Carbon dioxide deflagration pulse type pressurizing rock breaking device and process method

A rock-breaking device and carbon dioxide technology, applied in the direction of earthwork drilling, discharge machinery, etc., can solve the problems of safety and impact disturbance, and achieve the effects of high safety, less frequent replacement and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

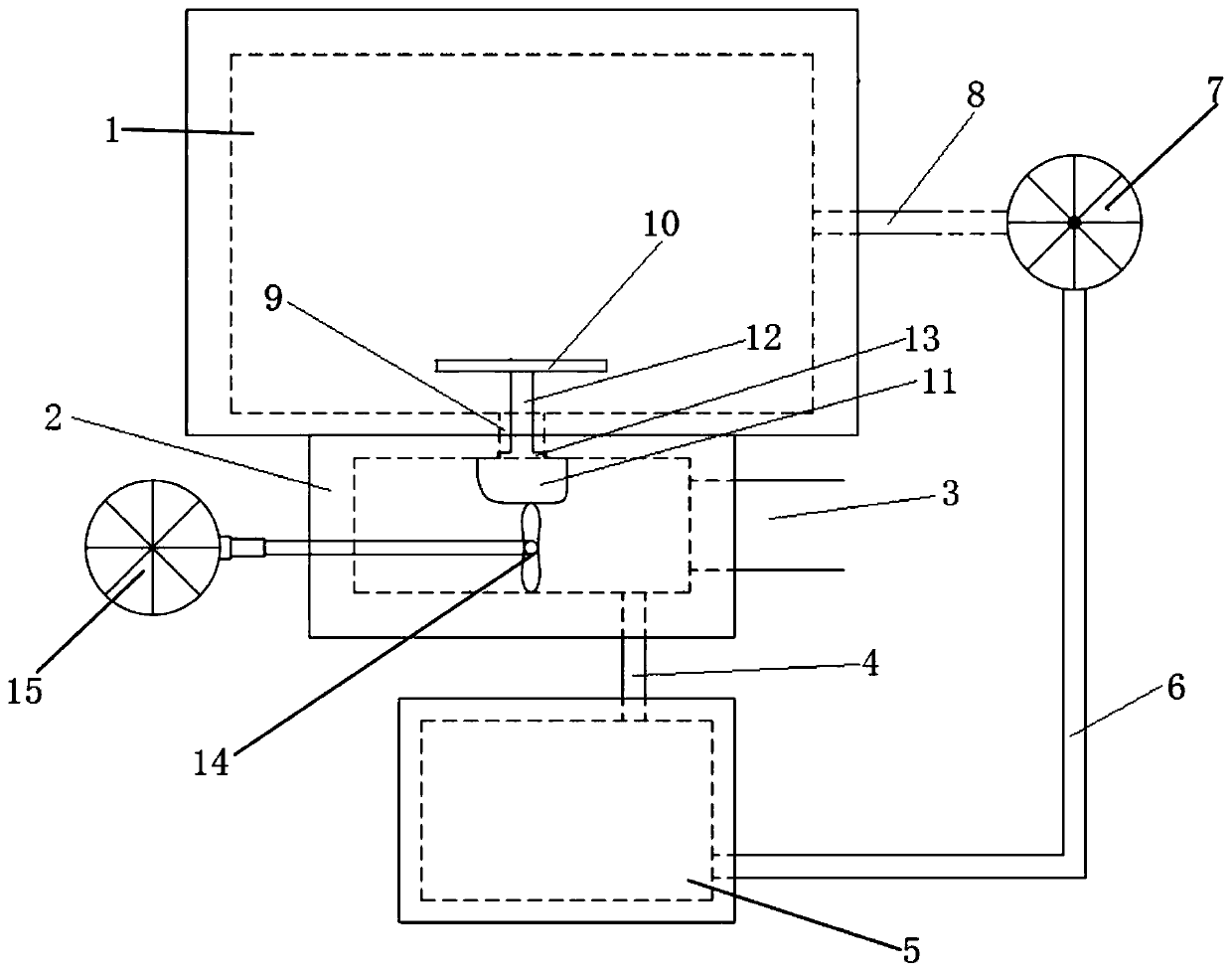

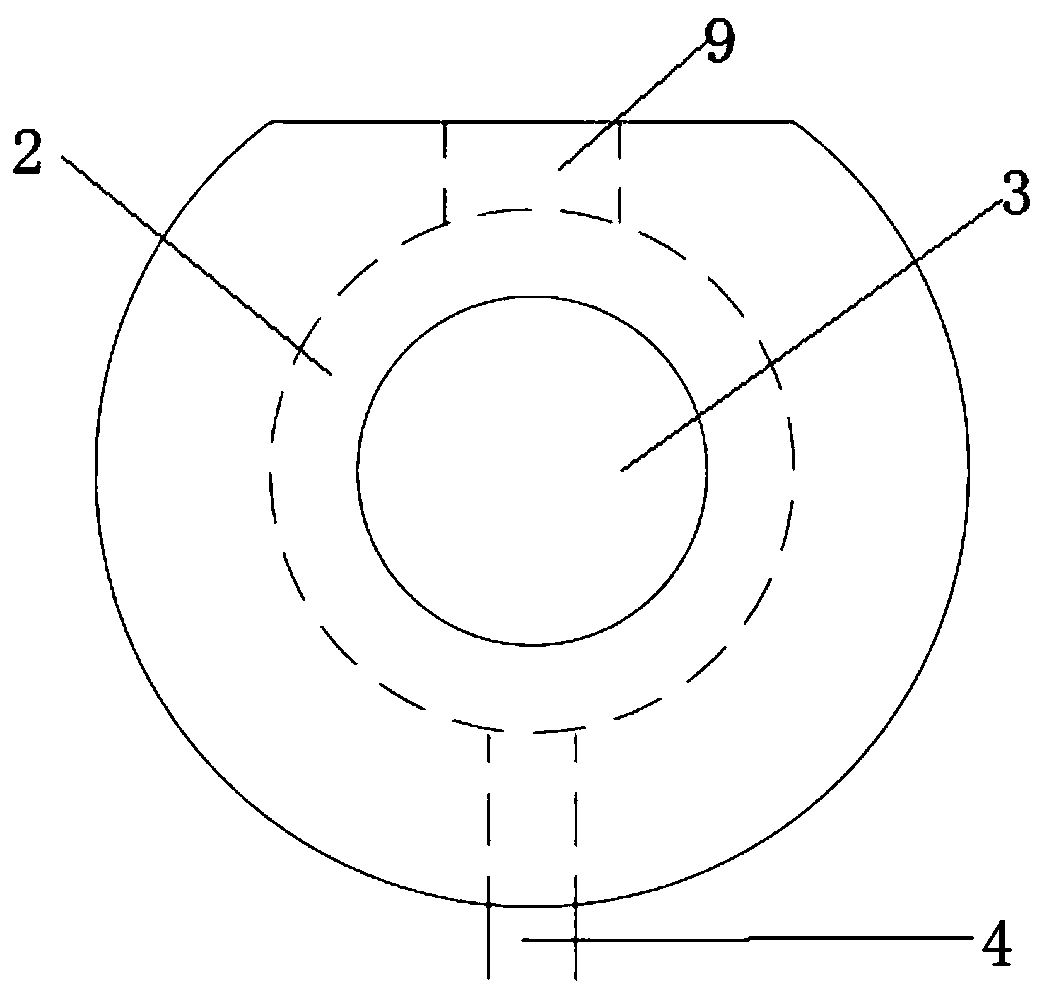

[0037] Such as figure 1 with figure 2 As shown, a carbon dioxide deflagration pulse pressurized rock breaking device includes a raw material storage bin 1 and a deflagration bin 2 arranged below the raw material storage bin 1; one end of the deflagration bin 2 is open and connected to a pressure-resistant Pipeline 3, the middle part of the deflagration chamber 2 is provided with an exhaust pipeline 4 and is connected to an exhaust device 5; the exhaust device 5 is connected to a high-pressure pump 7 through a pipeline one 6, and the high-pressure pump 7 is connected through a pipeline two 8 The raw material storage bin 1;

[0038] The bottom surface of the raw material storage bin 1 is tightly welded to the top surface of the deflagration bin 2, and is provided with a feed channel 9 that runs through the walls of the two bins; the raw material storage bin 1 is provided with a storage bin switch valve 10, the The lower end 11 of the switch valve 10 of the storage bin passes ...

