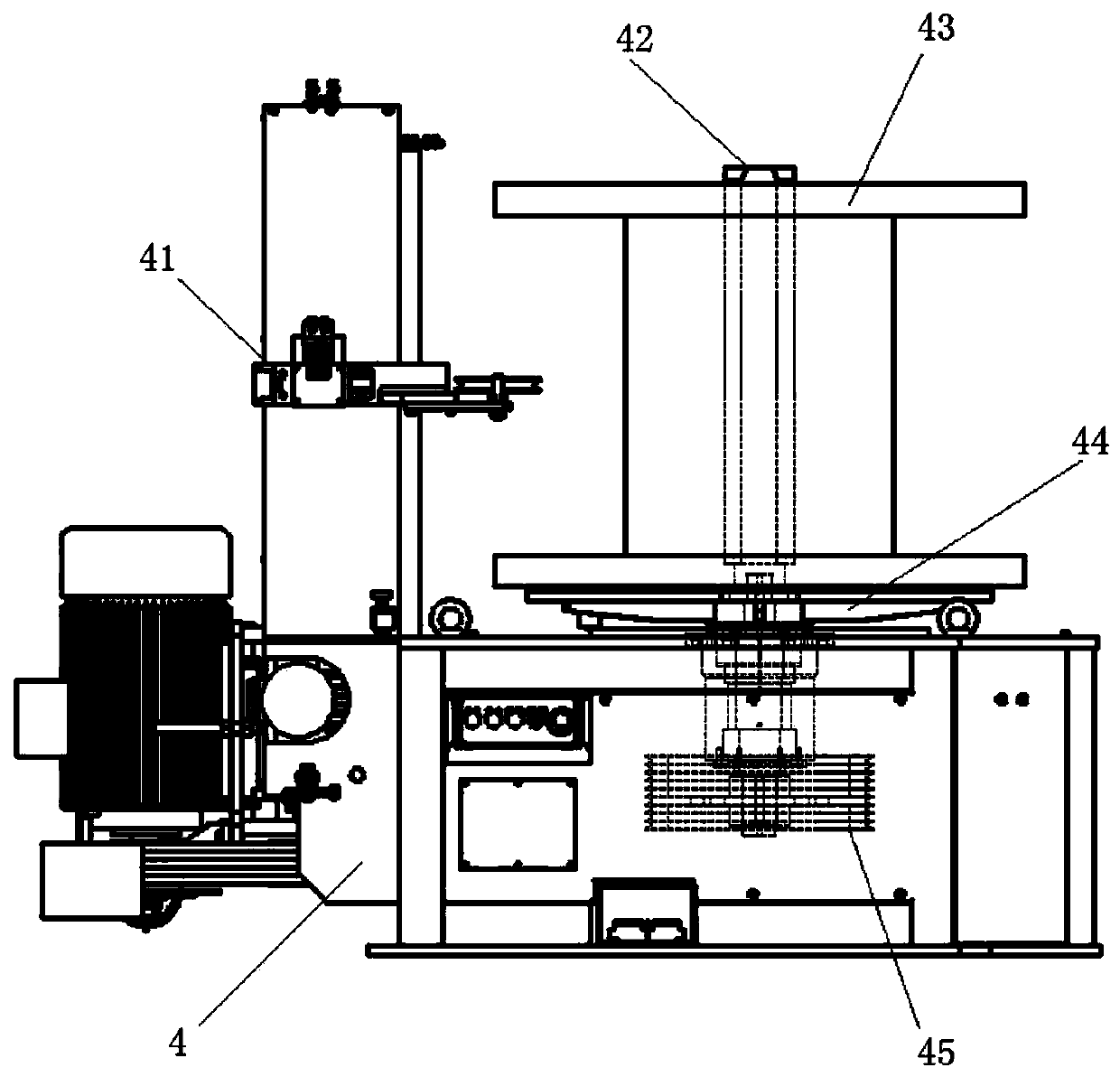

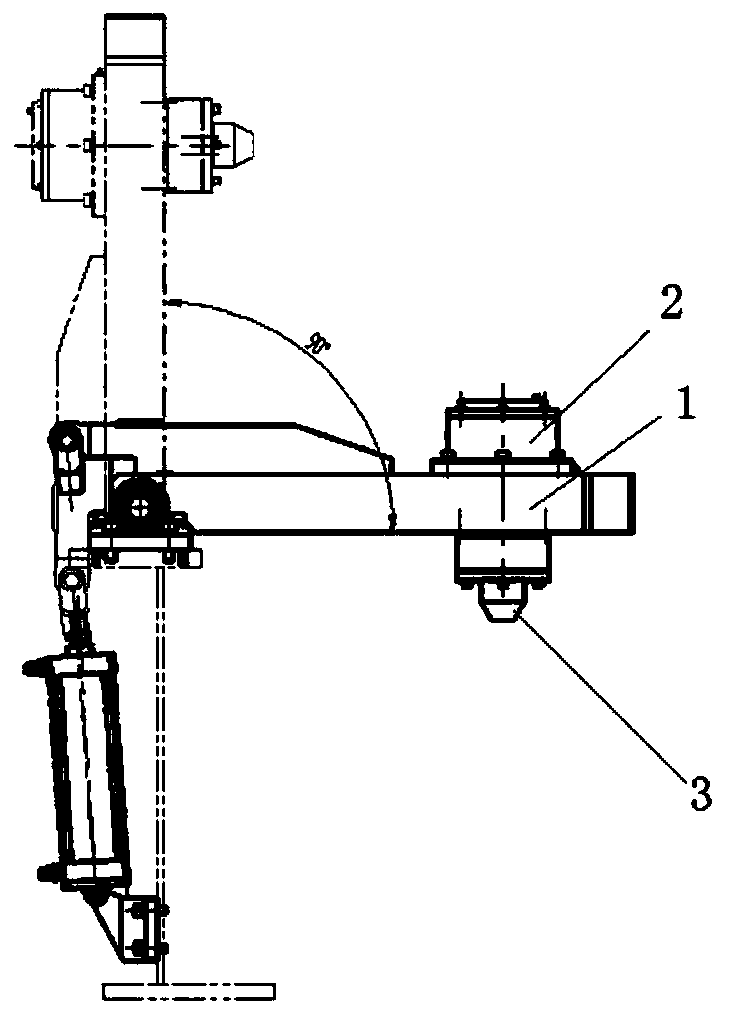

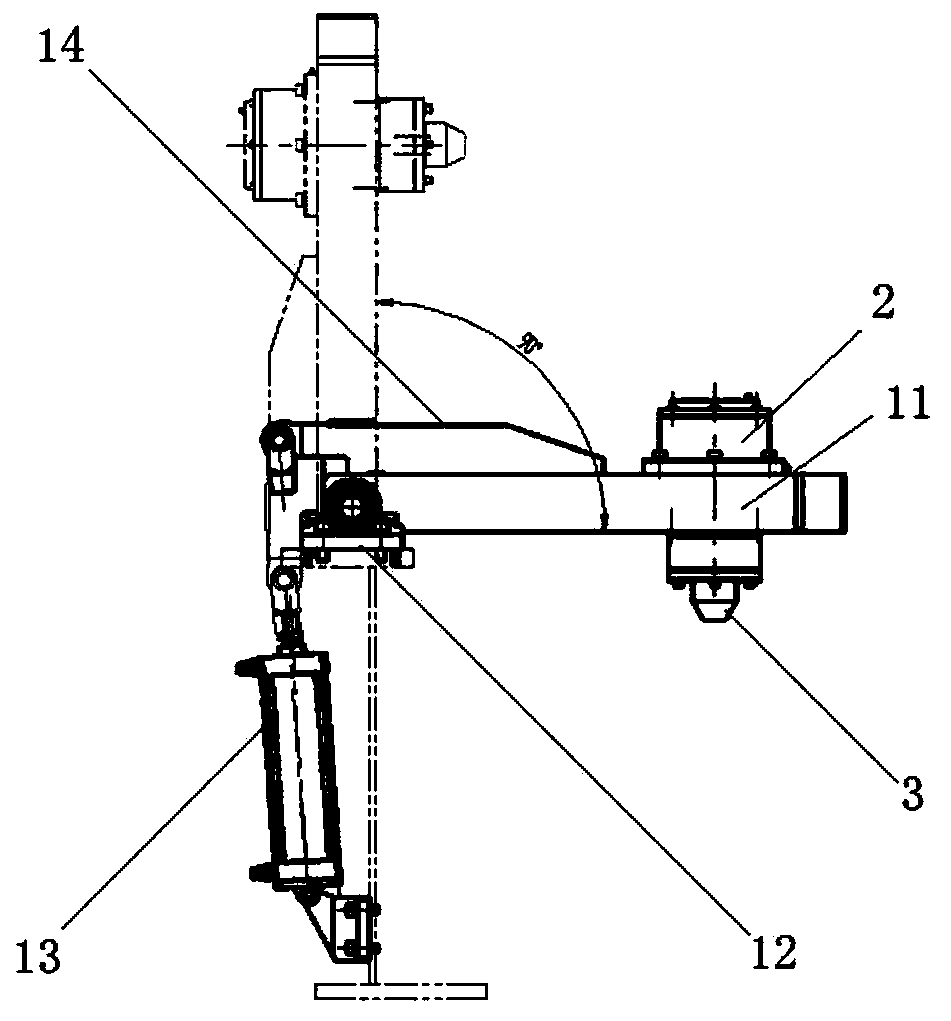

[0031] Such as Figure 1-6 shown.

[0032] A floating top cone device for a vertical I-wheel take-up machine according to the present invention, which includes a bracket 1; a sleeve frame 2, which is fixedly installed on the sleeve frame 2 at the end of the bracket 1; a rotating shaft assembly 3, which is rotatably installed on the sleeve The rotating shaft assembly 3 inside the seat 2 , the rotating shaft assembly 3 includes a rotating shaft 31 .

[0033] The support 1 is fixedly mounted on the wire take-up machine 4, ensuring that the support 1 is perpendicular to the central axis of the centering mandrel 42, and the end of the rotating shaft 31 is in contact with the through hole on the centering mandrel 42 to ensure that the central axis of the rotating shaft 31 is in line with the fixed axis. The central axes of the central ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com