Municipal well lid maintenance device

A technology for maintaining devices and manhole covers, which is applied in hoisting devices, hoisting devices, liquid separation agents, etc., can solve the problems of large quality and volume, short time consumption, low utilization rate, etc., achieve high automation, improve efficiency, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing:

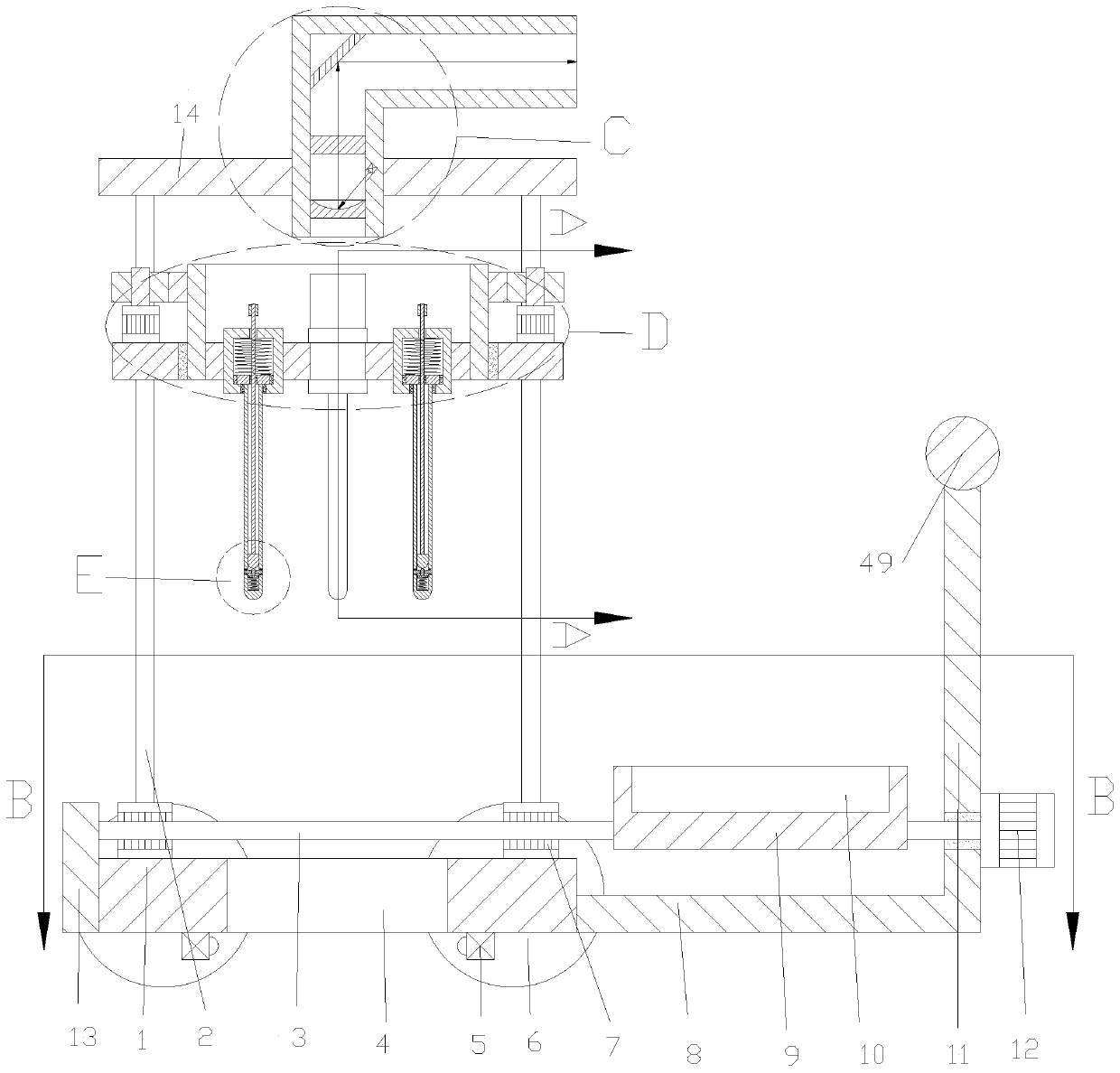

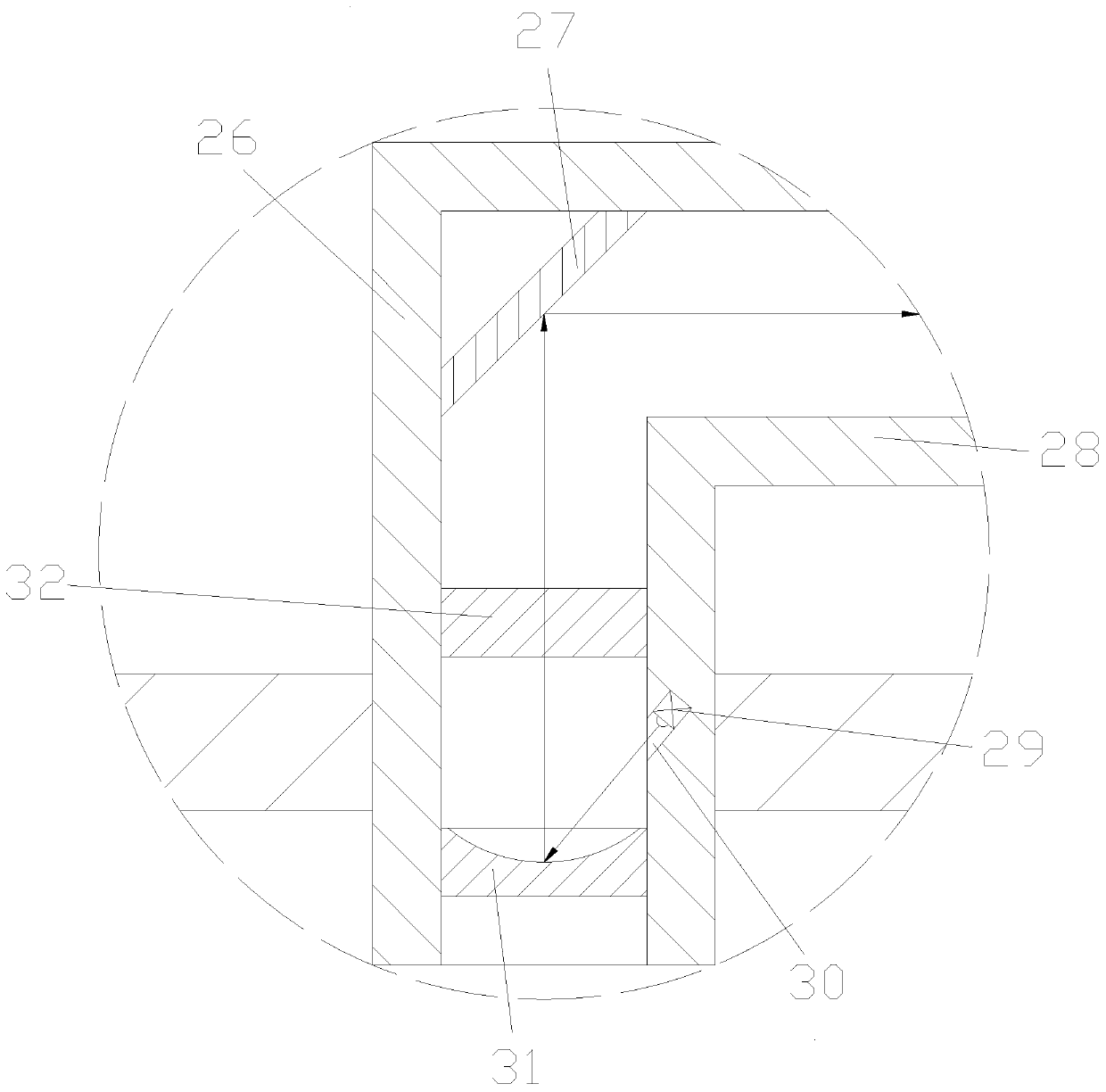

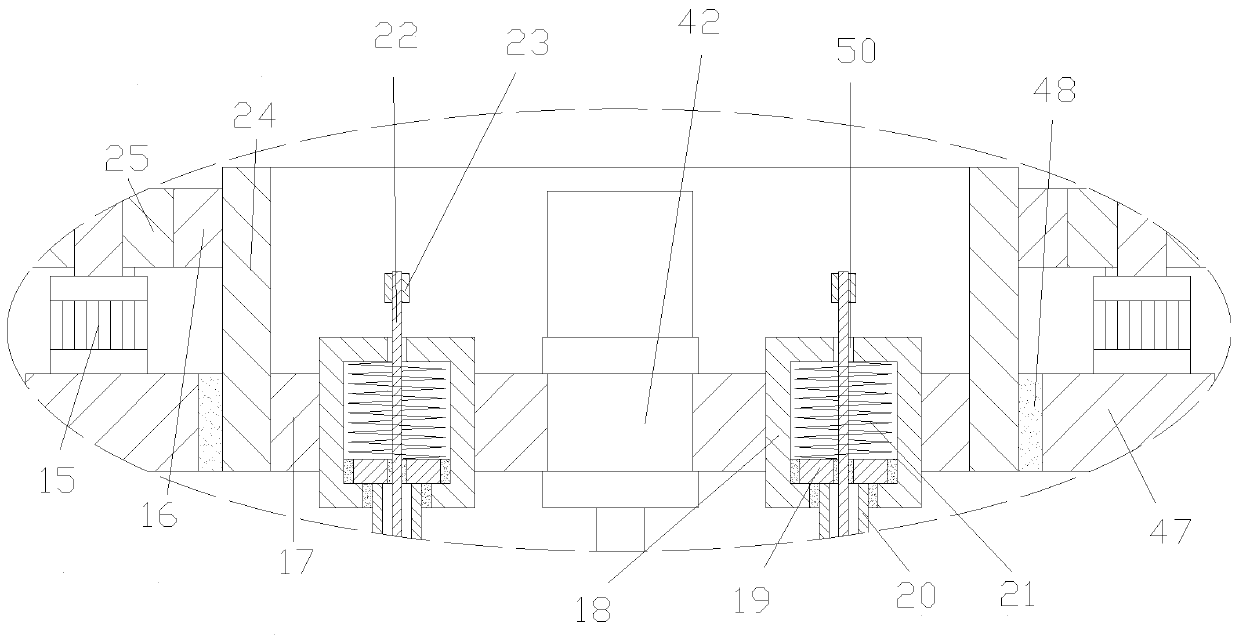

[0019] Refer to attached figure 1 , 2 , 3, 4: This municipal well cover maintenance device includes a lifting mechanism and an aiming mechanism, an aiming mechanism is arranged above the lifting mechanism, and the lifting mechanism includes a motor one 7, and a top plate 14 is arranged above the motor one 7, The top of the motor-7 is equipped with a leading screw-2 that is rotatably connected to the top plate 14, and a sliding plate-47 is slidably connected between the leading screw-2, and the center of the sliding plate-47 is provided with a circular channel 48. The inner wall of the circular channel 48 is rotatably connected with a sleeve 24 whose top and bottom communicate with the outside world. The upper half of the sleeve 24 is located above the sliding plate one 47, and the bottom of the sleeve 24 is flush with the bottom of the sliding plate one 47. The inner wall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com