Flow production line of fresh air ventilator

A production line and new fan technology, which is applied in the testing of machine/structural components, assembling machines, measuring devices, etc., can solve the problems of low assembly efficiency and high work intensity, and achieve high qualification rate, high degree of automation, labor saving and storage. effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

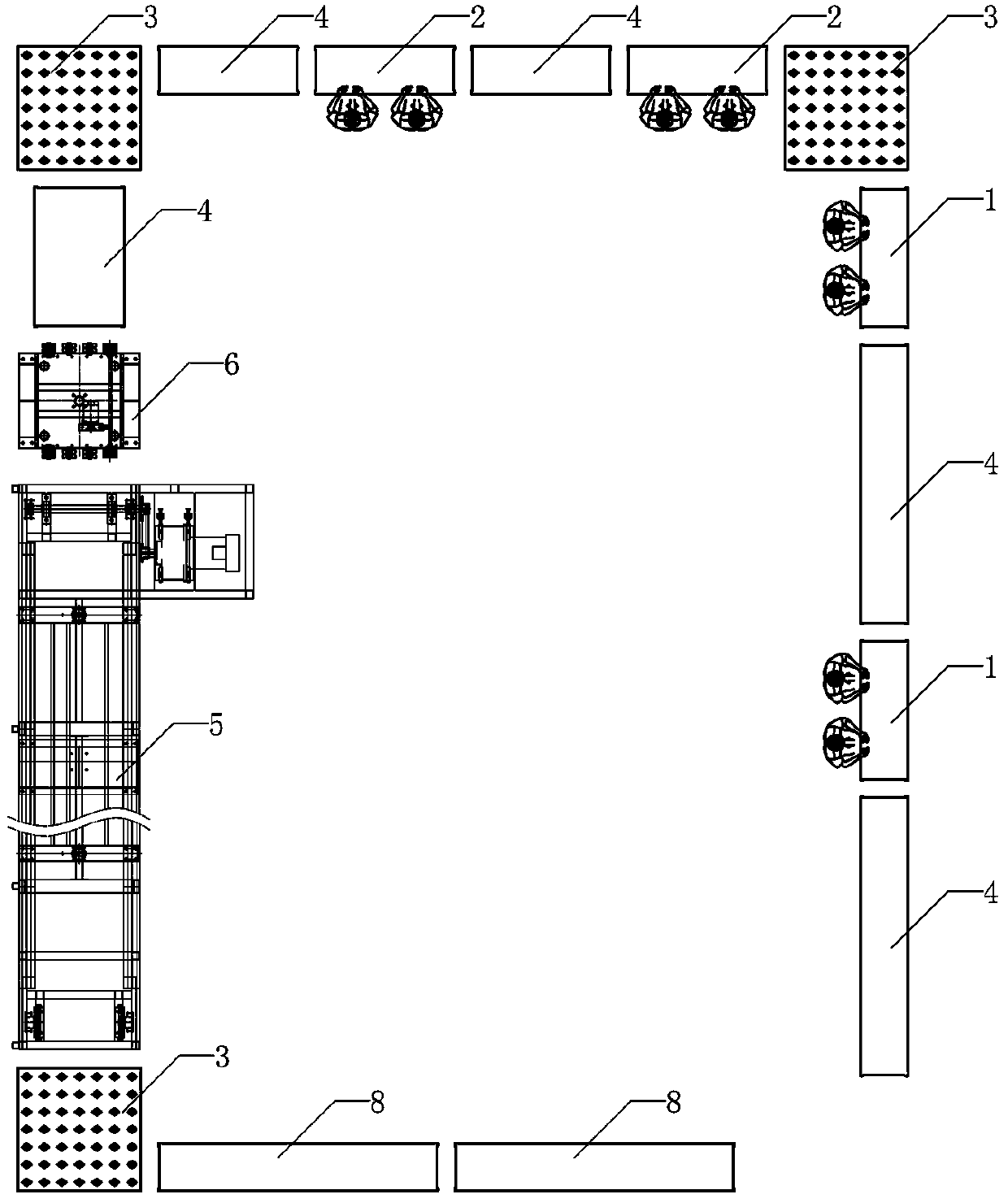

[0025] refer to figure 1 As shown, a flow production line of a new fan disclosed by the present invention includes a horizontal turning conveyor line connected end to end, a vertical turning conveying line, an aging line 5 and a finished product output line, wherein the horizontal turning conveying line and the up and down turning conveying line are vertically connected On both sides of the bull's-eye table 3, the up-down turning conveying line and the aging line 5 are vertically connected on both sides of the bull's-eye table 3, and the aging line 5 and the finished product output line are vertically connected on both sides of the bull's-eye table 3, so that the entire assembly line constitutes a "loop". "Form, product input and output form a closed loop.

