DCS based three-stage wastewater pH control method and system

A control method and technology for wastewater, which are applied in water treatment parameter control, comprehensive factory control, chemical instruments and methods, etc., can solve the problems of pH value overshoot, no protection adjustment tank, and inability to pull the wastewater pH back to the target value, etc. Achieve the effect of reducing hysteresis and reducing pH fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

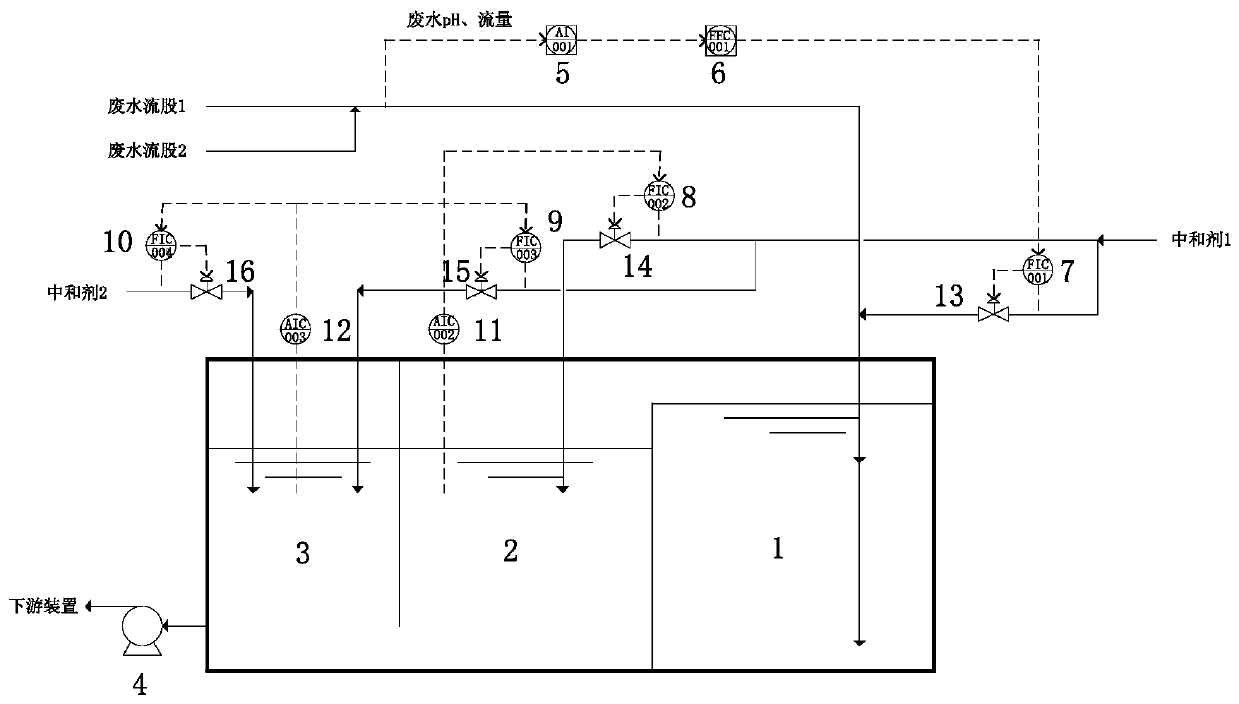

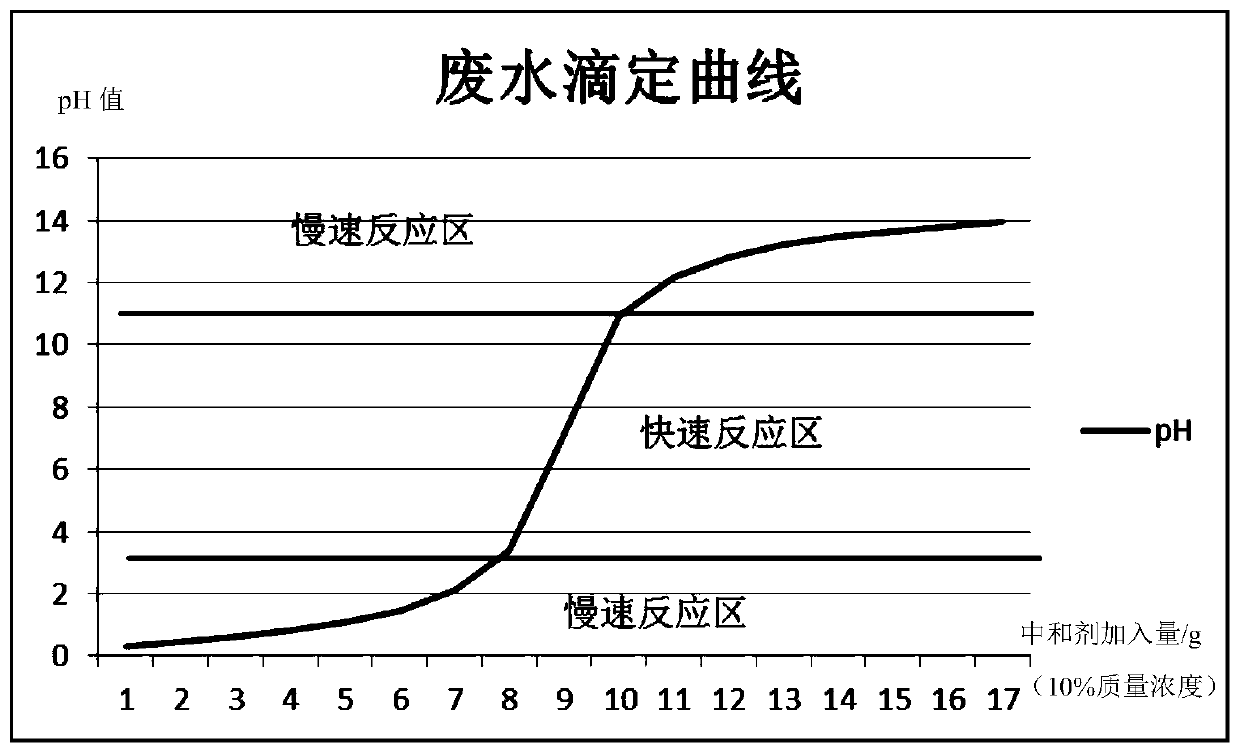

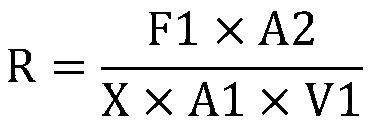

[0079] A chemical plant produces a stream of alkaline wastewater with a pH value between 10 and 12. 8% hydrochloric acid is used as a neutralizing agent to adjust the pH in a three-stage neutralization tank. It is hoped that the pH value will be controlled at 5 to 7. In addition to this stream of wastewater, this wastewater pool also regularly receives another stream of alkaline wastewater with a pH value above 13 (2-3 times per shift), which causes large fluctuations in the flow and composition of wastewater entering the neutralization tank. The designed simple circuit cannot realize the stable control of the pH value, requiring frequent manual intervention by the operator, the operation volume is as high as 15 times per shift, and the pH overshoots by more than ±3, which not only hinders the long-term stable operation of the wastewater treatment system, but also seriously affects The degree of automation of the device. For this reason, carry out transformation according to t...

Embodiment 2

[0095] A chemical plant produces a stream of acidic wastewater with a pH value between 3 and 4. Use 10% caustic soda as a neutralizing agent to adjust the pH in the neutralization tank. It is hoped that the pH value will be controlled at 6 to 8, because there is only one level of neutralization The mixing time of acidic wastewater and caustic soda is short, and the neutralization is incomplete. Therefore, the pH value of the wastewater at the outlet of the neutralization tank can only be controlled at (6-10), which affects the service life of downstream devices. For this reason, according to this patent, carry out transformation, enlarge it into a three-level protection pool, and add 10% caustic soda pipeline in the fine adjustment pool, and add 10% caustic soda pipeline and 10% hydrochloric acid pipeline in the protection pool, and control in DCS according to the design of this patent The program is reconfigured.

[0096] After transformation, the alkaline waste water first e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com