Demetalization reactivation method of waste catalytic cracking catalyst

A catalytic cracking and demetallization technology, applied in catalytic cracking, catalyst regeneration/reactivation, physical/chemical process catalyst, etc., can solve the problems of complex process, limited application, and high cost of reactivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-9、 comparative example 1-2

[0045] (1) 10g spent catalytic cracking catalyst is put into crucible, according to the condition shown in table 1, roast in microwave muffle furnace;

[0046] (2) The product of step (1) is put into the container, and is processed with acid solution according to the conditions shown in Table 1;

[0047] (3) Cool the product of step (2) to room temperature, suction filter, wash with deionized water to neutrality (pH=7), and dry in a blast drying oven according to the conditions shown in Table 1 to obtain revived catalytic cracking catalyst.

[0048] (4) The Ni removal rate, V removal rate and micro-reaction activity of the revived catalytic cracking catalyst obtained were measured respectively, and the results are shown in Table 2.

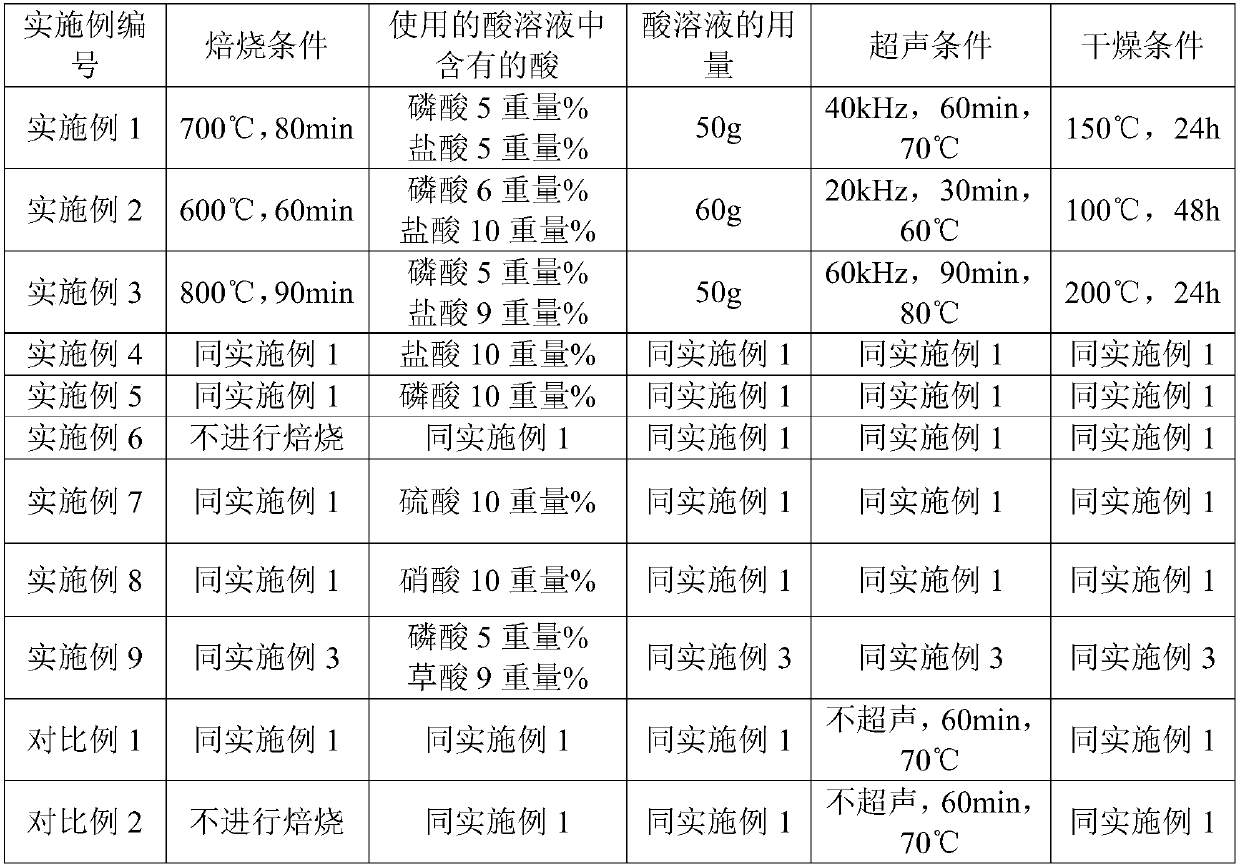

[0049] Table 1

[0050]

[0051] Table 2

[0052] Numbering Ni removal rate (%) V removal rate (%) Microreactive activity (%) Example 1 61 70 72 Example 2 66 75 75 Example 3 68 79 78 Example 4 56 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com