Side wall electrode resistive random access memory structure and preparation method thereof

A resistive variable storage and electrode technology, which is applied in the field of memory, can solve the problems of difficult control of etching morphology, limited height of through holes, and difficult etching process, etc., and achieve the advantages of embedded integration, size reduction, and height reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

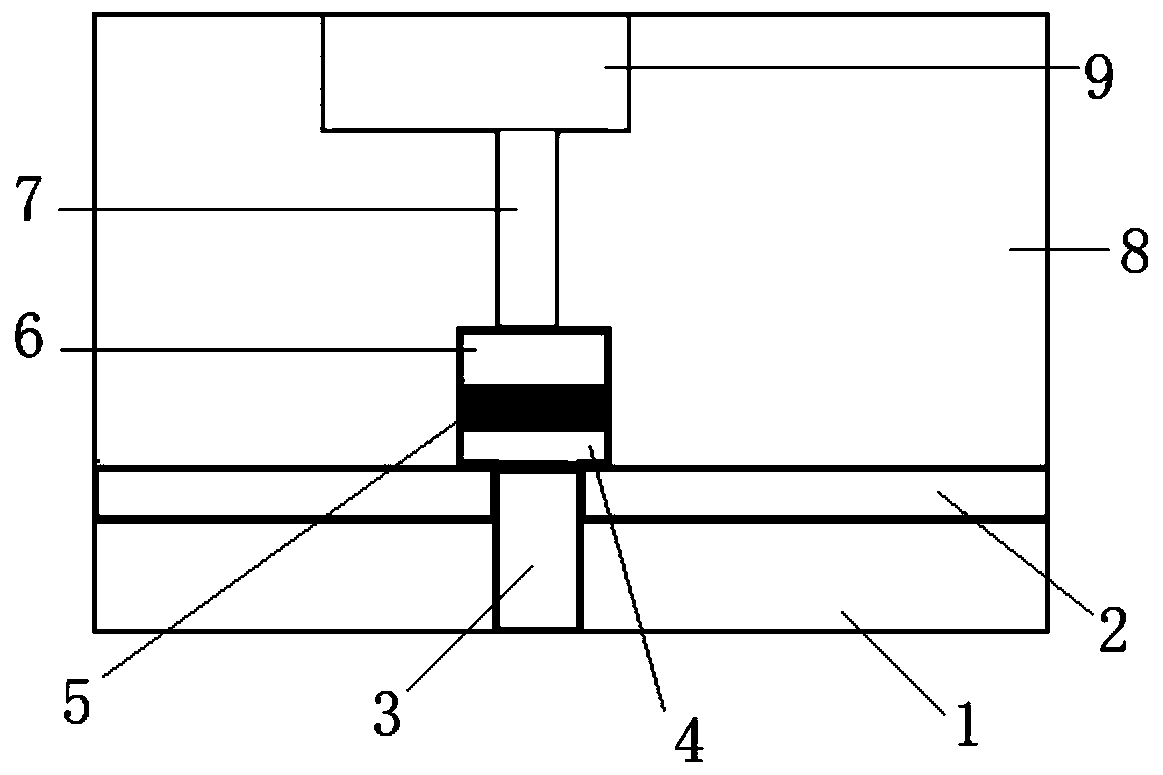

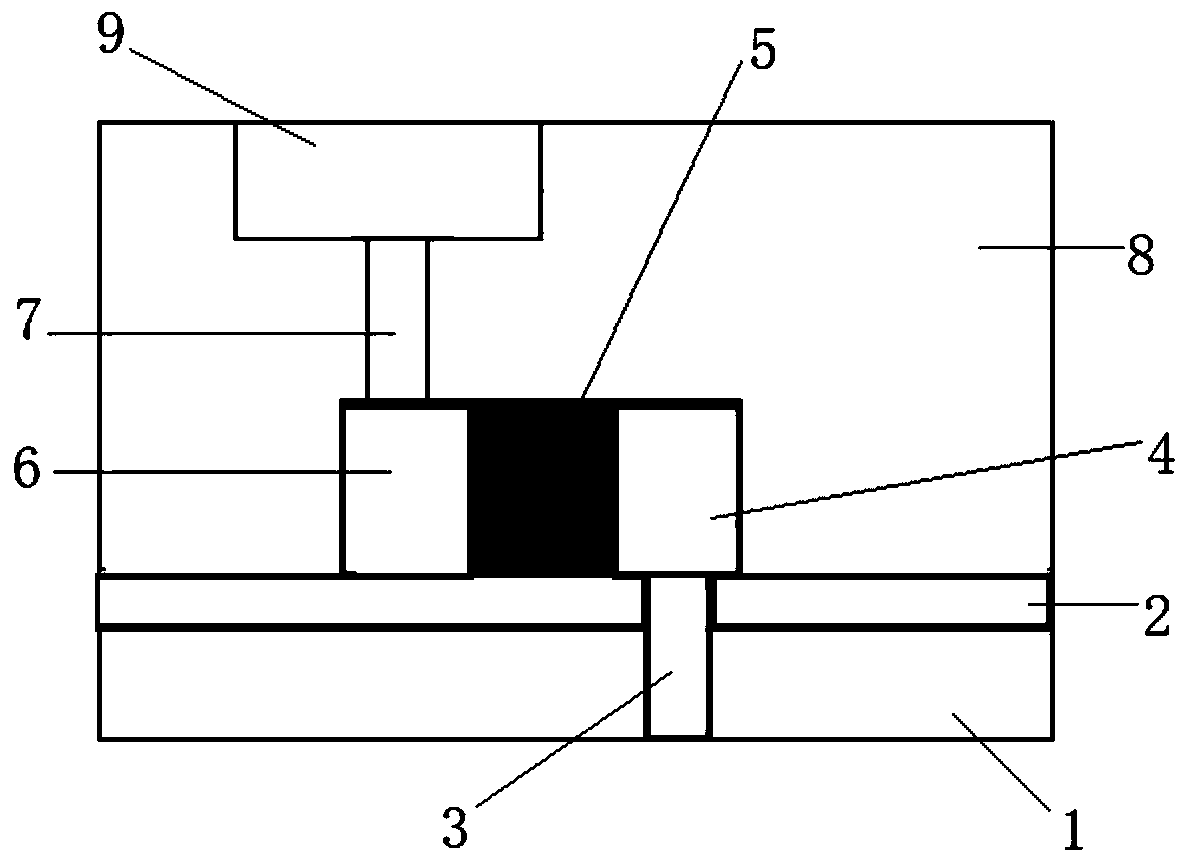

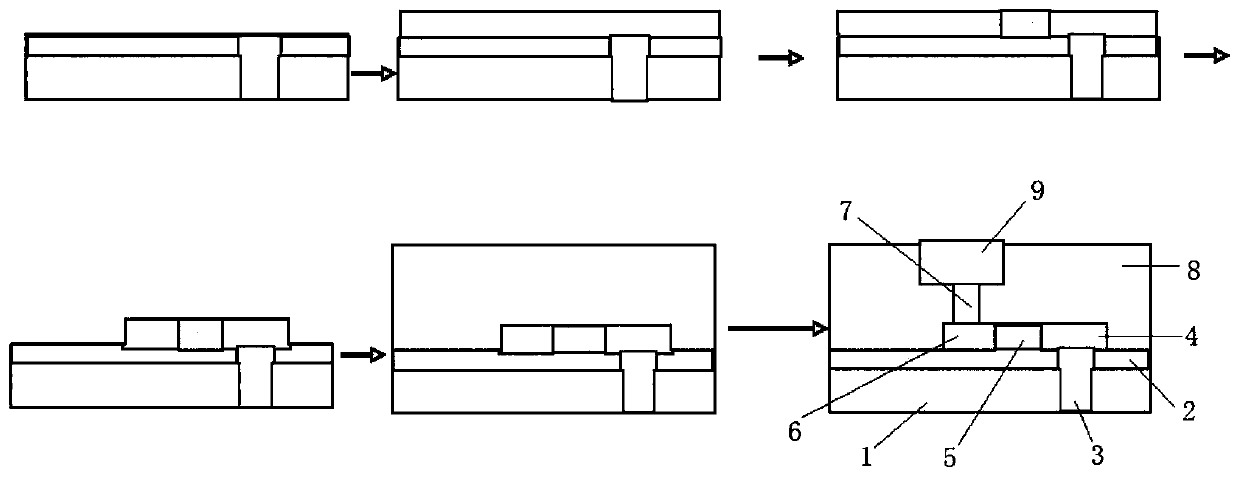

[0047] This embodiment also provides a method for preparing a sidewall electrode resistive memory structure, including:

[0048] S1. Providing a first dielectric layer;

[0049] S2. Depositing and forming a low-mobility material layer on the first dielectric layer;

[0050]S3. Prepare a first through hole penetrating through the low mobility material layer and the first dielectric layer;

[0051] S4. Forming a first metal plug in the first through hole;

[0052] S5. Depositing an electrode material layer on the low mobility material layer;

[0053] S6. Open a channel on the electrode material layer that penetrates up and down and divides the electrode material layer into left and right parts, and deposits a resistive material in the channel to form a resistive layer;

[0054] S7, patterning the electrode material layer to form a first electrode and a second electrode.

[0055] In some embodiments, the method also includes:

[0056] S8. Depositing and forming a second diel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com