A road crack filling machine

A seam filling machine and road technology, applied in the field of road repair, can solve problems such as property loss, time-consuming and labor-intensive repair process, narrow, long and winding road cracks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

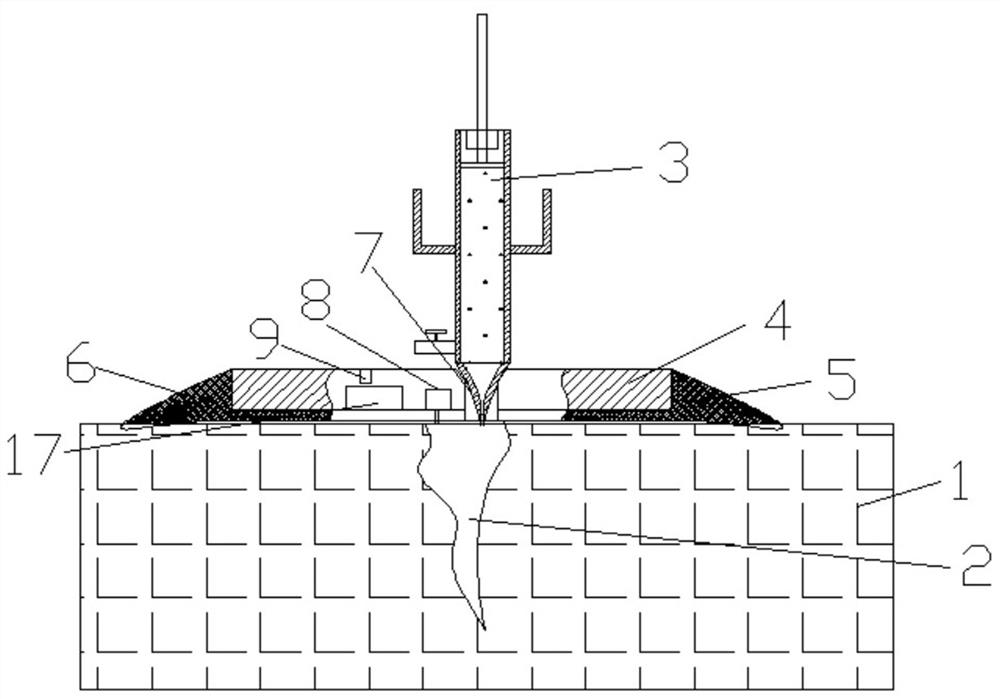

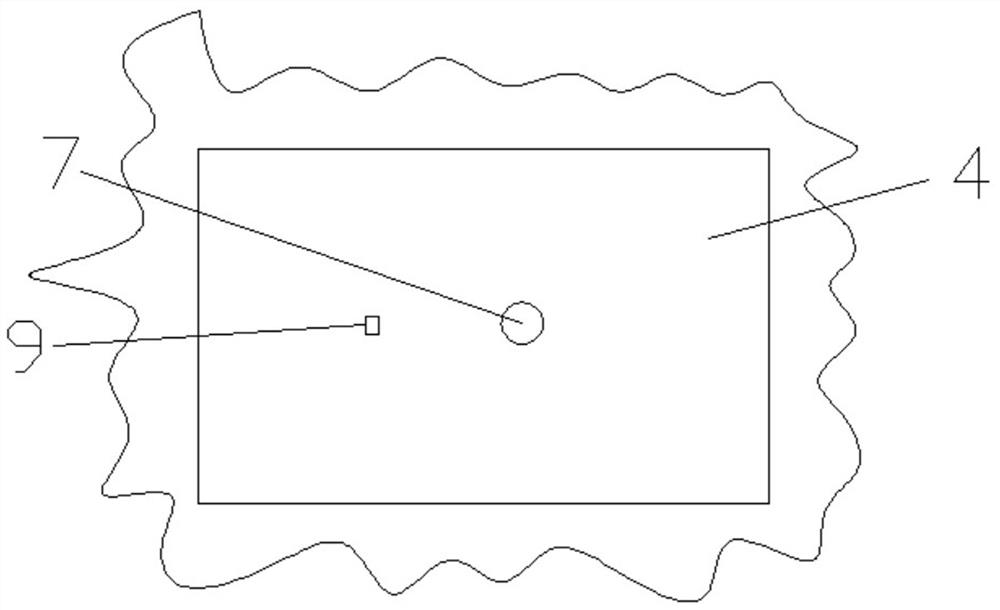

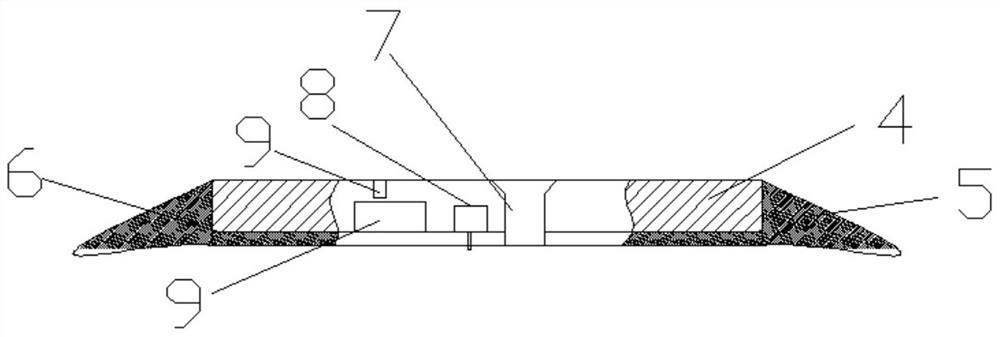

[0023] Example: such as Figure 1 to Figure 5 As shown, including the road surface 1, the top surface of the road surface 1 is provided with a crack 2 downwards, and the top surface of the road surface 1 is provided with a cover plate 4. The cover plate 4 is a flat plate structure arranged horizontally. The front side, rear side, and left side of the cover plate 4 , The right side is provided with a heat-resistant silicone skirt 5, and the bottom surface of the cover plate 4 is provided with a heat-resistant silicone sheet 6 arranged horizontally. Through the injection port 7 of the cover plate 4, the inside of the cover plate 4 is a hollow structure, and the relative position inside the cover plate 4 is provided with a micro switch 8, a control box 17, and an LED lamp bead 9, and the micro switch 8 is provided with a vertically downward The driving rod, the driving rod penetrates the cover plate 4 and the heat-resistant silica gel sheet 6 downwards, the led lamp beads 9 are v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com