Common-rail high-pressure oil inlet/outlet valve assembly and common-rail high-pressure oil supply pump

A technology of oil inlet and outlet valves and oil inlet valves, which is applied in the field of common rail, can solve the problems of complex structure of oil inlet and outlet valve components, unreasonable arrangement of oil inlet passages, and low oil filling efficiency, so as to improve oil filling efficiency and oil passage layout Reasonable, high oil filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

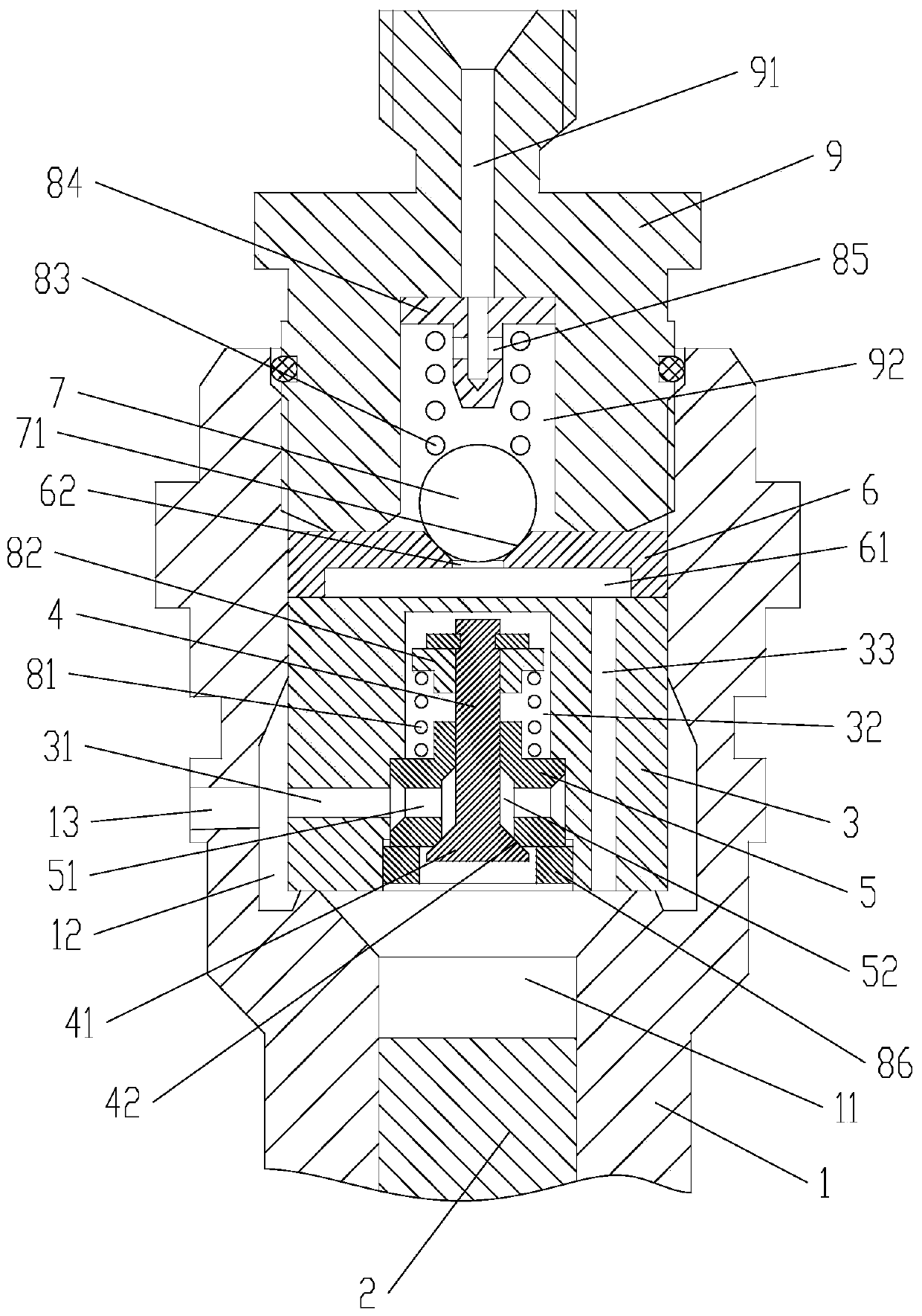

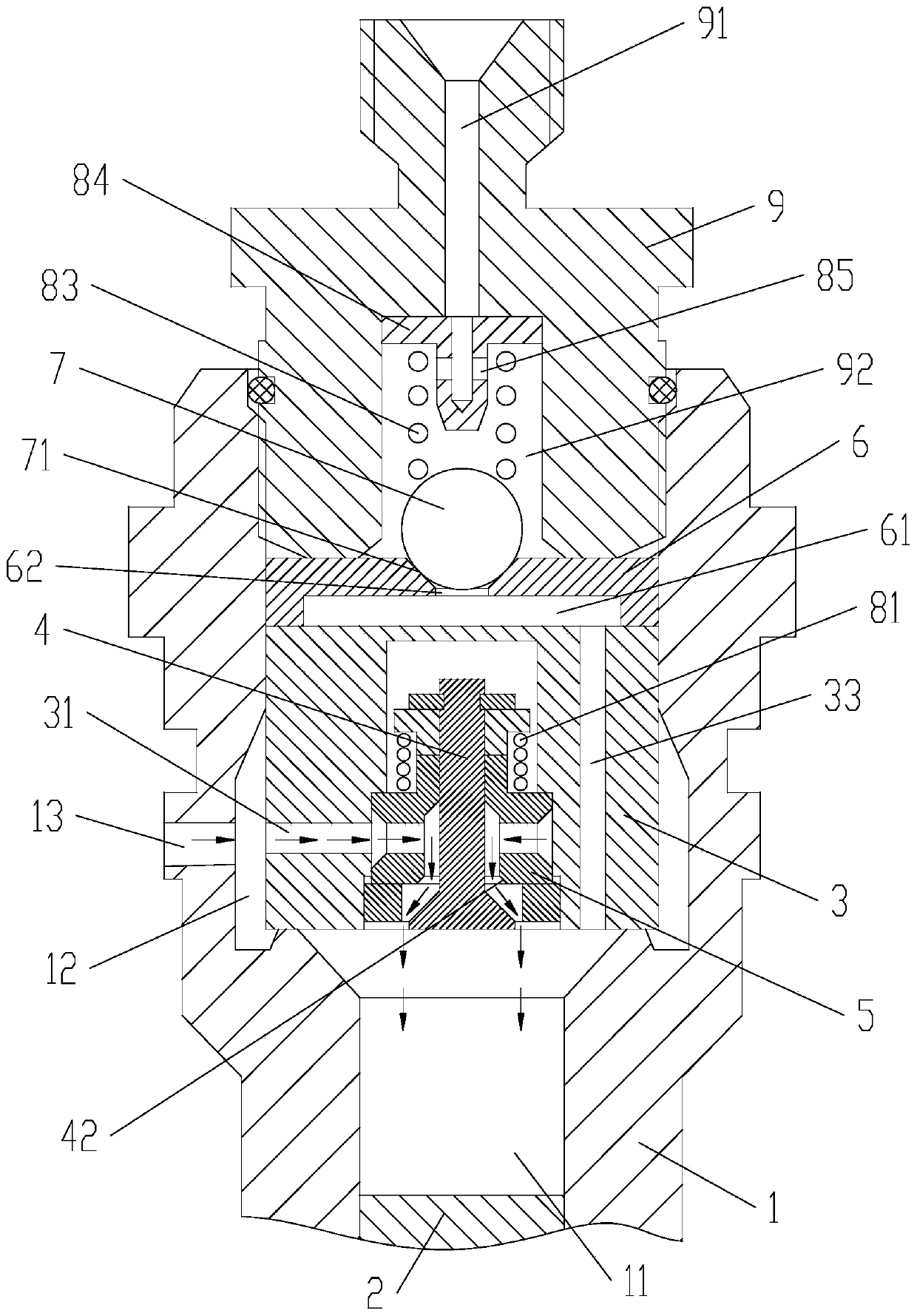

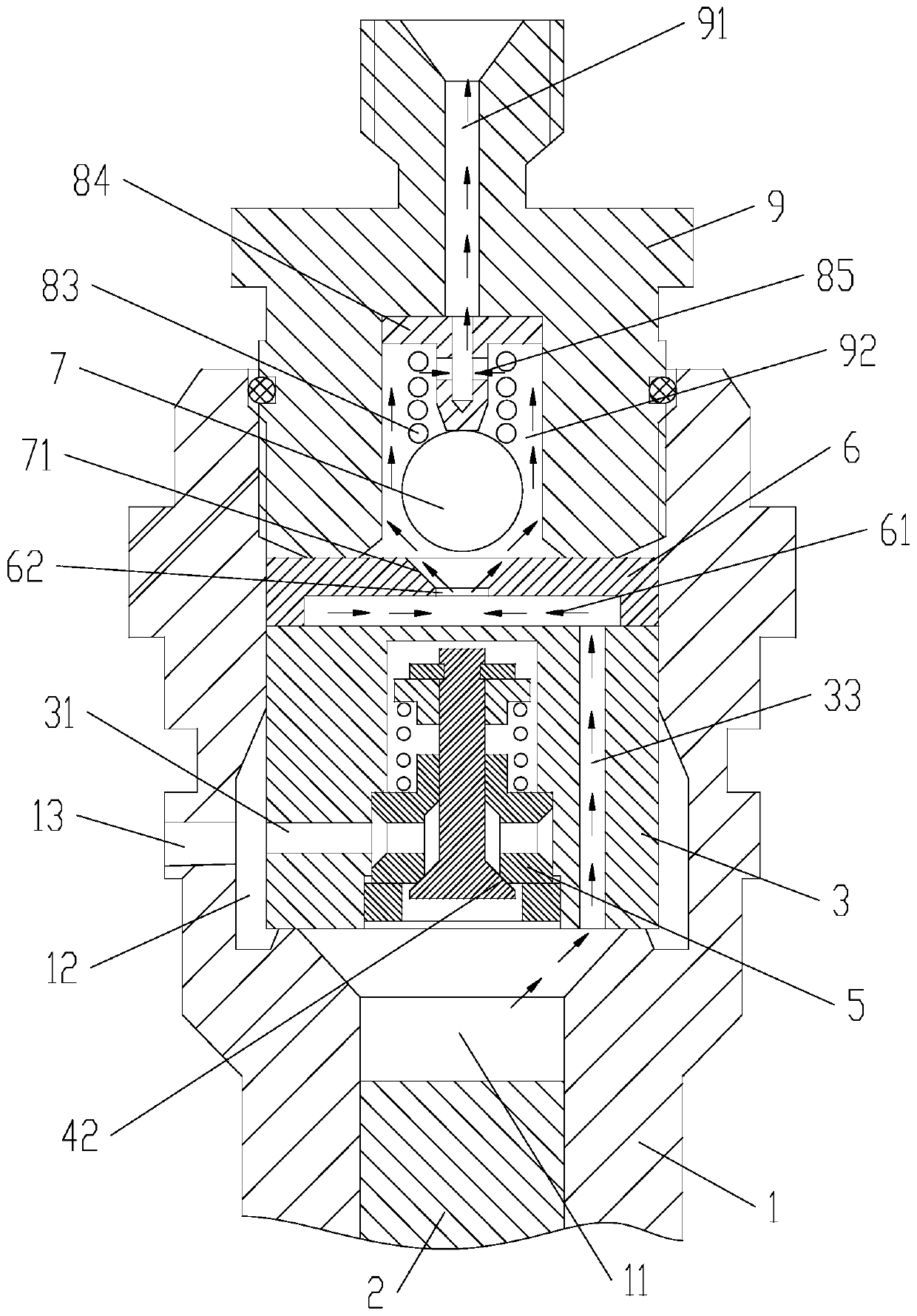

[0032] Such as Figure 1 to Figure 4 As shown, a common rail high-pressure oil inlet and outlet valve assembly includes a plunger sleeve 1, and the plunger sleeve 1 is provided with a plunger cavity 11, a connecting cavity and an oil inlet hole 