A kind of preparation method of conductive geopolymer

A geopolymer and mixture technology, applied in cement production and other directions, can solve the problems of poor electrothermal performance and expensive conductive materials, and achieve the effects of good electrical conductivity, low energy consumption and broad prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

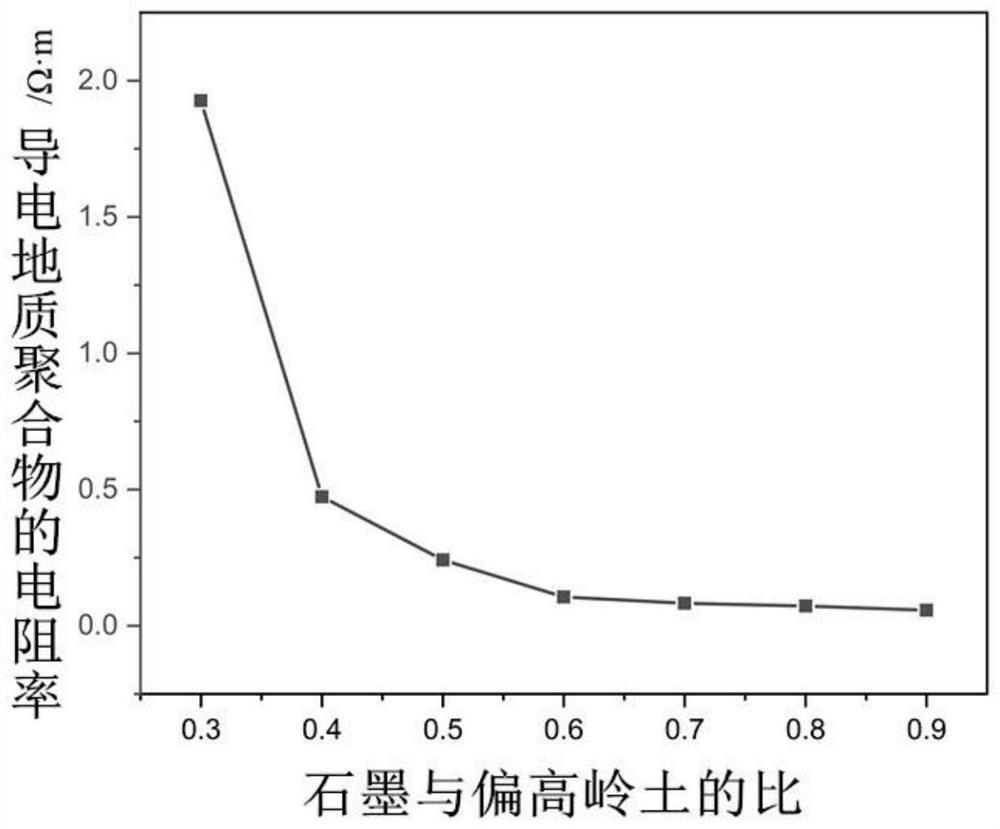

Embodiment 1

[0022] A preparation method of conductive geopolymer, the operation steps are as follows:

[0023] (1) According to graphite and metakaolin mass ratio is 0.2:1, metakaolin and graphite are mixed, adopt horizontal chemical industry stirrer to fully stir, obtain mixture;

[0024] (2) add phosphoric acid, distilled water successively in the mixture gained in step (1), the mass ratio of phosphoric acid and metakaolin is 0.8:1, add distilled water, make solid-liquid ratio be 0.65, described solid-liquid ratio is graphite and metakaolin Quality: the quality of distilled water and phosphoric acid, stirring quickly, mixing reaction, phosphoric acid and metakaolin react at this time, stop stirring when the mixture is thick and uniform; among them, distilled water is used as both a solvent and a catalyst;

[0025] (3) Put the material obtained after the reaction in step (2) into a fixed mold, oscillate to make the material packed tightly, and eliminate the interference of air bubbles, t...

Embodiment 2

[0027] A preparation method of conductive geopolymer, the operation steps are as follows:

[0028] (1) According to graphite and metakaolin mass ratio is 0.4:1, metakaolin and graphite are mixed, adopt horizontal chemical industry stirrer to fully stir, obtain mixture;

[0029] (2) add phosphoric acid, distilled water successively in step (1) gained mixture, the mass ratio of phosphoric acid and metakaolin is 0.6:1, add distilled water, make solid-liquid ratio be 0.7, described solid-liquid ratio is graphite and metakaolin Quality: the quality of distilled water and phosphoric acid, stirring quickly, mixing reaction, phosphoric acid and metakaolin react at this time, stop stirring when the mixture is thick and uniform; among them, distilled water is used as both a solvent and a catalyst;

[0030] (3) Put the material obtained after the reaction in step (2) into a fixed mold, oscillate to make the material packed tightly, and eliminate the interference of air bubbles, then put ...

Embodiment 3

[0032] A preparation method of conductive geopolymer, the operation steps are as follows:

[0033] (1) According to graphite and metakaolin mass ratio is 0.6:1, metakaolin and graphite are mixed, adopt horizontal chemical industry stirrer to fully stir, obtain mixture;

[0034] (2) add phosphoric acid, distilled water successively in the mixture gained in step (1), the mass ratio of phosphoric acid and metakaolin is 0.7:1, add distilled water, make solid-liquid ratio be 0.8, described solid-liquid ratio is graphite and metakaolin Quality: the quality of distilled water and phosphoric acid, stirring quickly, mixing reaction, phosphoric acid and metakaolin react at this time, stop stirring when the mixture is thick and uniform; among them, distilled water is used as both a solvent and a catalyst;

[0035] (3) Put the substance obtained after the reaction in step (2) into a fixed mold, shake to make the substance packed tightly, and eliminate the interference of air bubbles, then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com