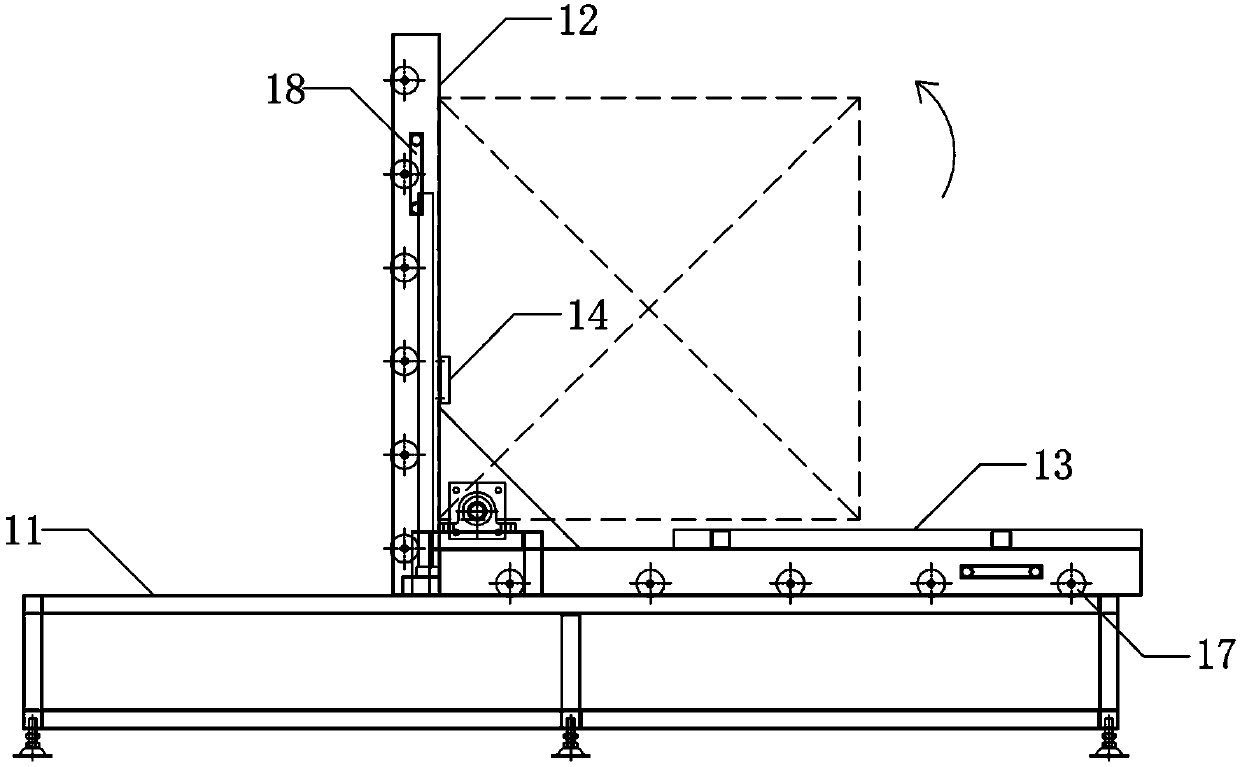

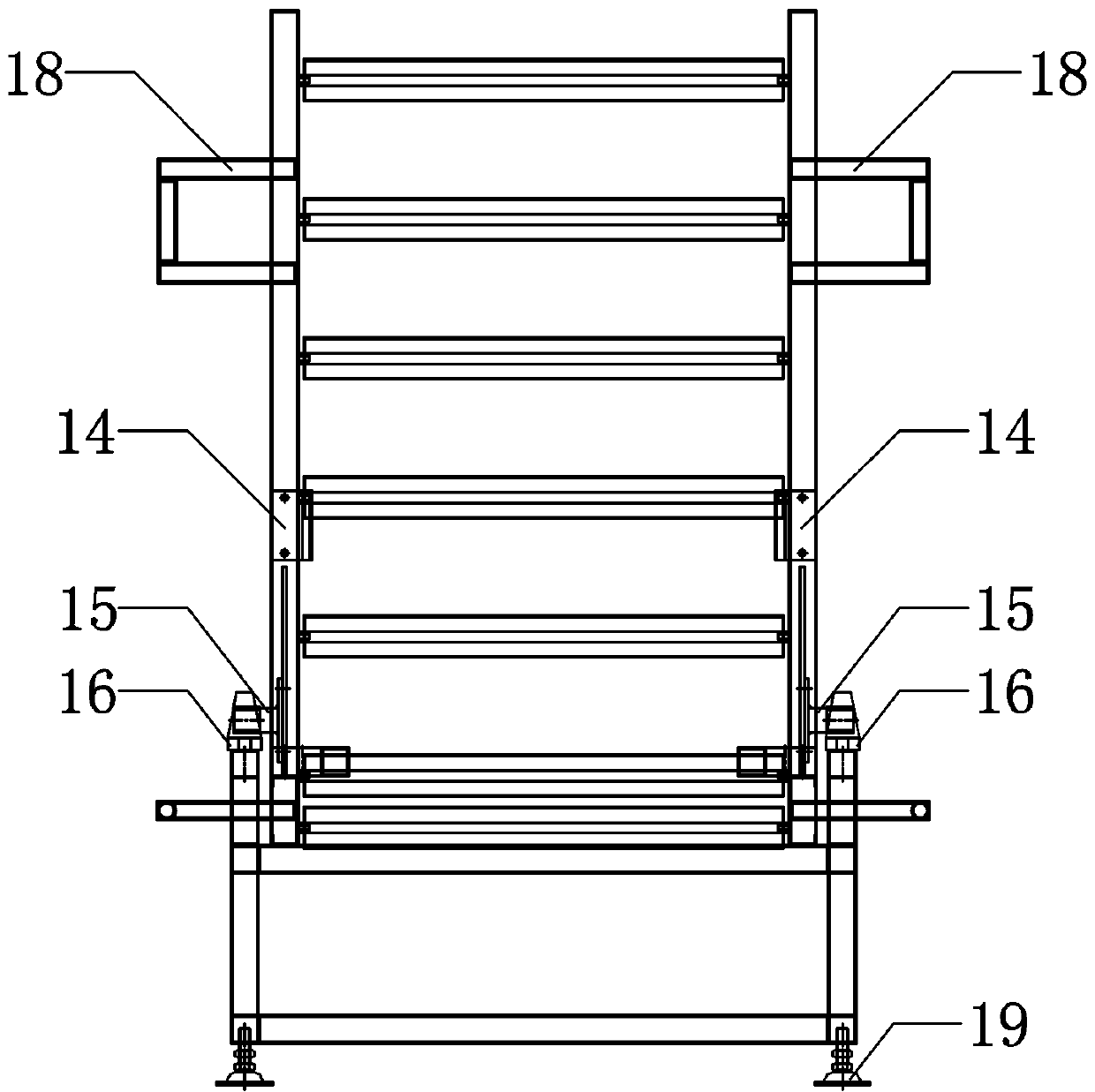

[0026] refer to figure 2 , image 3As shown, the horizontal turning conveyor line of the present i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com