Radial coaxial integrated high power density inertial energy storage pulse power supply system

A high power density, pulse power supply technology, applied to the shape/style/structure of winding conductors, electromechanical devices, electrical components, etc., can solve the problems of damage to armature windings, high mechanical noise, low power density, etc. Shaft joints, reduce mechanical noise, and improve power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

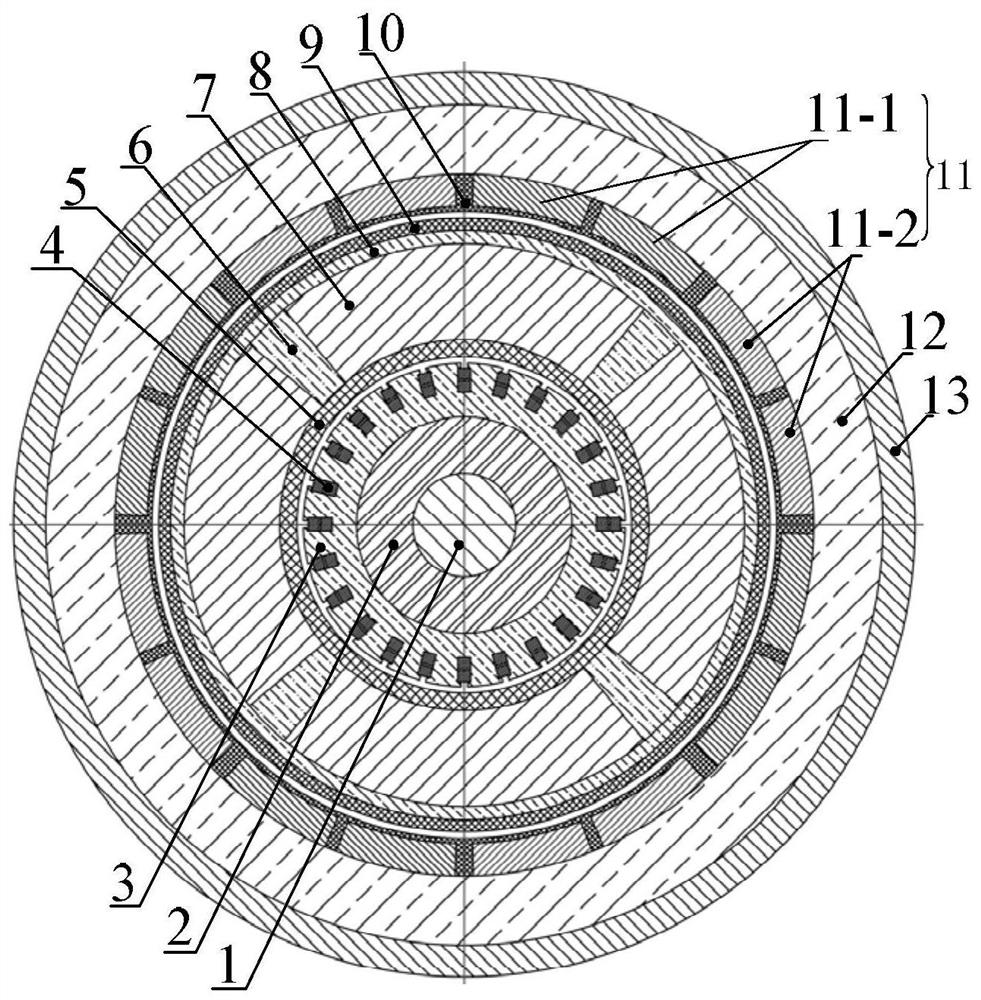

[0026] Specific implementation mode one: refer to figure 1 Specifically explain this embodiment, the radial coaxial integrated high power density inertial energy storage pulse power supply system described in this embodiment, the system includes an outer stator, an inner stator and a rotor,

[0027] The inner stator, rotor and outer stator are coaxially nested from the inside to the outside, there is an air gap between the inner stator and the rotor, and there is an air gap between the outer stator and the rotor;

[0028] The inner stator includes motor stator fixed shaft 1, motor stator back yoke 2, motor laminated stator core 3 and motor armature winding 4,

[0029] The rotor includes a carbon fiber support body 5 inside the rotor and a plurality of permanent magnets 7,

[0030] The motor stator back yoke 2 is fixed on the outer circumferential surface of the motor stator fixed shaft 1, and the outer circumferential surface of the motor stator back yoke 2 is covered with a ...

specific Embodiment approach 2

[0035] Specific embodiment 2: This embodiment is a further description of the radial coaxial integrated high power density inertial energy storage pulse power supply system described in specific embodiment 1. In this embodiment, the rotor also includes permanent magnet interpole fillers 6,

[0036] The space between two adjacent permanent magnets 7 is filled by permanent magnet interpole fillers 6 .

specific Embodiment approach 3

[0037] Embodiment 3: This embodiment is to further explain the radial coaxial integrated high power density inertial energy storage pulse power supply system described in Embodiment 1. In this embodiment, the rotor also includes a compensation cylinder 8 and an outer side of the rotor. carbon fiber strap 9,

[0038] Between the permanent magnet 7 and the carbon fiber support body 10 of the generator, a compensation cylinder 8 and a rotor outer carbon fiber strap 9 are arranged, and the rotor outer carbon fiber strap 9 is sleeved on the outer circumferential surface of the compensation cylinder 8 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com