Blast furnace hearth state determination method and device and electronic equipment

A determination method and blast furnace technology, applied in the field of smelting, can solve the problems of intensified erosion of carbon bricks in the hearth, unfavorable for the longevity and safety of the blast furnace, and inactivity of the hearth.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] In order to facilitate the understanding of this embodiment, the electronic equipment for implementing the method for determining the hearth state of a blast furnace disclosed in the embodiment of the present application is first introduced in detail.

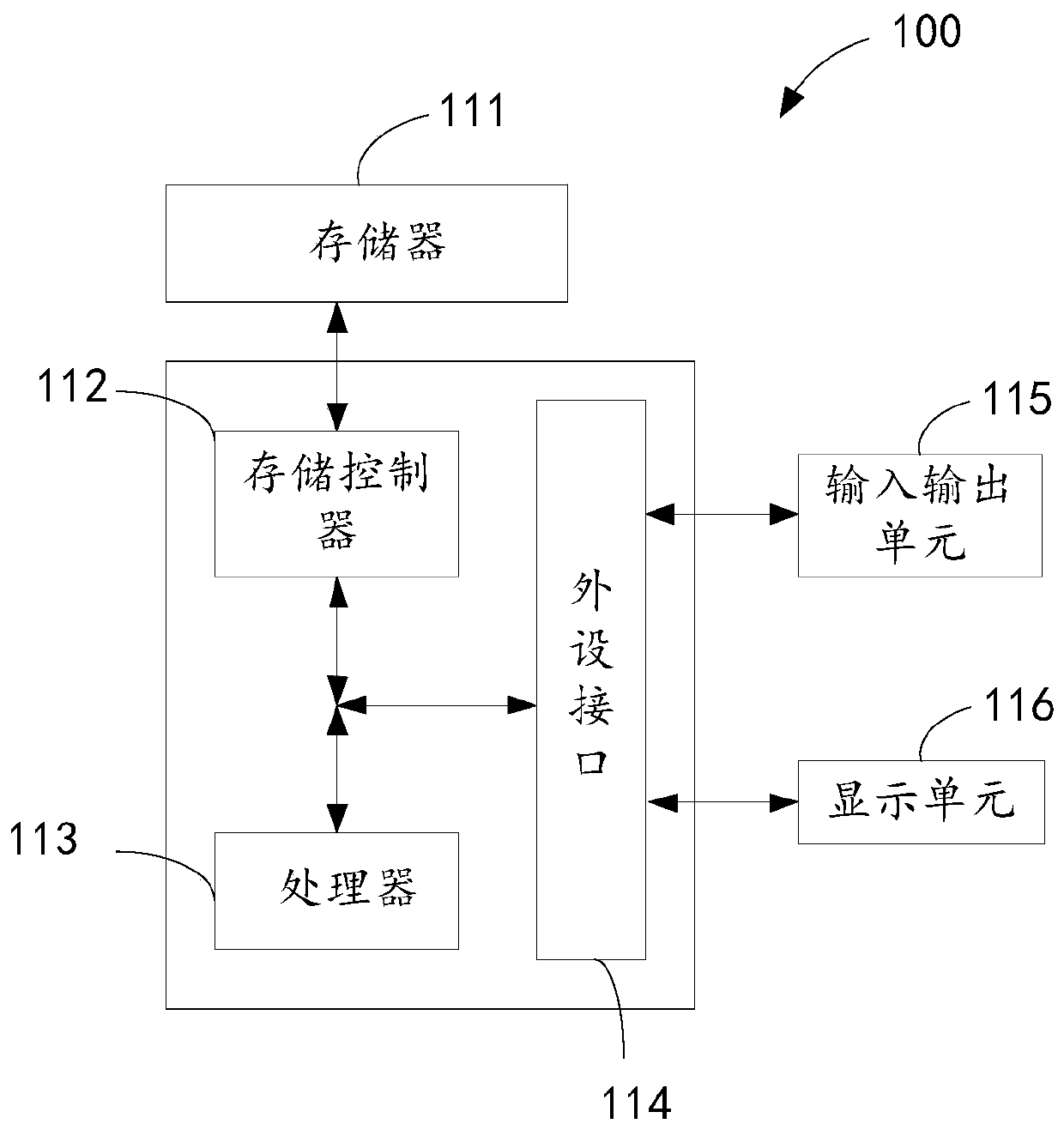

[0061] Such as figure 1 Shown is a block diagram of the electronic device. The electronic device 100 may include a memory 111 , a storage controller 112 , a processor 113 , a peripheral interface 114 , an input and output unit 115 , and a display unit 116 . Those of ordinary skill in the art can understand that, figure 1 The shown structure is only for illustration, and does not limit the structure of the electronic device 100 . For example, the electronic device 100 may also include a ratio figure 1 more or fewer components than shown in, or with figure 1 Different configurations are shown.

[0062] The memory 111 , storage controller 112 , processor 113 , peripheral interface 114 , input / output unit 115 and displa...

