Brick antique finishing device

An old equipment and bricklaying technology, which is applied in the field of bricklaying and old equipment, can solve the problems of time-consuming manual adjustment and single effect, and achieve the effect of high transmission precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments will be described in detail with reference to the accompanying drawings.

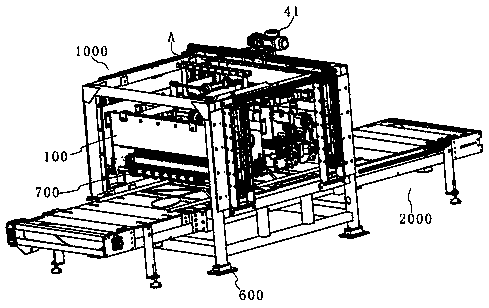

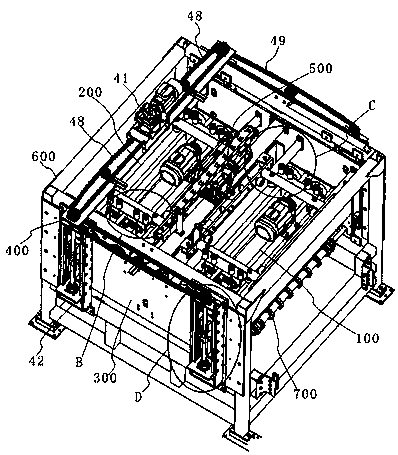

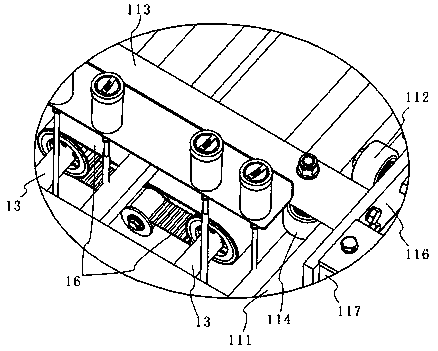

[0049] Such as Figure 1-18 As shown, the present embodiment provides a kind of old bricklaying equipment, including a old main machine 1000 and a conveyor 2000 for transferring workpieces. The old main machine 1000 includes an old outer frame 600 erected above the conveyor 2000 and The old assembly A100, the old assembly B200 and the lifting drive mechanism 400 installed on the old outer frame 600, the function of the conveyor 2000 is to undertake and transport the brickwork from front to back, which can use a conventional conveyor The structure will not be described in detail here, but the function of the old-fashioned host 1000 is to chisel and make old the upper surface of the brickwork on the conveying surface of the conveyor 2000, thereby producing di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com