Automatic deposition system and method

A kind of cladding and automatic technology, applied in the direction of metal material coating process, coating, etc., can solve the problems of waste of manpower and materials, backward control method of cladding, etc., achieve fast processing, reduce communication time, save cladding materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

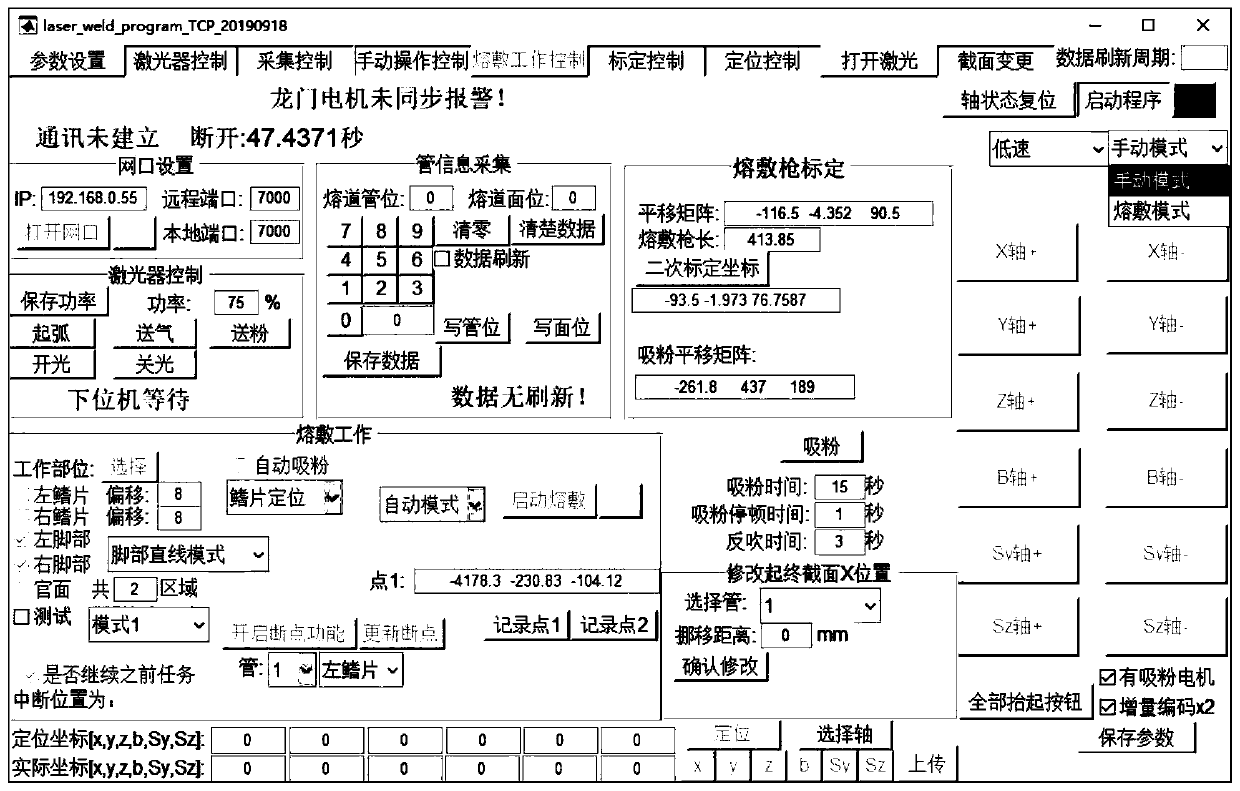

[0022] Embodiment 1: An automatic cladding system according to this embodiment, including a manual operation control module, a positioning control module, a laser scanning module and a cladding work control module;

[0023] The manual operation control module is used to input the direction key control signal, and the welding gun head moves to the welding position of the part to be welded according to the direction key control signal to realize rough positioning;

[0024] The positioning control module is connected with the manual operation control module. When the rough positioning is completed, the positioning control module is used to input the coordinates of the welding position of the parts to be welded and the adjustment angle of the welding gun head, and the welding gun head moves to the position to be welded. Position coordinates, and according to the adjustment angle, adjust the cladding gun head to be perpendicular to the position to be clad to complete precise positio...