13, and the connecting cavity is connected to the plunger cavity 11 and the oil inlet hole 13 respectively. The holes 13 communicate with each other; the plunger 2 is slidably inserted into the plunger cavity 11; and the oil outlet joint 9 is sealed and installed on the connection cavity, and the oil outlet joint 9 is provided with a seventh oil passage 91; Also includes the oil inlet valve seat 3, the oil inlet valve seat 3 is sealed and installed in the connecting cavity, and is sealed with the plunger cavity 11, the oil inlet valve seat 3 is provided with a first oil passage 33 and communicates with the oil inlet hole 13 and the column The second oil passage 31 and the first oil passage 33 of the plug chamber 11 communicate with the ...

Embodiment 2

[0052] Such as Figure 5 As shown, the common-rail high-pressure oil supply pump includes a common-rail high-pressure oil inlet and outlet valve assembly; an oil delivery pump 101; a cam device 106, which is connected to the diesel engine gear train, and the cam device 106 is also connected to the oil delivery pump 101 and the common-rail high-pressure valve respectively. The plunger 2 of the oil inlet and outlet valve assembly is connected; the fuel metering valve 105, the fuel metering valve 105 is connected with the fuel delivery pump 101 and the oil inlet hole 13 respectively; the filter 102, the filter 102 is connected with the fuel delivery pump 101; the fuel tank 103, the fuel tank 103 is connected with fuel pump 101 and filter 102 respectively; Connected with fuel tank 103.

[0053] When the common rail high-pressure fuel supply pump starts, the common rail high-pressure fuel supply pump drives the fuel delivery pump 101 to rotate through the cam device 106 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com