Ceramic cylindrical roller penetrating type centerless grinding machining method and device

A cylindrical roller and centerless grinding technology, which is applied in the direction of grinding drive device, grinding/polishing safety device, abrasive surface adjustment device, etc., can solve the problem that it is difficult to meet the requirements of high efficiency and high precision processing of cylindrical roller, grinding wheel, Problems such as low trimming accuracy of the guide wheel and reduced processing efficiency can achieve the effects of improving processing efficiency and processing accuracy, stable contact friction coefficient, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

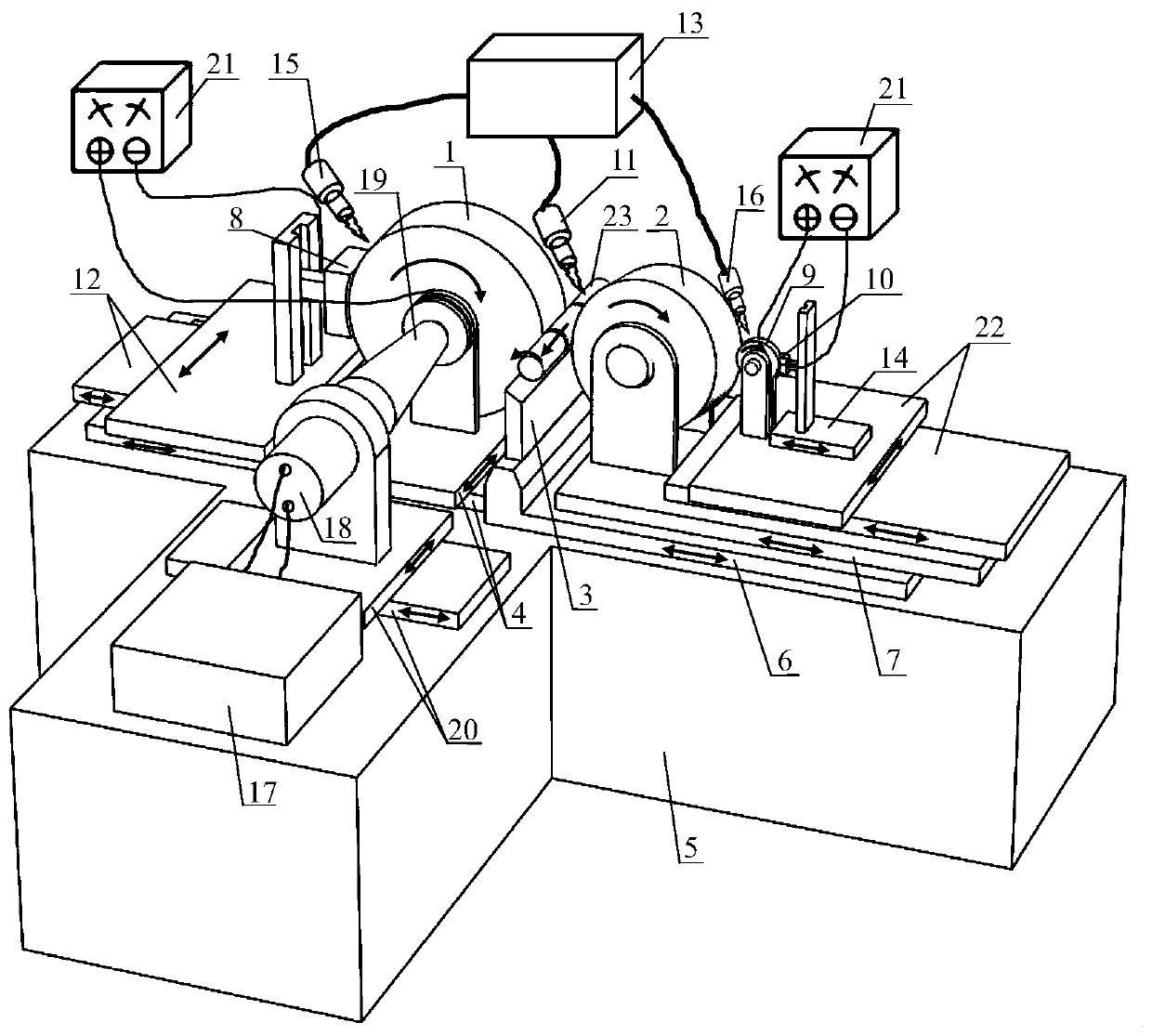

[0021] The ceramic cylindrical roller through-type centerless grinding processing method of the present invention can be realized by the ceramic cylindrical roller through-type centerless grinding processing device of the present invention. The ceramic cylindrical roller through-type centerless grinding device of the present invention can be obtained by modifying the existing through-type centerless grinding machine.

[0022] see figure 1 , as a specific embodiment: the ceramic cylindrical roller penetrating centerless grinding device of the present invention includes a grinding wheel 1, a guide wheel 2, and a supporting plate 3 arranged between the grinding wheel 1 and the guide wheel 2; The guide wheel 2 is set at an angle of inclination relative to the grinding wheel 1; the grinding wheel 1 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com