Automatic organic matter water washing liquid separation device and liquid separation method thereof

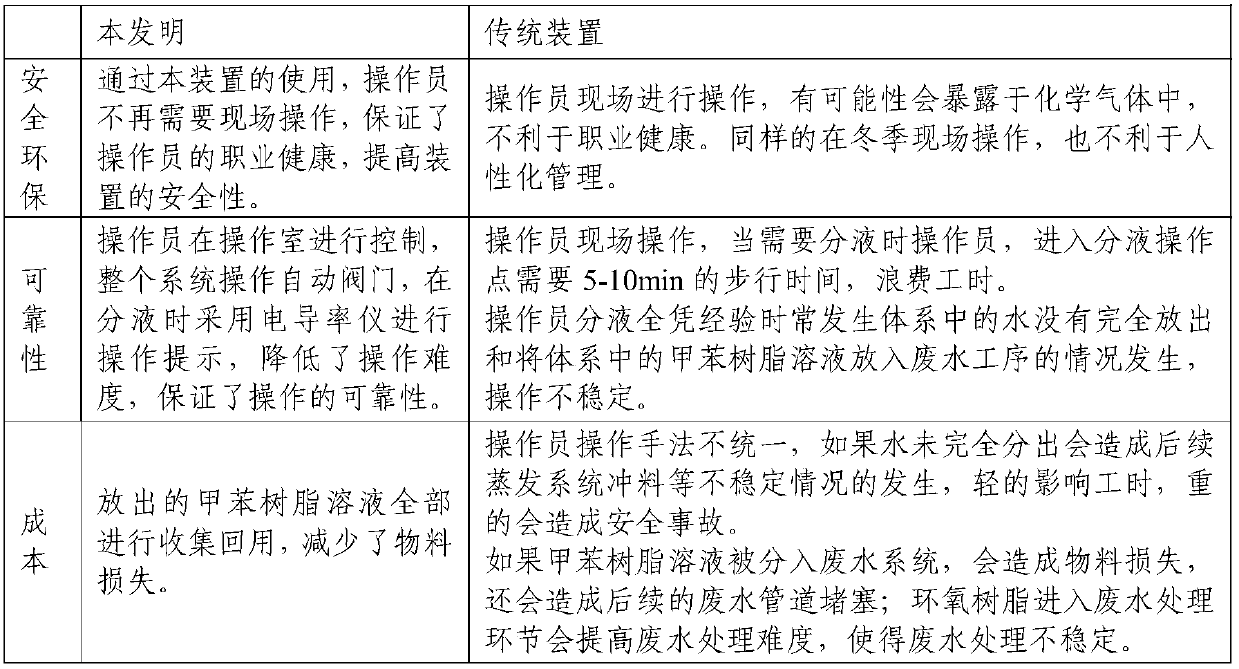

An organic matter and liquid separation technology, which is applied in separation methods, chemical instruments and methods, liquid separation, etc., can solve problems such as dependence on operator experience, material loss, waste of labor, etc., to improve process control capabilities, avoid on-site operations, and improve Effect of dispensing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