Embodiment 2

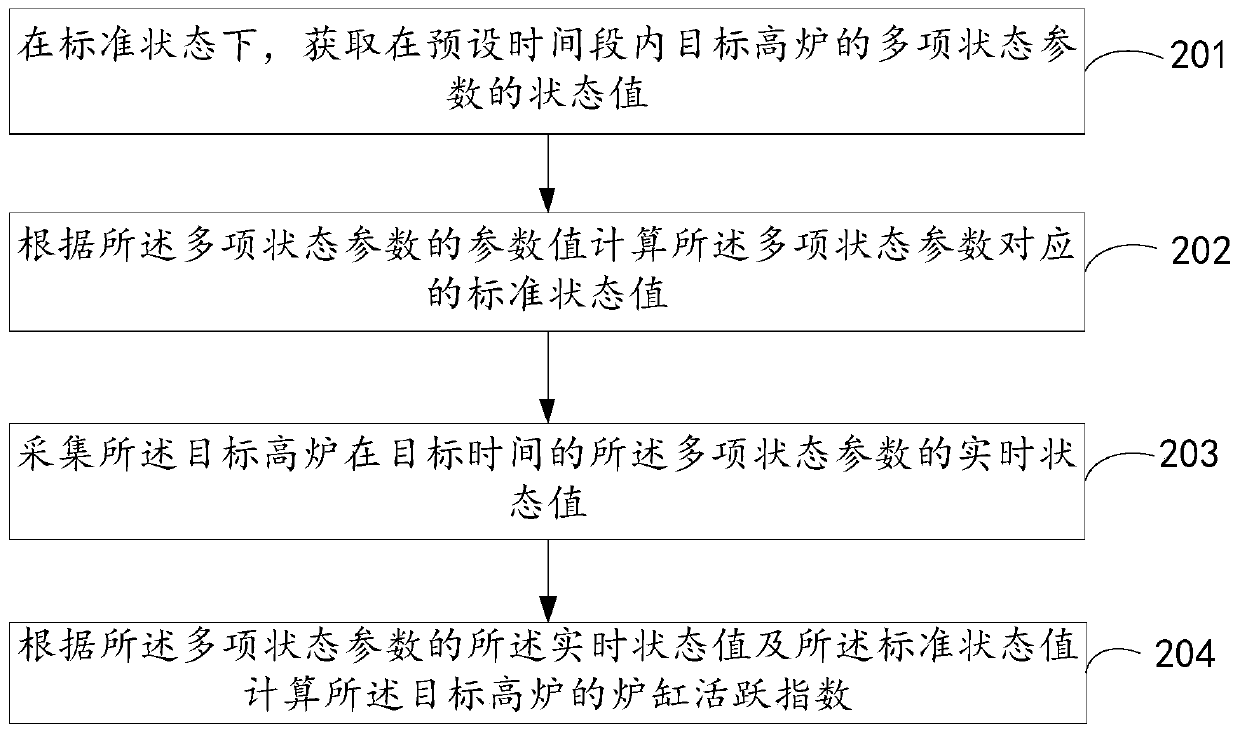

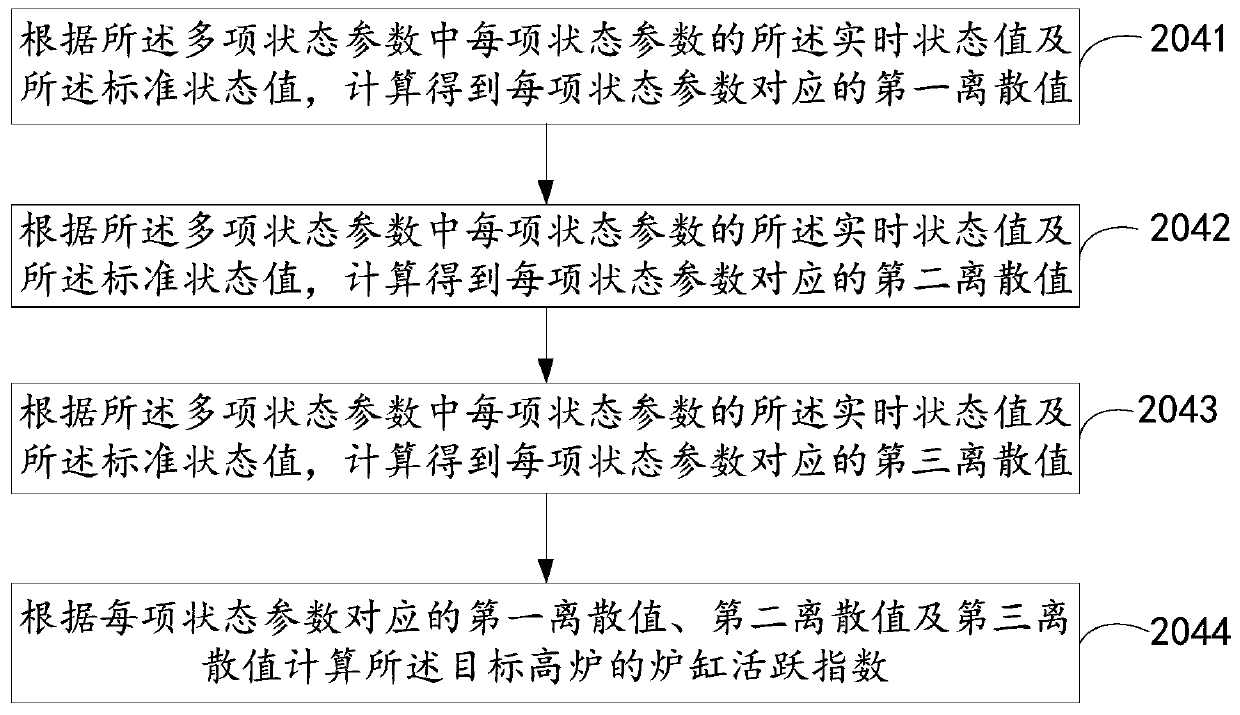

[0070] see figure 2 , is a flow chart of a method for determining a state of a blast furnace hearth provided by an embodiment of the present application. The following will be figure 2 The specific process shown will be described in detail.

[0071] Step 201, under the standard state, obtain the state values of multiple state parameters of the target blast furnace within a preset time period.

[0072] Exemplarily, the above-mentioned standard state may refer to a state in which various production indicators of the target blast furnace are relatively good. Optionally, the standard state may be a cycle period when the target blast furnace is in the full-air and full-oxygen smelting state.

[0073] Exemplarily, the multiple state parameters may include: furnace core temperature, molten iron temperature, slag viscosity, tapping time, slag tapping rate, iron amount difference, wind speed, and theoretical combustion temperature.

[0074] Wherein, the furnace core temperature...

Embodiment 3

[0181] Based on the same application concept, the embodiment of the present application also provides a blast furnace hearth state determination device corresponding to the method for determining the state of the blast furnace hearth. Since the problem-solving principle of the device in the embodiment of the present application is the same as that of the above-mentioned blast furnace hearth in the embodiment of the present application The method for determining the state is similar, so the implementation of the device can refer to the implementation of the method, and the repetition will not be repeated.

[0182] see Figure 5 , is a schematic diagram of the functional modules of the device for determining the hearth state of the blast furnace provided in the embodiment of the present application. Each module in the device for determining the hearth state of the blast furnace in this embodiment is used to execute each step in the above method embodiment. The blast furnace hea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com