Industrialization method of oxygen pressure acid leaching of primary uranium molybdenum ore

A technology of oxygen pressure acid leaching and molybdenum ore, which is applied in the field of oxygen pressure acid leaching of primary uranium and molybdenum ore, can solve the problems of low resource utilization rate, low molybdenum leaching rate, and high environmental risk, so as to improve resource utilization rate and improve leaching The effect of high efficiency and safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with embodiment the present invention is further introduced:

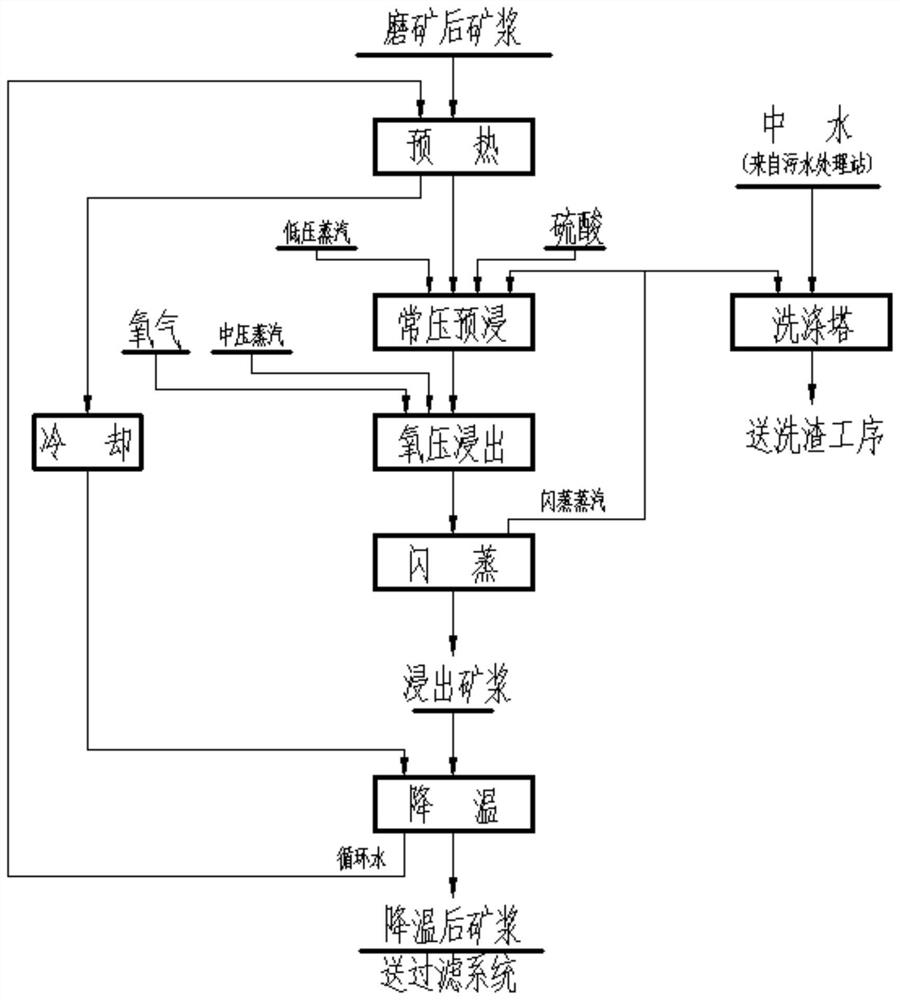

[0025] An industrial method for oxygen pressure acid leaching of primary uranium molybdenum ore, comprising the following steps:

[0026] Step 1. Grinding, grading, and pulping the uranium-molybdenum symbiotic raw ore to obtain an ore pulp with a solid content of 30%-42% and a particle size of -100 mesh ≥ 95%;

[0027] Step 2, add 92.5% - 98% concentration of sulfuric acid pre-soaking in the pulp; use the recovered steam to preheat to 80 - 90 ℃;

[0028] Step 3. The preheated pulp is continuously sent into the horizontal pressurized reactor through the pulp pump. In the first stage of the horizontal pressurized reactor, it is continuously stirred and directly heated to above 140°C with steam, and oxygen is introduced at the same time. , Control the pressure of the reactor to 0.6--0.95MPa, and the second stage of the reactor starts to stabilize the temperature at 160--180°C. Reactor oxy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com