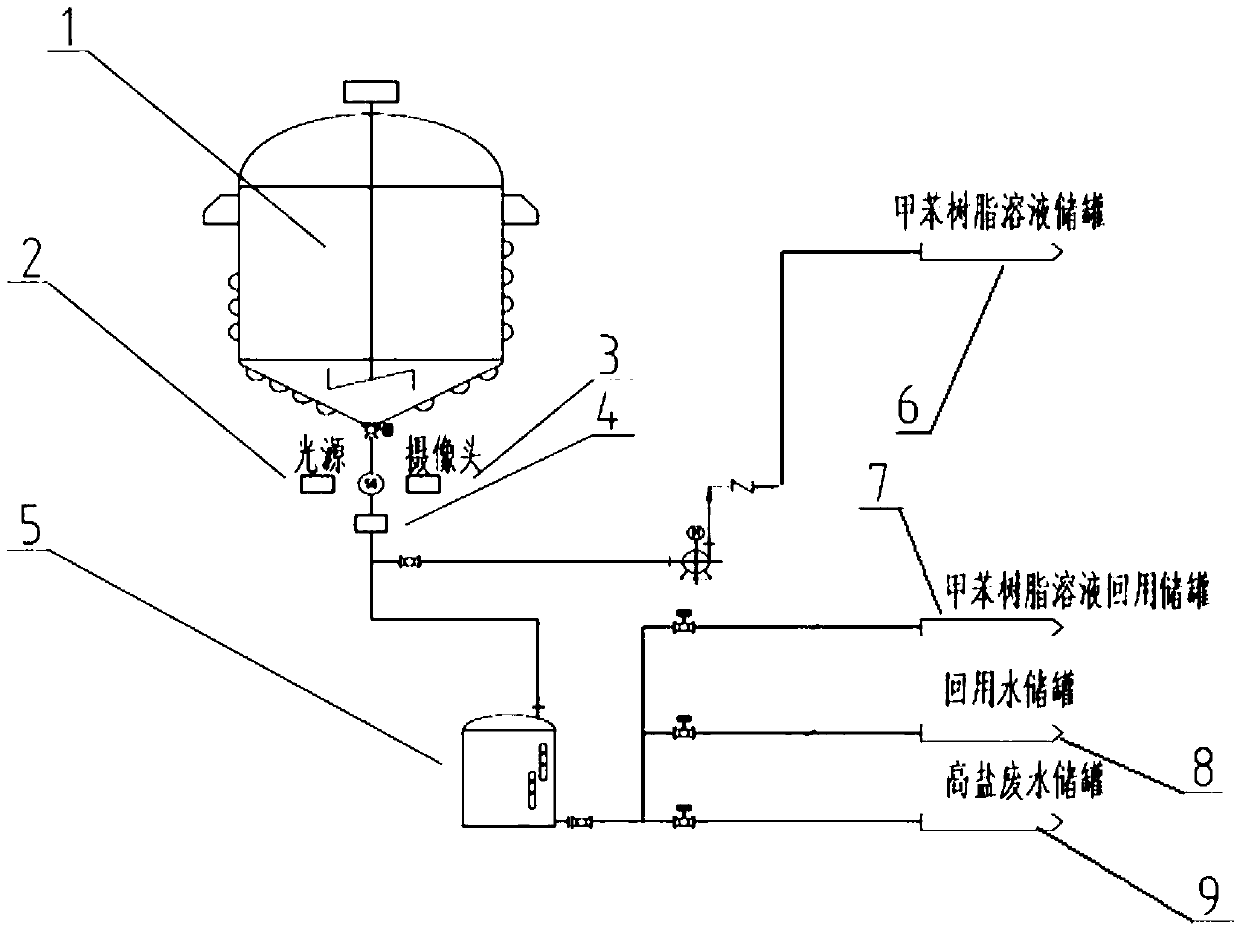

[0028] Embodiment 1 A kind of automatic liquid separation device of liquid epoxy resin water washing process

[0029] An automatic liquid separation device for the washing process of liquid epoxy resin, comprising: a detection unit located at the liquid outlet of the washing kettle 1, a branch pipe between the detection unit and the connecting pipe of the toluene resin collection tank 6, and a branch pipe connected to the branch pipe. Liquid recovery device, and background control unit.

[0030] Using the above device, the detection unit collects the detection index of the effluent from the washing tank and transmits it to the background control unit; according to the detection index, the background control unit controls the automatic cut-off valve of the liquid separation recovery device, so as to realize the separation of the mixed liquid in the washing process in the washing tank Collect work.

[0031] Preferably, the detection unit is a detection device grasped by those s...

Embodiment 2

[0035] Embodiment 2 A kind of tertiary amine oil washing process automatic liquid separation device

[0036] An automatic liquid separation device for the tertiary amine oil washing process, comprising: a detection unit located at the liquid outlet of the water washing kettle 1, a branch pipe arranged between the detection unit and the connecting pipe of the tertiary amine oil collection tank 6, and a branch pipe connected to the branch pipe. Liquid recovery device, and background control unit.

[0037] Using the above device, the detection unit collects the detection index of the effluent from the washing tank and transmits it to the background control unit; according to the detection index, the background control unit controls the automatic cut-off valve of the liquid separation recovery device, so as to realize the separation of the mixed liquid in the washing process in the washing tank Collect work.

[0038] Preferably, the detection unit is a detection device known by t...

