Giant rice centrifugal cleaning funnel sieve device and harvester

A technology of harvester and funnel, which is applied in the research field of harvester, can solve the problems such as difficult cleaning of the extracted mixture, thick stems, etc., and achieve the effects of simple structure, improved cleaning rate, and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

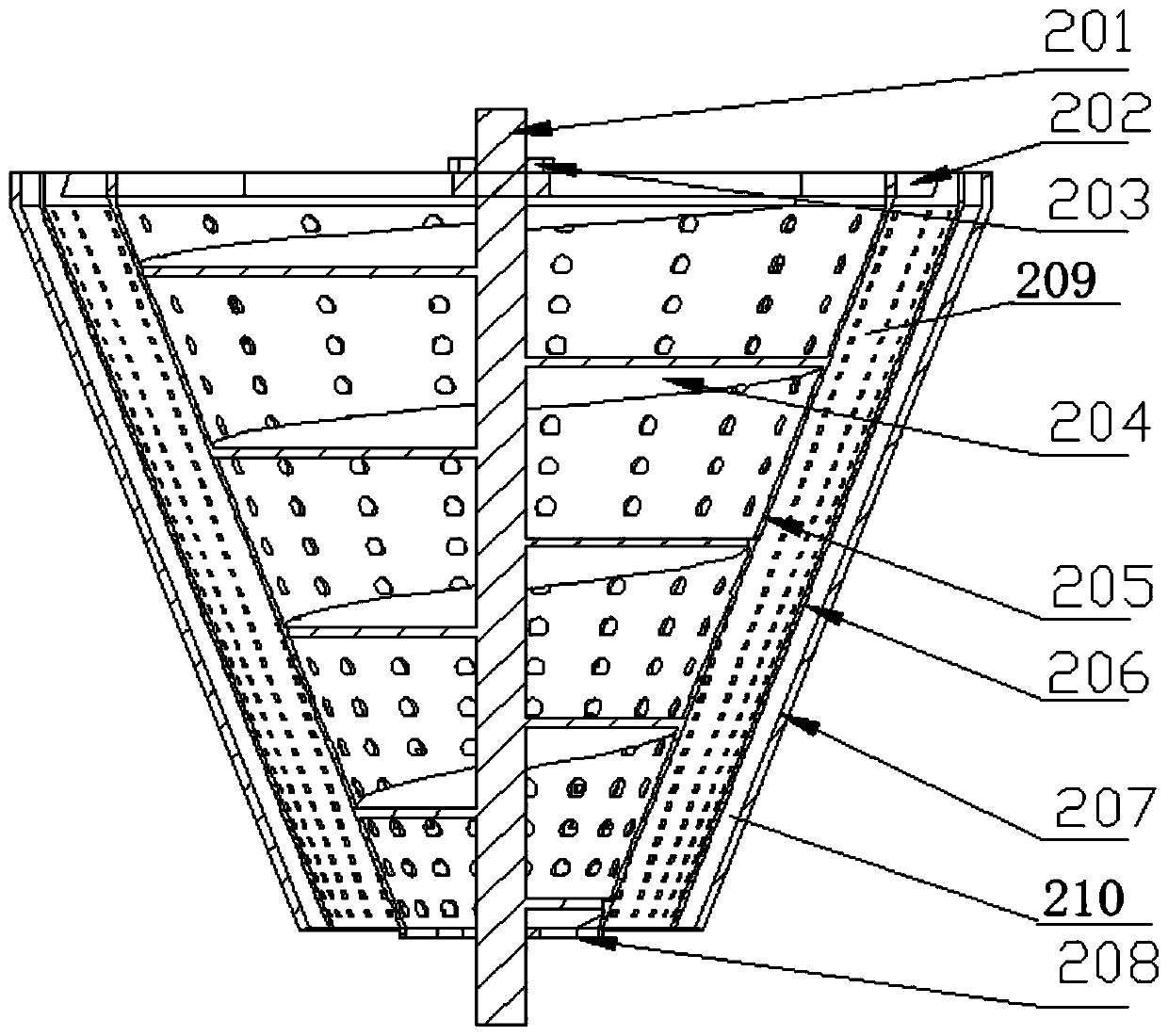

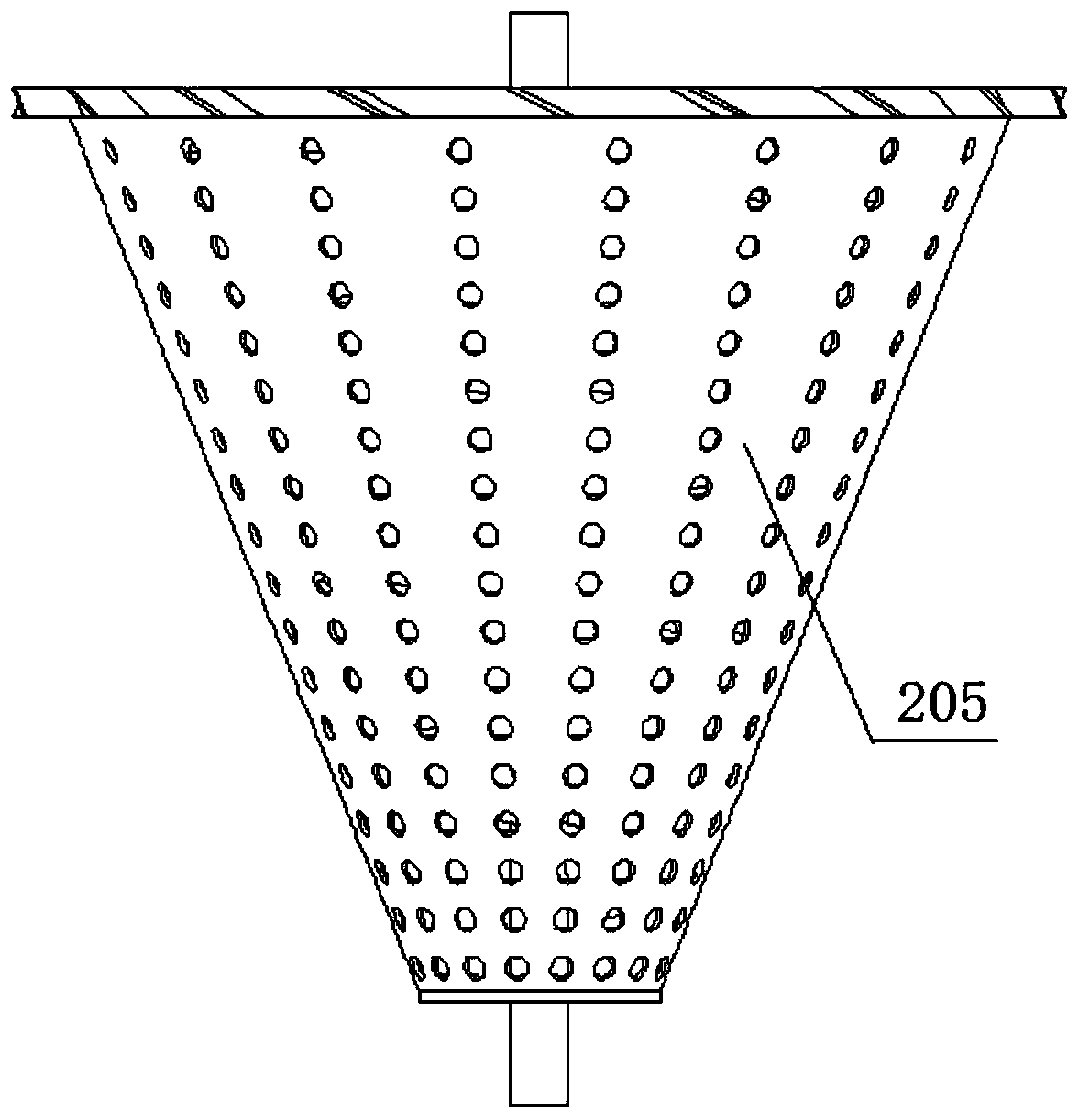

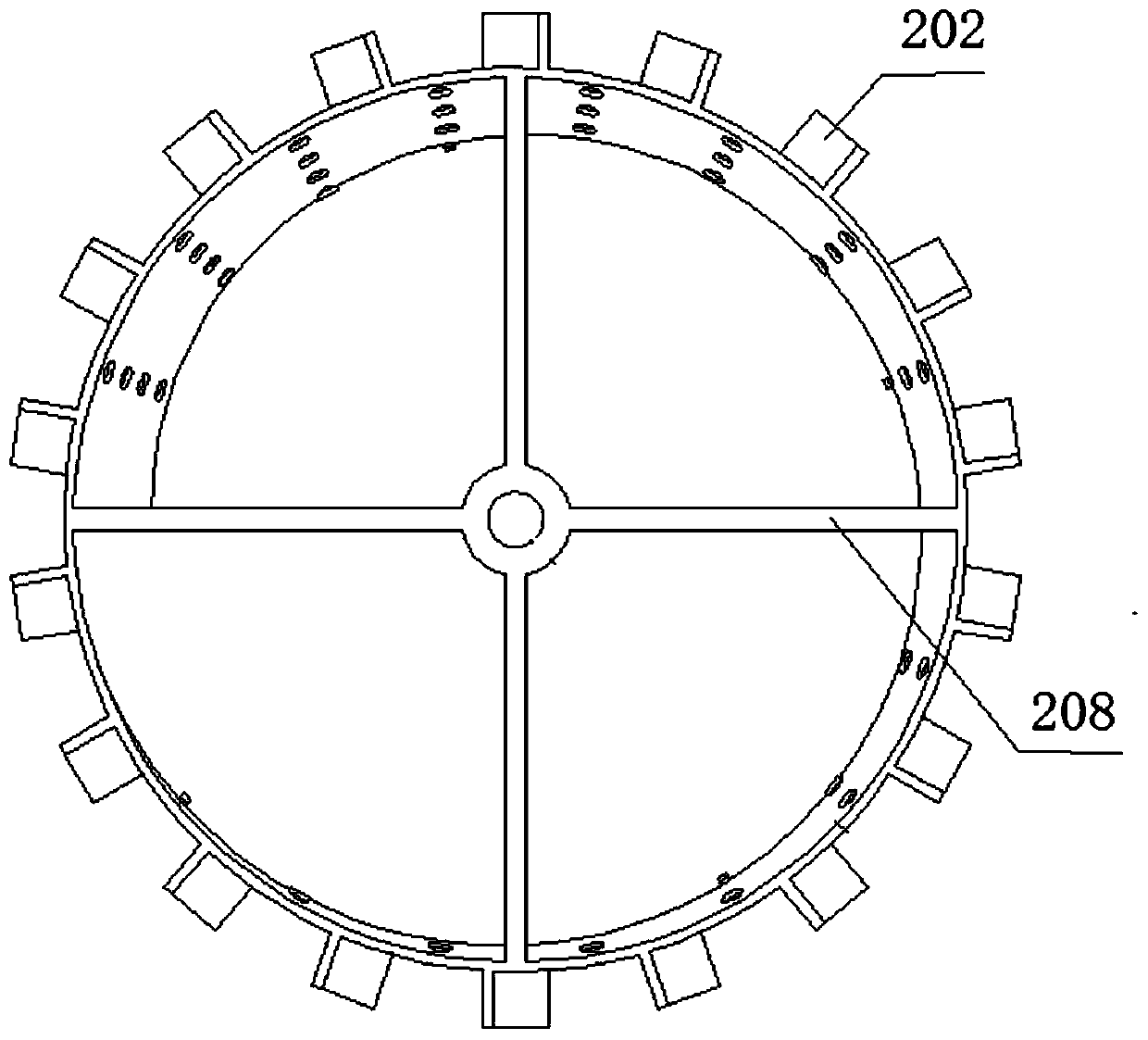

[0034] figure 1 The description is a preferred embodiment of the giant rice centrifugal cleaning funnel screen device of the present invention, and the giant rice centrifugal cleaning funnel screen device includes a centrifugal cleaning funnel screen 2 . The centrifugal cleaning funnel screen 2 includes a main shaft 201, blades 202, spiral