Bran feeding device for suspension furnace

A suspension furnace and bran feeding technology, which is applied in the direction of drying solid materials, lighting and heating equipment, dry cargo handling, etc., can solve the problems of system paralysis, affecting the normal operation of fan equipment, and entering the fan, so as to achieve safe and reliable use and avoid internal The effect of overheating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

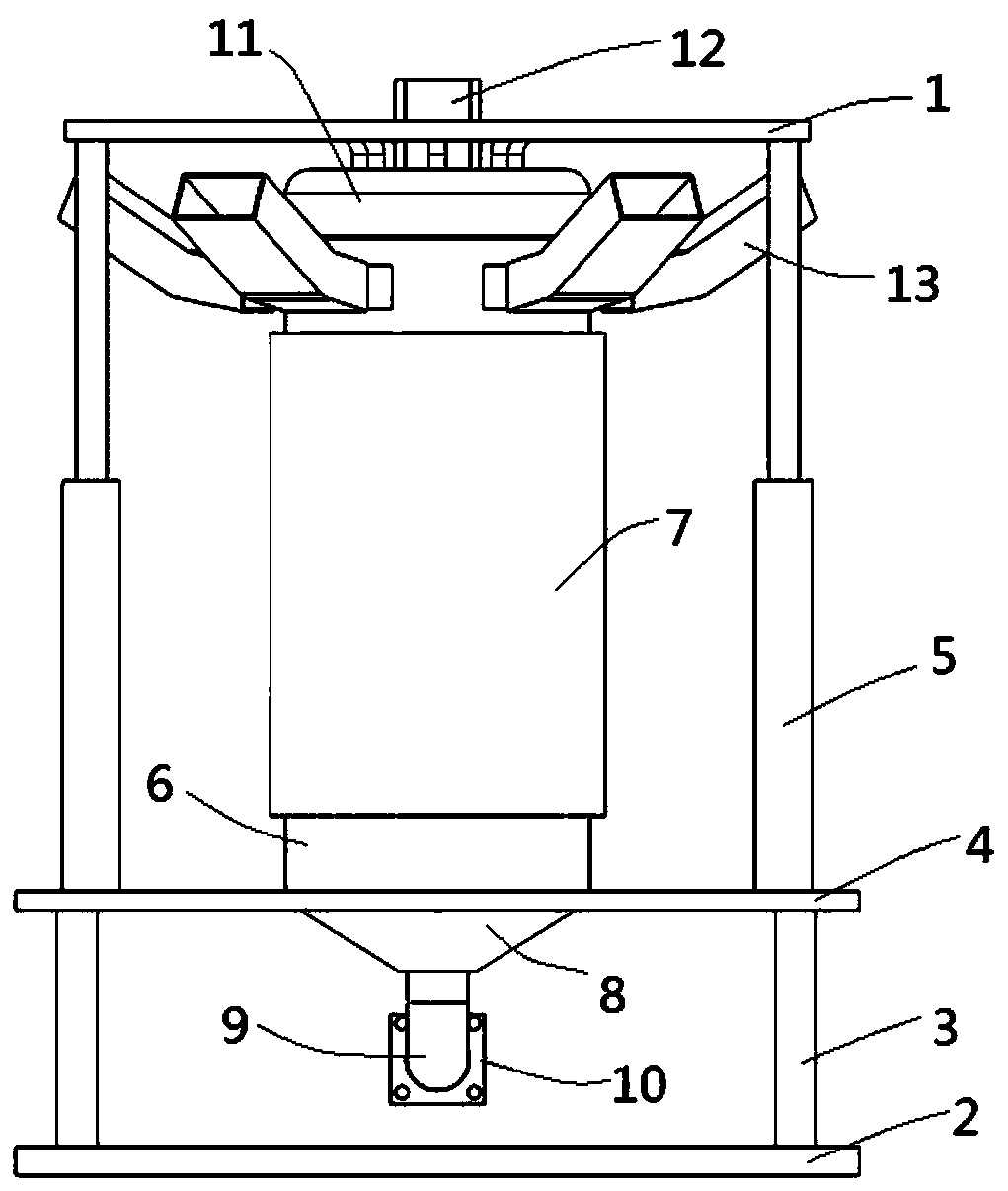

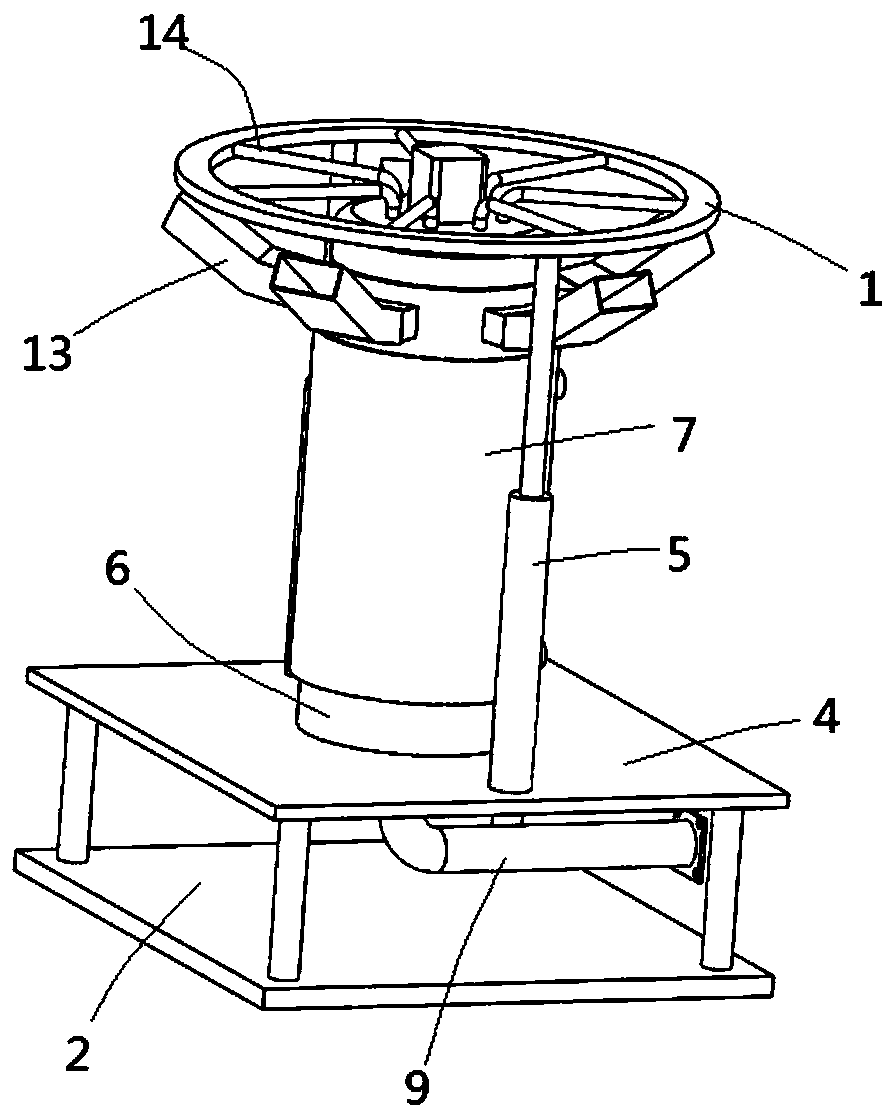

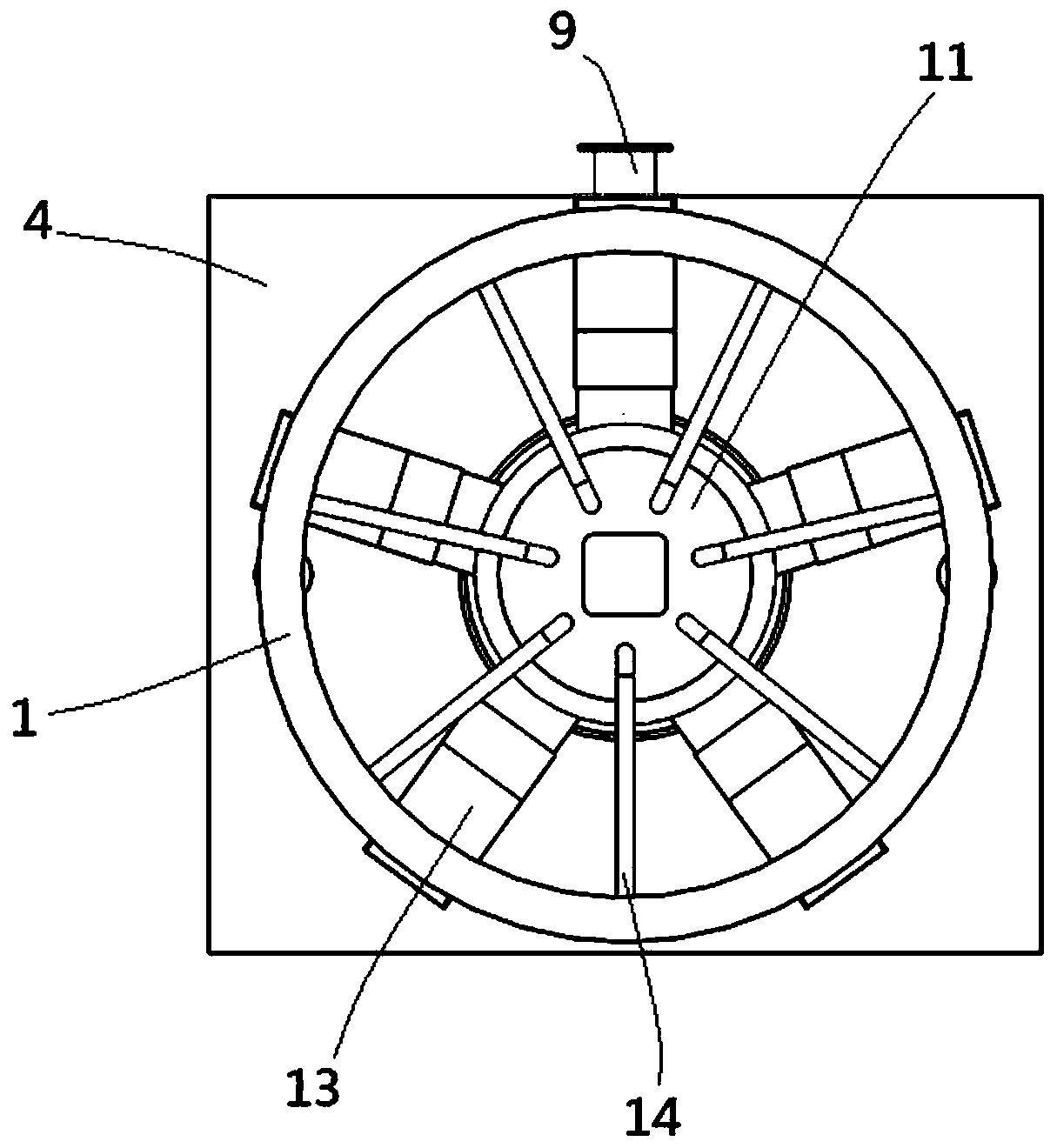

[0026] Example 1: see Figure 1-5 , a device for feeding bran into a suspension furnace, comprising an annular plate 1, a bottom plate 2, a support column 3, and a mounting plate 4, the top of the bottom plate 2 is fixed with a mounting plate 4 through several support columns 3, and the