Coal and biomass co-pyrolysis reaction device and method

A technology for a reaction device and biomass, which is applied to the co-pyrolysis device of coal and biomass, and the co-pyrolysis reaction field of coal and biomass, can solve the problems of low synergy effect and different pyrolysis intervals, so as to improve the product yield. And the effect of oil quality, simple and convenient process, oil yield and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0038] Embodiment 2, a method for coal and biomass co-pyrolysis reaction, using the coal and biomass co-pyrolysis reaction device described in Example 1, the steps are as follows:

[0039] (1) Weigh a certain amount of coal and put it into the sample basket 3, put the biomass in the biomass feeder 4 and seal it, and connect the experimental device;

[0040](2) Feed nitrogen gas from the air inlet of rubber plug 9; open tubular heating furnace 2 to set the temperature rise program for heating; monitor the temperature of the co-pyrolysis reaction coal sample in real time through thermocouple thermometer 11; set the temperature rise rate of tubular heating furnace Set at 1-60°C / min;

[0041] (3) When the coal sample reaches the set temperature of 300-600°C, open the feeding valve, and the biomass falls into the sample basket 3 through the feeding pipe 8, and co-pyrolyzes with the coal being pyrolyzed; the co-pyrolysis reaction The final temperature is set at 600-800°C;

[0042]...

Embodiment 3

[0043] Example 3, a comparative experiment of coal and biomass co-pyrolysis reaction:

experiment example

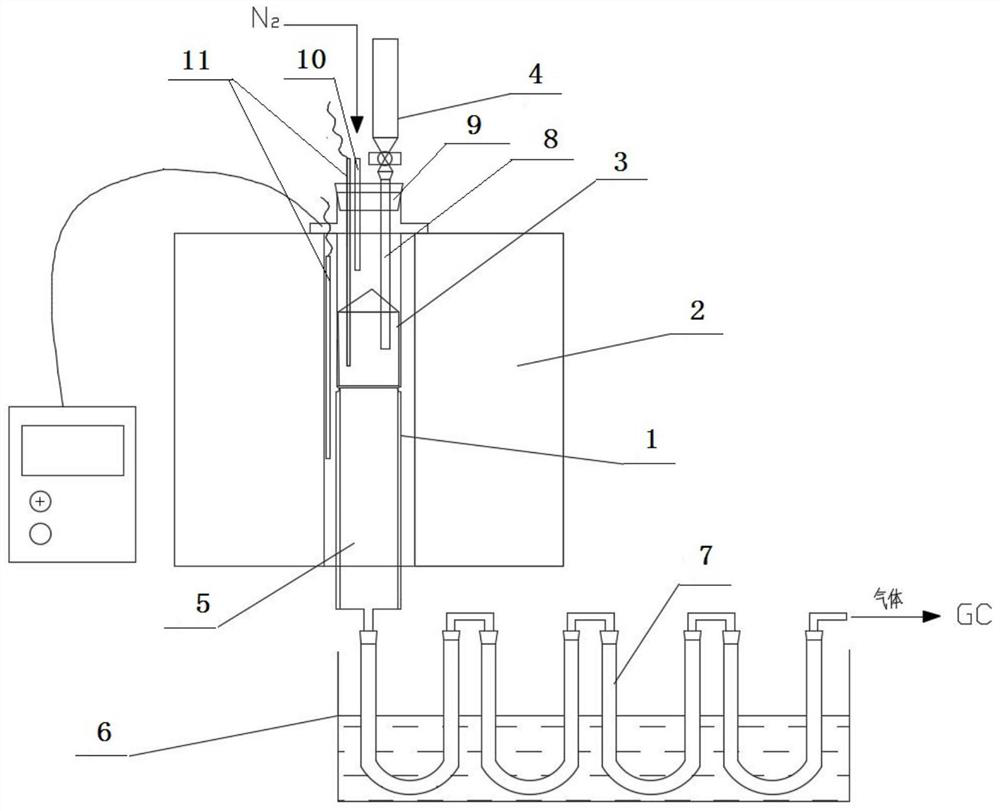

[0044] Experimental example: refer to figure 1 , using the coal and biomass co-pyrolysis reaction device described in embodiment 1, wherein:

[0045] The tube heating furnace is an ordinary programmable tube heating furnace with an inner diameter of 20 mm and a length of 300 mm.

[0046] The inner diameter of the reaction pipe body 3 is 13.75mm, the wall thickness is 1mm, and the length is 400mm. The inner diameter of the sample basket 13 is 12mm, the wall thickness is 0.75mm, and the length is 100mm. The bottom of the sample basket 13 is perforated, and the copper mesh plate at the bottom can prevent coal dust and biomass Fall, guaranteed experimental results.

[0047] The condensing device is composed of 4 U-shaped tubes in series. The U-shaped tubes are placed in an ice-water bath, and the purpose of multi-stage condensation is to fully condense the tar in the pyrolysis gas to ensure the calculation of the yield and the determination of the gas phase composition.

[0048]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com