Inner liner underwater bubbling detection device and method

A detection device and liner technology, applied in the neural learning method, by detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, etc., can solve the problem of high labor cost, high noise, and unreliable results to avoid on-site operations, reduce labor costs, and reduce interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

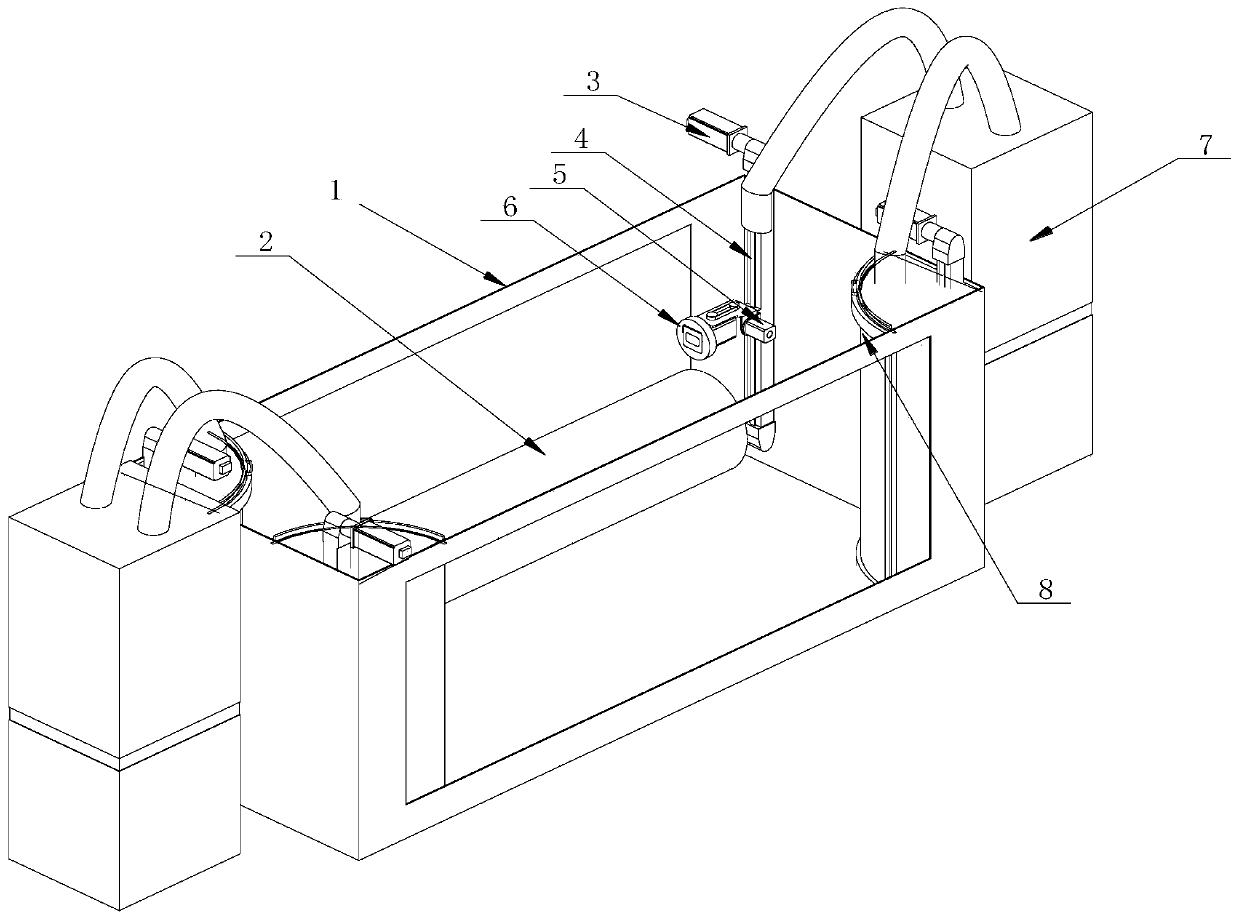

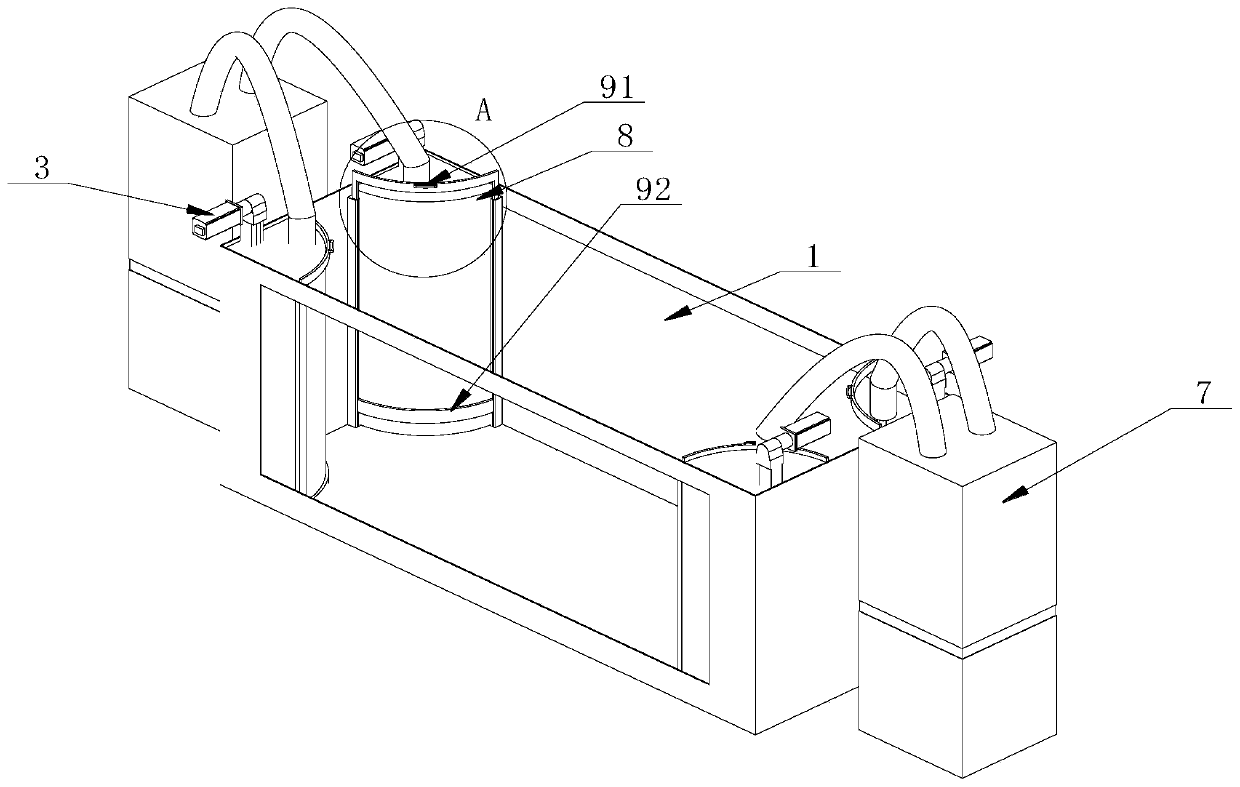

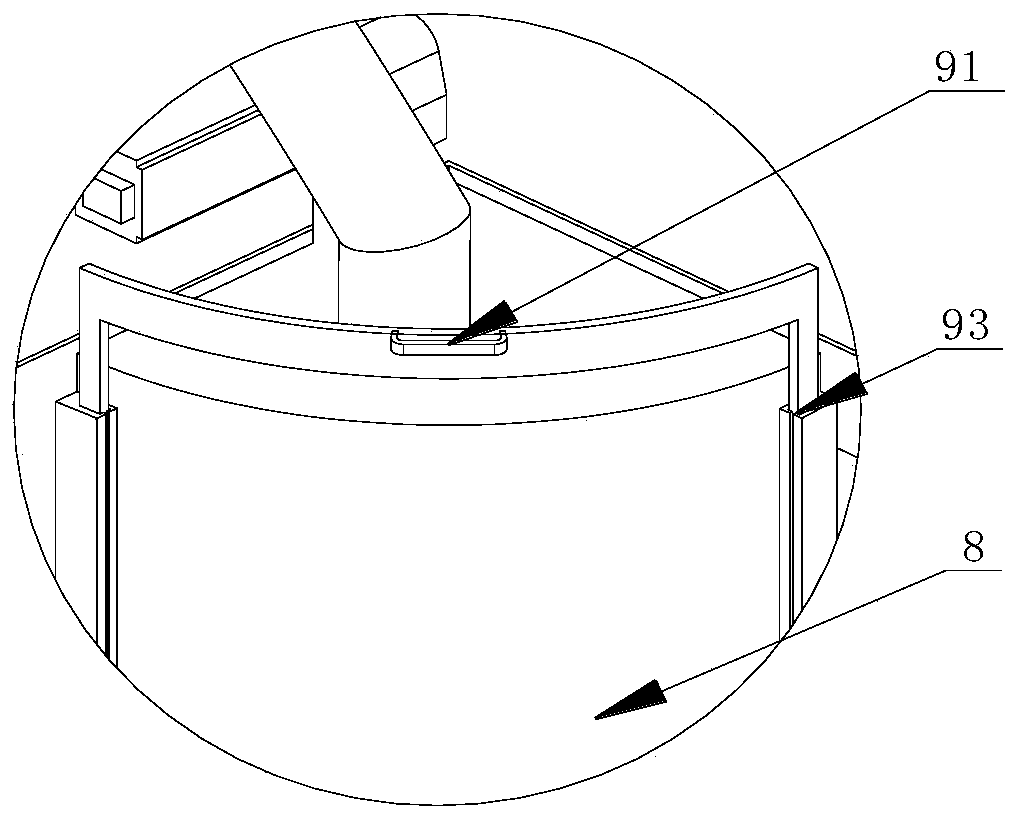

[0033] Such as Figure 1-3 As shown, the underwater bubbling detection device for the inner tank includes an isolation cavity 8 provided on the cylinder body 1 for immersing the inner tank 2, and the isolation cavity 8 is transparent and isolated from the liquid inside the cylinder body 1. A camera 6 is arranged in the