Intelligent and automatic spraying system and method for pressure-sensitive coating

An automatic spraying, pressure-sensitive coating technology, applied in spraying devices, manipulators, manufacturing tools, etc., can solve the problems of difficult to provide high-quality coating thickness, surface quality and coating uniformity control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

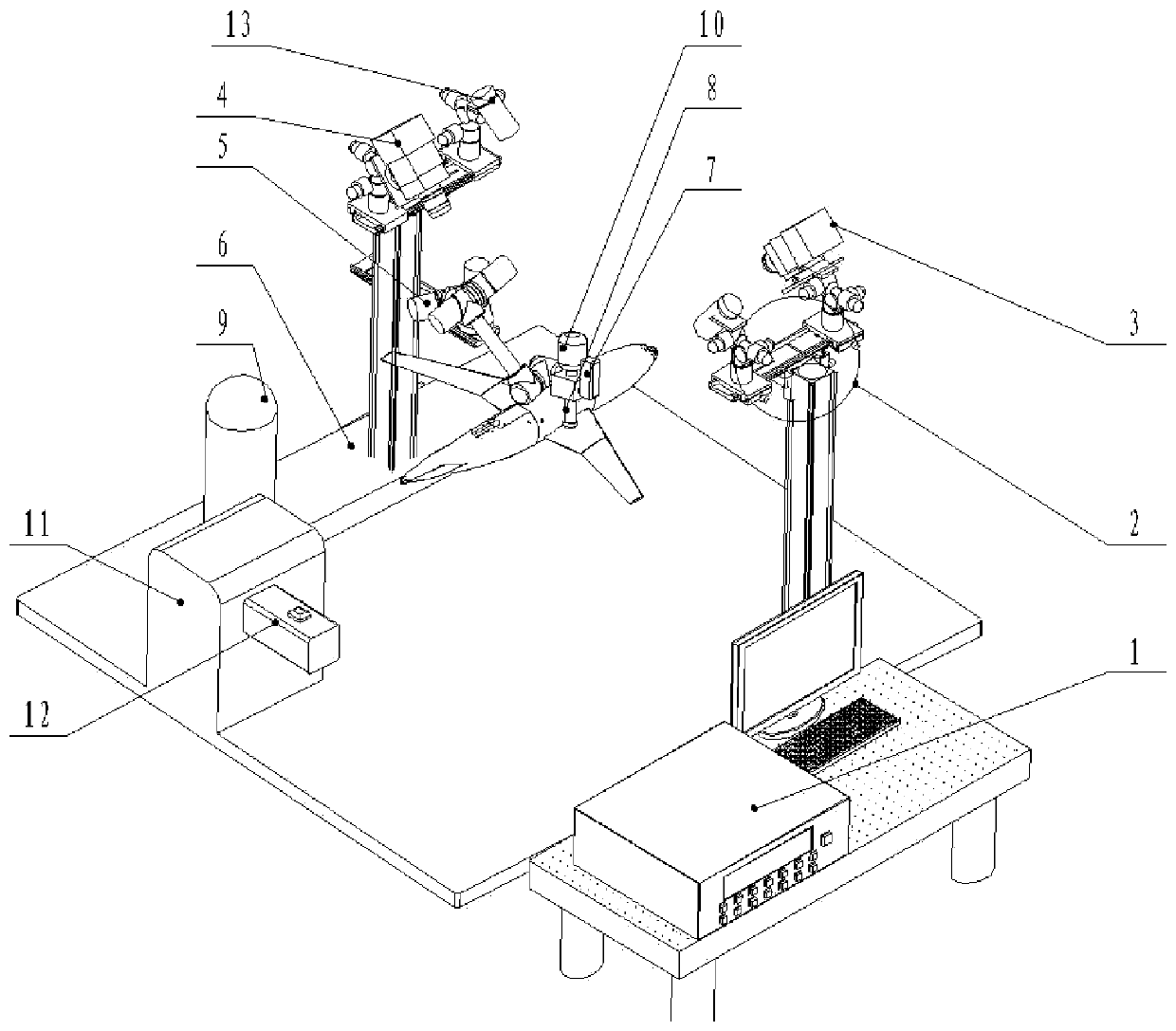

[0030] The specific implementation manner of the present invention will be described in detail in conjunction with the summary of the invention and the accompanying drawings.

[0031] An intelligent automatic spraying system for pressure-sensitive paint, which uses non-contact optical measurement technology to realize the recognition and acquisition of the three-dimensional contour of the model, and the intelligent control terminal 1 to design the spraying route, spraying device attitude, and flow rate, and output control signals to the model motion control Device 11, intelligent robot arm 5 and spraying device electromagnetic valve 7, wherein the model motion control device 11 controls the model rotation, the intelligent robot arm 5 drives the movement of the entire spraying device, and the spraying device electromagnetic valve 7 controls the spraying action and flow, and automatically completes the surface pressure of the model. Spraying of sensitive paints.

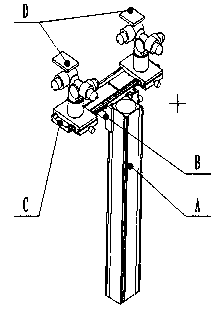

[0032] The spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com