Embodiment 3

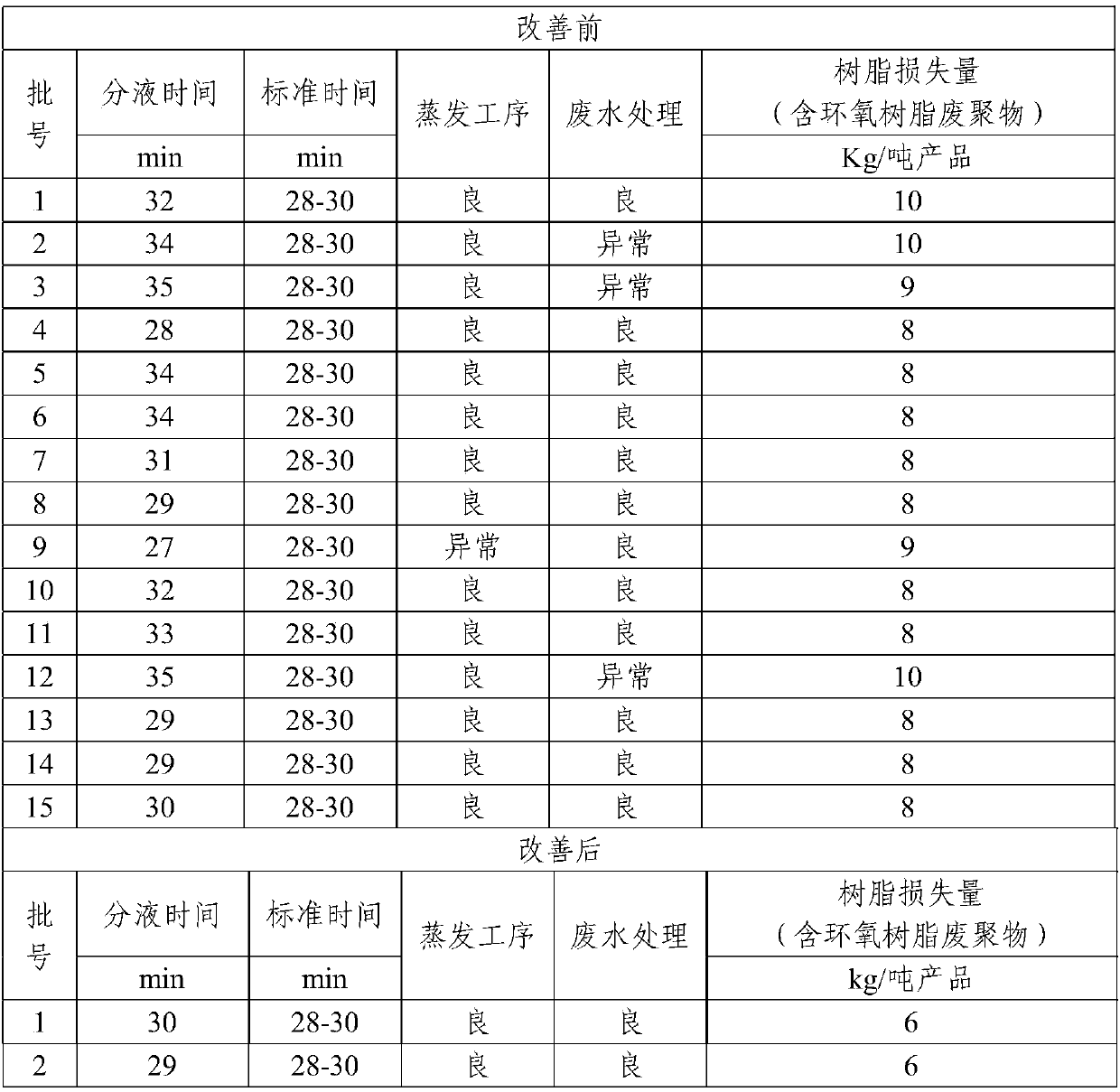

[0042] Embodiment 3 One kind utilizes the device described in embodiment 1 to carry out automatic liquid separation method to liquid epoxy resin washing liquid (DCS carries out automatic control according to the reading of conductivity meter)

[0043] The crude epoxy resin obtained in the upstream synthesis process contains a large amount of salt and by-products, and a washing process is required; specifically: add an appropriate amount of toluene and an appropriate amount of water to the crude epoxy resin, open the washing tank, stir and let it stand for a certain period of time. time, start to wash for the first time; after the first washing, the high-salt wastewater formed needs to be separated (that is, liquid separation collection) out of the washing kettle.

[0044] The liquid separation collection is as follows: collecting the effluent of the washing kettle, collecting the indicators of the effluent at the same time, and remotely transmitting the indicators to the backgr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com