isolation cavity 8, and the camera 6 is connected to an external signal processing module, and the signal processing module is connected to a host computer with a display. Optimally, the cylinder body 1 is also transparent.

[0034] A guide rail 4 is arranged in the isolation cavity 8 , and the camera 6 moves up and down in the isolation cavity 8 .

[0035] There are multiple isolation chambers 8, several of which are vertically arranged at the corners of the cylinder block 1, the guide rail 4 is vertically arranged in the isolation chamber 8, and the guide rail 4 is provided with a camera 6 sliding on the guide rail 4. The slider also includes a first driver ...

Embodiment 2

[0041] Using the method of the above-mentioned liner underwater bubbling detection device, the signal processing module includes a host computer, including the following steps:

[0042] The initial position of the camera 6 needs to be adjusted according to different liners 2 .

[0043] S1. When the liquid in the cylinder body 1 is not disturbed, turn on the camera 6 and the signal processing module, adjust the position of the camera 6, and obtain an image; after placing the liner 2 in the cylinder body 1, let it stand for the first set time; The first set time is 5 minutes.

[0044] S2. Move the camera 6 to a set position to acquire an image; take out the liner 2 from the cylinder body 1 . Before detecting the bubbles, first check the condition of the liner 2 entering and exiting the pool, and wait accordingly to avoid the interference of the suspended matter in the water at the industrial site (similar to the shape and size of the bubbles) to the bubble detection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com