specific Embodiment approach 2

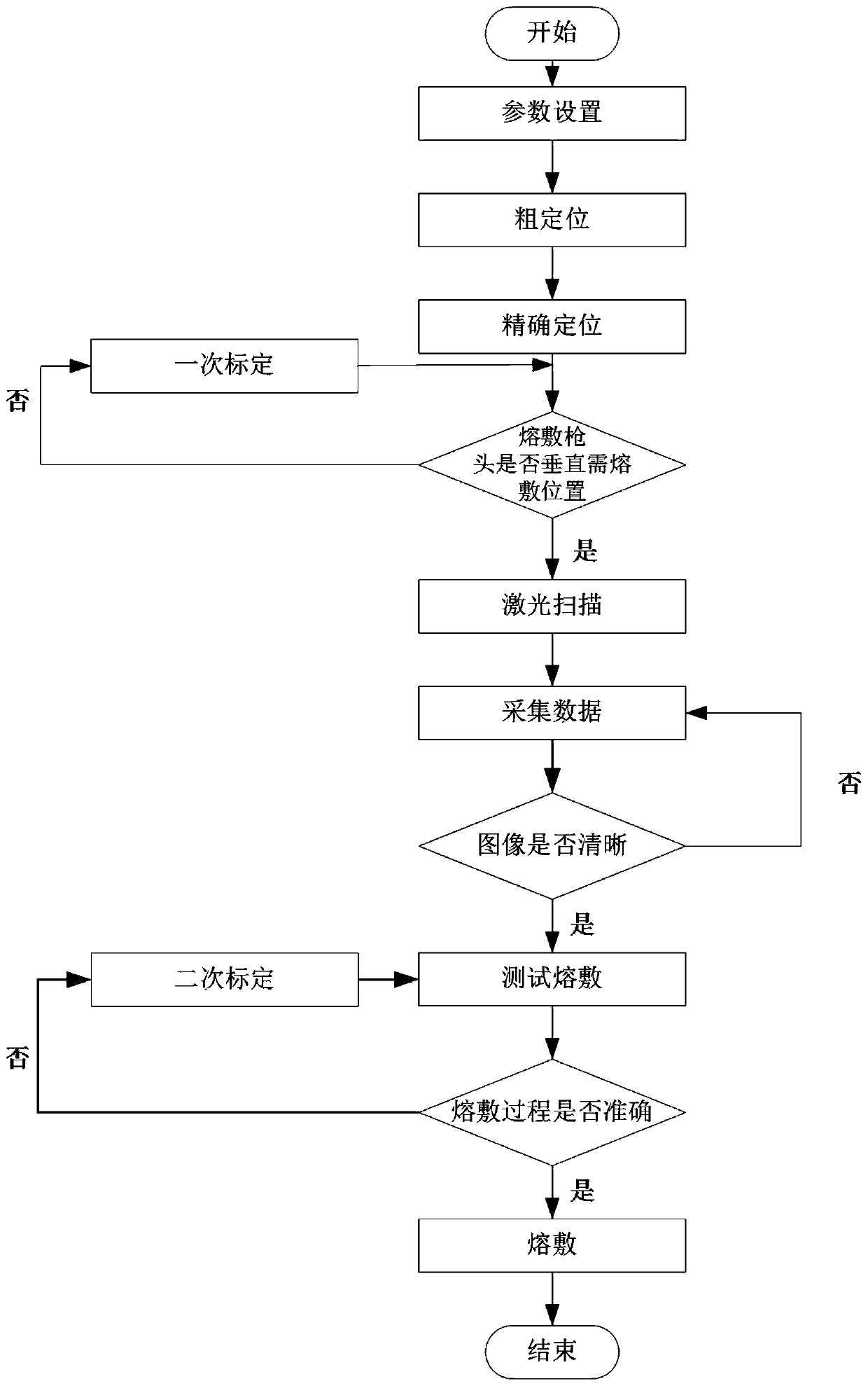

[0036] Specific embodiment two: an automatic cladding method of this embodiment, the method includes the following steps:

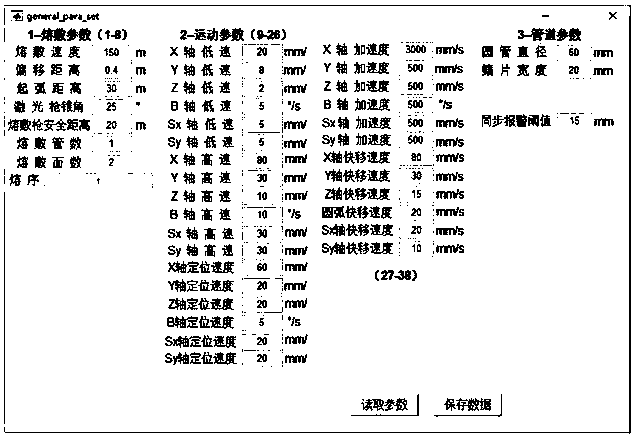

[0037] Step 1: Input the manual moving speed signal and positioning speed signal of the cladding gun head;

[0038] Step 2: Input the direction key control signal, and the welding gun head moves to the welding position of the part to be welded according to the direction key control signal and manual movement speed signal, so as to realize rough positioning;

[0039] Step 3: Input the position coordinates of the parts to be welded and the adjustment angle of the welding gun head, the welding gun head moves to the coordinates of the welding position according to the positioning speed signal, and the welding gun head is adjusted to be vertical according to the adjustment angle Complete precise positioning at the position to be deposited;

[0040] Step 4: Use a laser scanner to scan the position of the part to be welded to obtain multiple discrete point maps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com