middle part of the mounting plate 4 A through hole is provided, and the lower port of the through hole is fixed with a tapered cylindrical discharge hopper 8 , the discharge port of the discharge hopper 8 is connected with a connecting pipe 9 , and the end of the connecting pipe 9 is connected with a connecting flange 10 .

[0027] The upper port of the through hole on the mounting plate 4 is connected with the material storage cylinder 6 communicating with it, and the top of the side wall of the material storage cylinder 6 is distributed with feed holes, and each feed hole is connected with a feed pipe 13, so The top end of the material storage tube 6 is open, and is provided with a top cover ...

Embodiment 2

[0033] Embodiment 2: In this embodiment, the chaff feeding device of the suspension furnace includes an annular plate 1, a bottom plate 2, a support column 3, and a mounting plate 4. The top of the bottom plate 2 is fixed with a mounting plate 4 through several support columns 3. The middle part of the mounting plate 4 is provided with a through hole, and the lower port of the through hole is fixed with a tapered cylindrical discharge hopper 8, the discharge port of the discharge hopper 8 is connected with a connecting pipe 9, and the end of the connecting pipe 9 is connected to There are connecting flanges 10 .

[0034] The upper port of the through hole on the mounting plate 4 is connected with the material storage cylinder 6 communicating with it, and the top of the side wall of the material storage cylinder 6 is distributed with feed holes, and each feed hole is connected with a feed pipe 13, so The top end of the material storage tube 6 is open, and is provided with a top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com