Embodiment 2

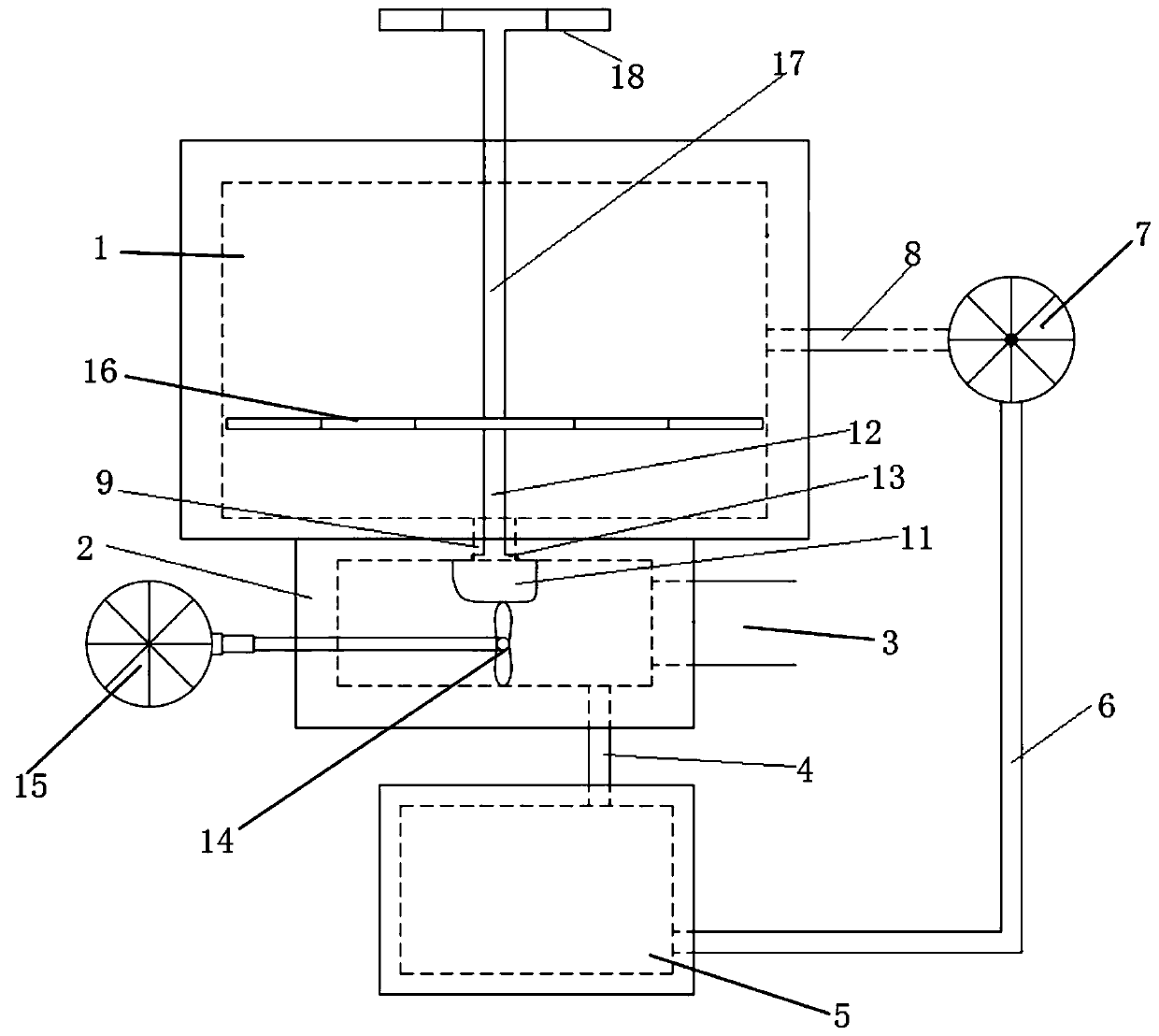

[0052] Such as image 3 with Figure 4 As shown, a carbon dioxide deflagration pulse pressurized rock breaking device includes a raw material storage bin 1 and a deflagration bin 2 arranged below the raw material storage bin 1; one end of the deflagration bin 2 is open and connected to a pressure-resistant Pipeline 3, the middle part of the deflagration chamber 2 is provided with an exhaust pipeline 4 and is connected to an exhaust device 5; the exhaust device 5 is connected to a high-pressure pump 7 through a pipeline one 6, and the high-pressure pump 7 is connected through a pipeline two 8 The raw material storage bin 1; the bottom surface of the raw material storage bin 1 is closely welded to the top surface of the deflagration bin 2, and a feed channel 9 is provided through the walls of the two bins;

[0053] The raw material storage bin 1 is also provided with a raw material grinding device; the raw material grinding device includes a file 16 arranged in the raw material...

Embodiment 3

[0058] A carbon dioxide deflagration pulse pressurized rock breaking process method, comprising the carbon dioxide deflagration pulse pressurized rock breaking device in embodiment 1 or embodiment 2, the process method includes the following steps:

[0059] Step 1: adding deflagration raw materials into the raw material storage bin and grinding them into powder;

[0060] Step 2: Control the motor to rotate the impeller to open the on-off valve of the storage bin, press the powdery deflagration raw material into the deflagration bin; close the on-off valve of the storage bin;

[0061] Step 3: Initiate the deflagration and stamping of the deflagration raw material through the ignition device, and the transient high-pressure gas generated flows into the blasted place through the pressure-resistant pipeline to realize the first fracturing;

[0062] Step 4: Open the exhaust device to discharge the residual gas after deflagration, and the residual gas is passed into the raw material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com