Coaxiality measuring device and method for large-span shaft hole part

A coaxiality measurement and large-span technology, applied in the field of mechanical processing, can solve the problems of difficult manufacturing process of the process shaft, poor versatility, difficulty in guaranteeing the straightness and coaxiality of the process shaft, etc., and achieves low cost, simple structure, The effect of the small influence of its own structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

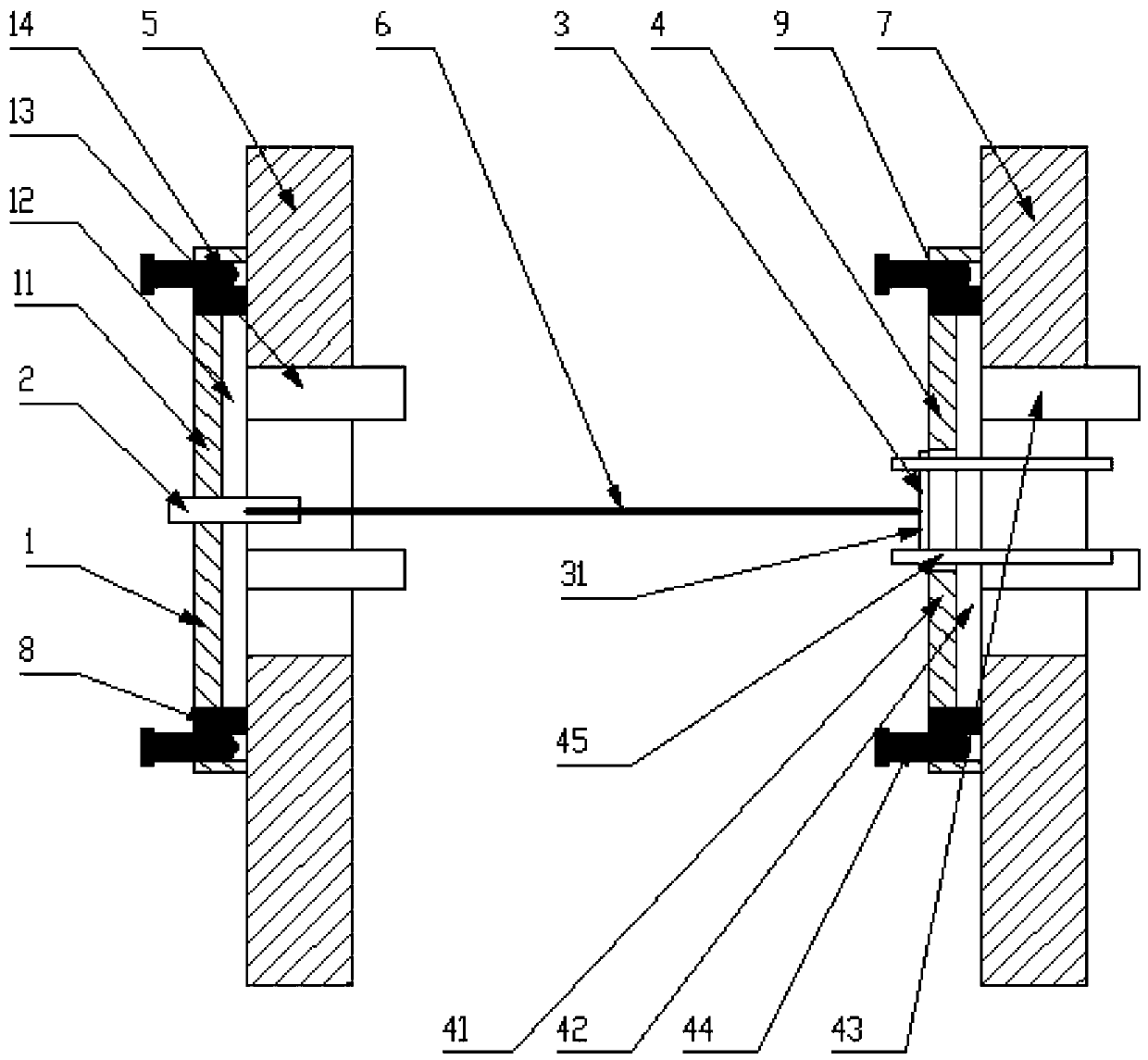

[0031] Such as figure 1 As shown, in a schematic embodiment of the piston-cylinder coaxiality measuring device provided by the present invention, the measuring device includes an axis aligning mechanism 1, a laser source component 2, a position display component 3 and an axis aligning mechanism 2 4. Among them, the axis aligning mechanism 1 is installed on the component to be detected 1 5 to determine the axis of the component to be detected 5; the axis aligning mechanism 2 4 is installed on the component to be detected 2 7 to determine the axis of the component to be detected The axis of two 7; the laser source part 2 is used to emit the reference laser beam 6 coincident with the axis of the component to be detected one 5; the position display part 3 is installed on the axis alignment mechanism two 4, and is used to receive the reference laser beam 6, By measuring the distance between the laser spot and the center point of the position display component, the distance value i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com