Implementation method of power LED pulse light source

A technology of pulsed light source and implementation method, applied in the field of LED light source, can solve the problems of increasing the design complexity of the pulsed light source, affecting the design reusability, increasing the use cost, etc., to achieve the effect of increasing portability, satisfying timely response, and convenient adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

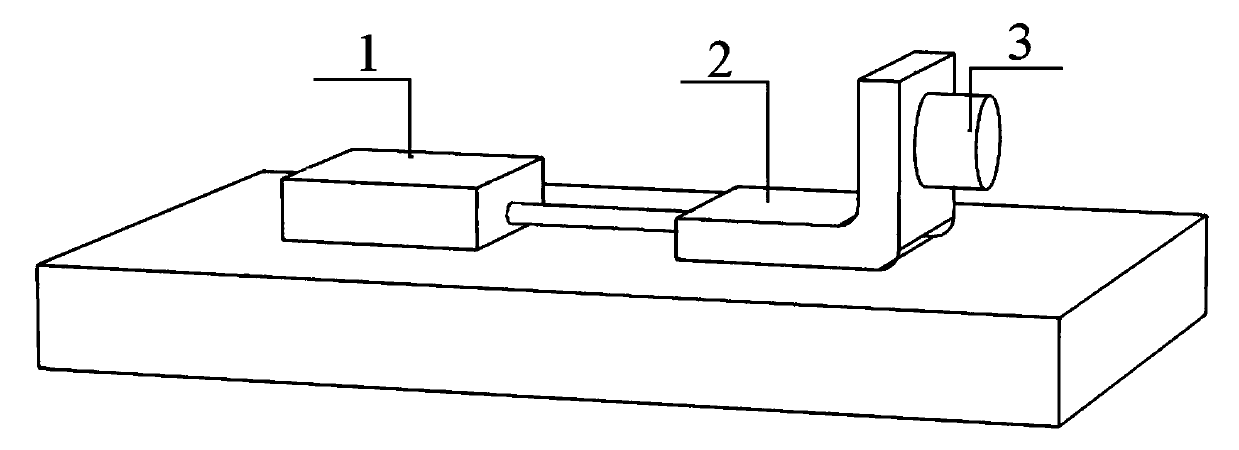

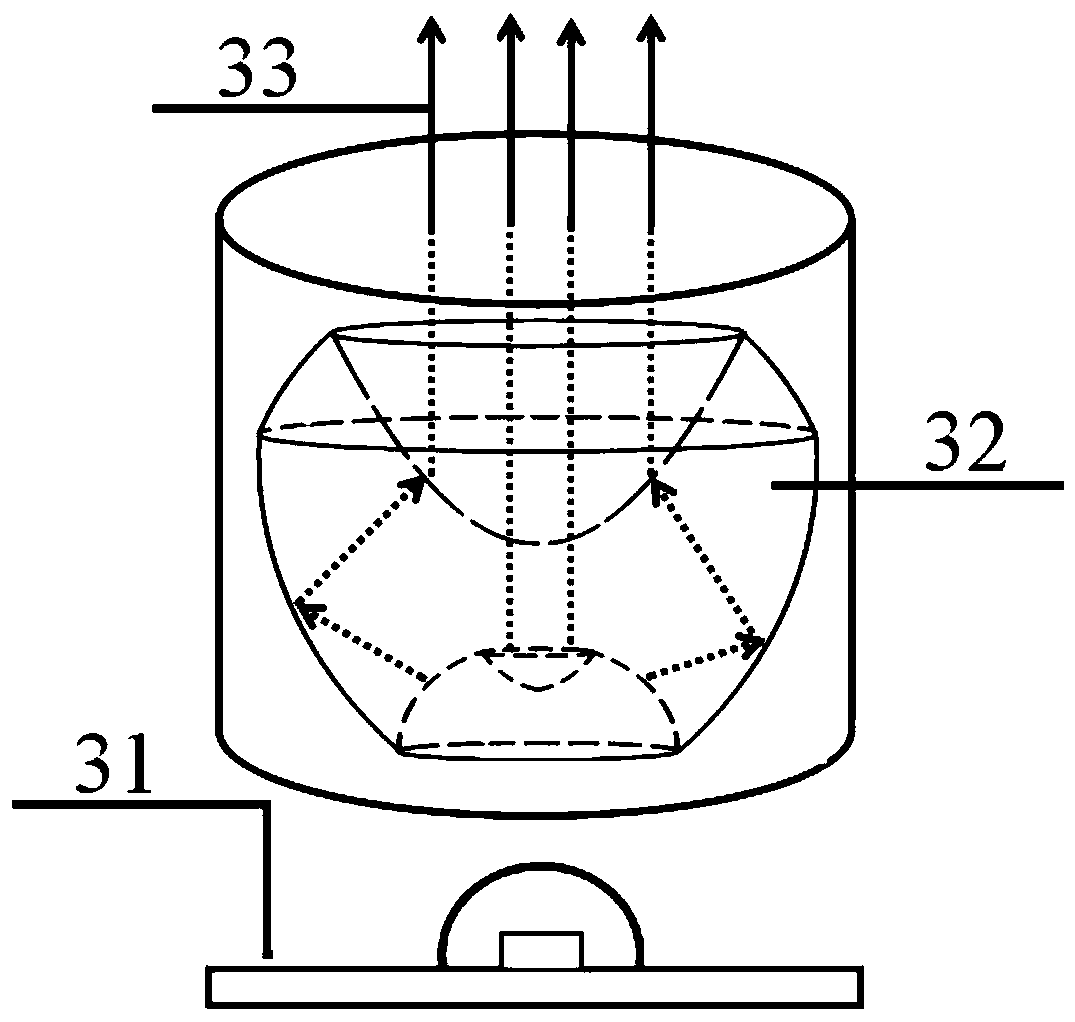

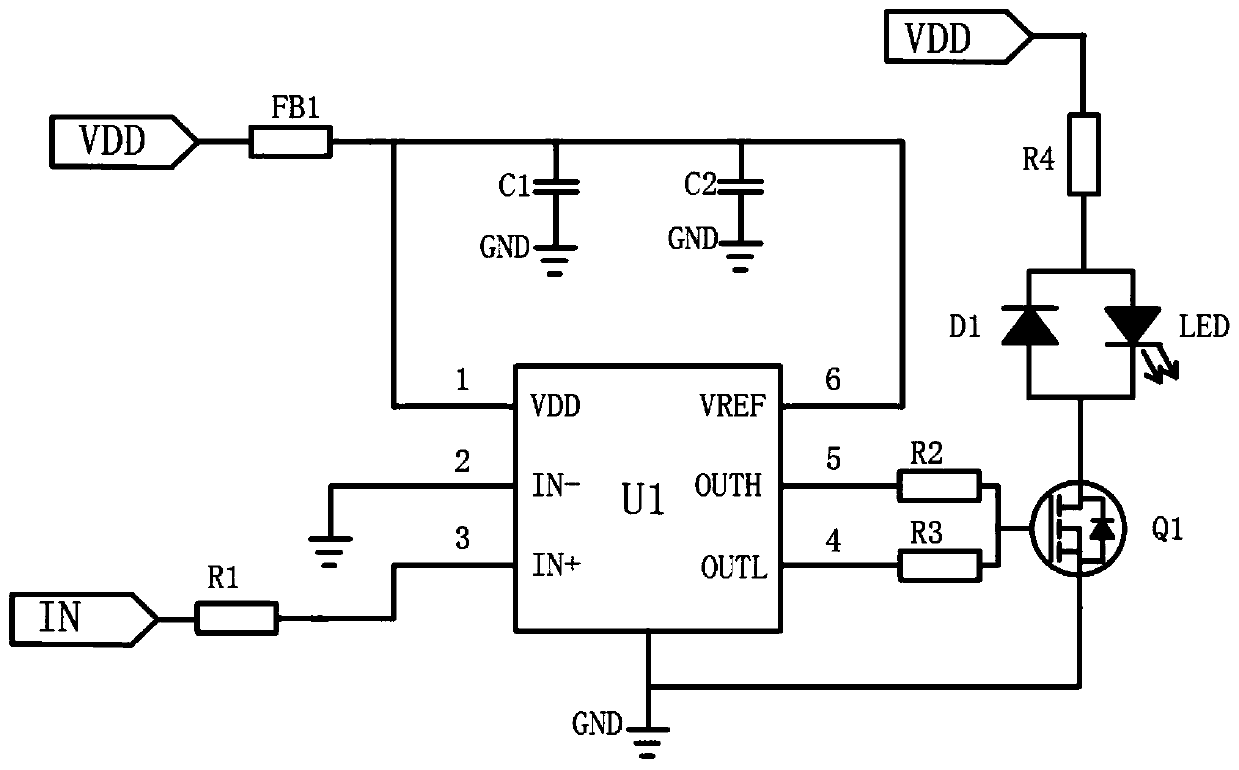

[0030] Embodiment 1, see figure 1 , a method for realizing a power-type LED pulse light source, including a pulse signal generating module 1, a drive circuit module 2, and an LED pulse light source module 3; wherein: the pulse signal generating module 1 is mainly composed of an FPGA chip, a crystal oscillator, a JTAG download interface and related configurations According to the requirements of the required pulse signal, the program is written in VHDL language, and the specific pulse signal is output directly through I / O; the driving circuit module 2 selects the appropriate The field effect tube driver U1 is used to drive the corresponding high-speed field effect tube, so that the circuit can achieve nanosecond response to achieve stable and continuous pulse output; the LED pulse light source module 3 is composed of a power type LED light source and a collimating lens. Through secondary light distribution, the LED pulse light source outputs parallel collimated beams.

Embodiment 2

[0031] Example 2, see Figure 4 , there is an embodiment to realize an optical pulse signal with a repetition frequency of 10 kHz and a pulse width of 50 ns. That is, through program writing and burning, the pulse signal generation module outputs the required electrical pulse signal a at the I / O, and the pulse signal a is input into the drive circuit module through electrical connection, and the FET responds quickly under the control of the pulse signal, and the control The LED pulse light source module works in a pulse mode to generate a predetermined optical pulse signal b.

[0032] The invention relates to a method for realizing a power type LED pulse light source, in which, except a pulse signal generation module which needs a 5V DC voltage for power supply, other parts can be powered by a DC adjustable power supply.

[0033] The invention relates to a method for realizing a power type LED pulse light source, wherein the power type LED light source is used as the pulse li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com