Rapid silicon transfer detection method of silicon-containing release film

A detection method and release film technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of unfriendly environment, long test time, long time, etc., and achieve good reference significance and stable and reliable test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

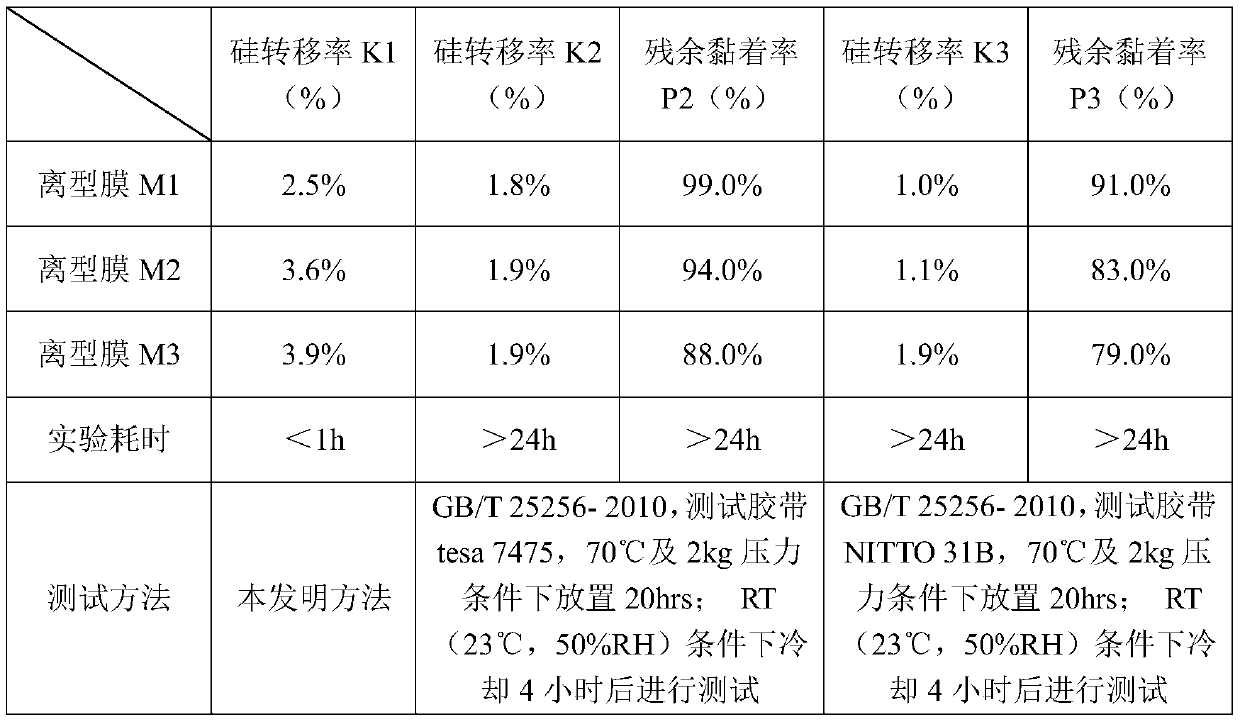

Examples

Embodiment 1

[0021] The detection steps of this embodiment are as follows:

[0022] In step a, take a sample of the silicon-containing release film to be tested in the size of A4 paper, cut it into a circular sample with a diameter of about 3.6 cm, and use a LAB-X5000 desktop X-ray fluorescence spectrometer to test its silicon coating amount A;

[0023] Step b, take a clean A4-sized PET original film and cut it into a size of 10×25cm for later use;

[0024] Step c, weigh the purchased modified acrylic AB glue according to the ratio and mix it evenly, apply it to the release surface of the release film sample with a scraper, and quickly cover it with the original PET film within 1 minute, and then Stand for 6 minutes under a 2KG pressure strip, and tear off the PET film with glue after the glue is cured to obtain a treated release film sample;

[0025] In step d, the treated release film sample is tested by an X-ray fluorescence spectrometer to obtain the silicon coating amount B;

[0026...

Embodiment 2

[0028] In step a, prepare an A4-sized silicon-containing release film and an A4-sized PET original film. The PET original film can be a conventional transparent PET original film with a thickness of 50 μm. Cut the silicon-containing release film sample into a circular sample with a diameter of about 3.6 cm, and use a LAB-X5000 desktop X-ray fluorescence spectrometer to test its silicon coating amount A;

[0029] In step b, the test glue is commercially available modified acrylate AB glue DY-J39, which is ready for use.

[0030] Step c, place the release film sample on a flat polytetrafluoroethylene plate, weigh and mix the modified acrylate AB glue DY-J39 according to the ratio of 1:1, and apply it on the release surface with a scraper Be sure to completely cover the silicon-containing surface;

[0031] Then quickly cover the original PET film within 1 minute, and then stand it under a 5KG bead for 6-8 minutes. After the glue is cured, tear off the PET film with glue to obtai...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com