Welding method of aero-engine exhaust casing

An aero-engine and welding method technology, which is applied to welding equipment, automatic control devices, metal processing mechanical parts, etc., can solve the problems of out-of-tolerance, large deformation, and low positioning accuracy of the exhaust casing, so as to save waste and loss costs, Improve welding efficiency and reasonable welding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings, but the claimed protection scope is not limited to the description.

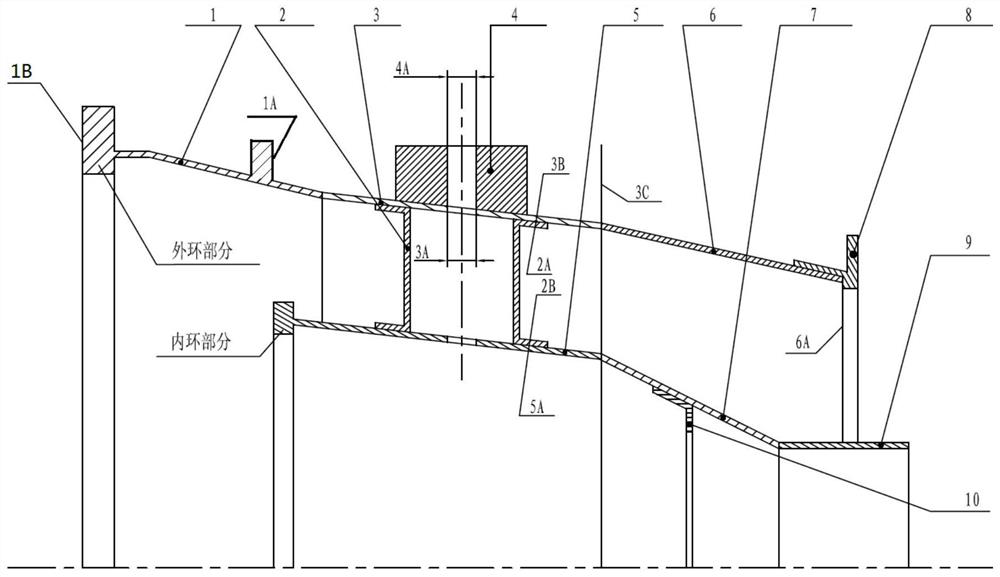

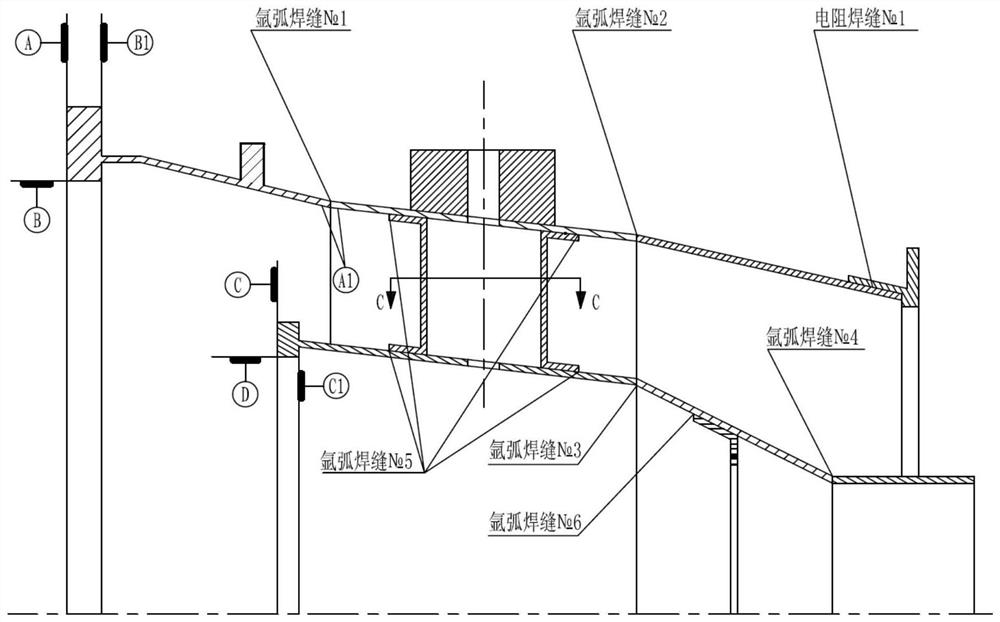

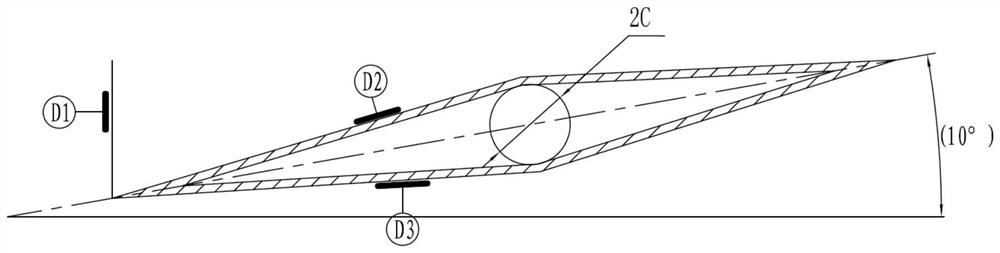

[0033] Such as figure 1 , the structure of the aero-engine exhaust casing is composed of an inner ring part, an outer ring part and a support plate. The front mounting edge 1 of the outer ring is connected to the front section 3 of the cylinder by argon arc welding, the rear section 6 of the cylinder is connected to the front section 3 of the cylinder by argon arc welding, and the rear section 6 of the cylinder is connected to the rear installation edge 8 of the outer ring through a resistor Welding connection; the inner ring mounting edge 5 of the inner ring part is connected with the center cone slope section 7 by argon arc welding, the center cone slope section 7 is connected with the exhaust pipe 9 by argon arc welding, and the center cone slope section 7 and the reinforci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com