deflectors 204, a centrifugal cylinder body 205, a funnel screen 206 and an outer casing 207; the main shaft 201 runs through the entrance and the bottom of the centrifugal cylinder body 205 top The outlet of the main shaft 201 is provided with a spiral deflector 204 such as Figure 5 As shown, the spiral deflector 204 has a shape that is wide at the top and narrow at the bottom, extending from the inlet at the top of the centrifugal cylinder body 205 to the outlet at the bottom; wall connection; the cylinder wall of the centrifuge cylinder body 205 is provided with a plurality of through holes, such as figure 2 As shown; the centrifugal ...

Embodiment 2

[0044] Figure 9 Shown is a kind of preferred embodiment of the harvester of the present invention, described harvester comprises the giant rice centrifugal cleaning funnel sieve device described in embodiment 1, therefore has the beneficial effect of embodiment 1, no longer here repeat.

[0045] The harvester includes at least two vertical side-by-side centrifugal cleaning funnel screens 2; each of the centrifugal cleaning funnel screens 2 is provided with a funnel 1; the funnel 1 is installed in the harvester threshing The lower part of the device covers the falling range of the escape mixture. The residual discharge pipeline 3 is connected to the bottom of the funnel screen 206, and the residual discharge pipeline 3 is L-shaped, and is used to extend to the side of the machine to discharge the residual.

[0046] Below the centrifugal cleaning funnel sieve 2 is provided with a grain delivery auger 4, which collects the grains falling from the grain discharge channel 210 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com