Cooler and thermosyphon

A thermosyphon, cooler technology, applied in indirect heat exchangers, electrochemical generators, lighting and heating equipment, etc., can solve the problems of unstable liquid refrigerant supply, unstable cooling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

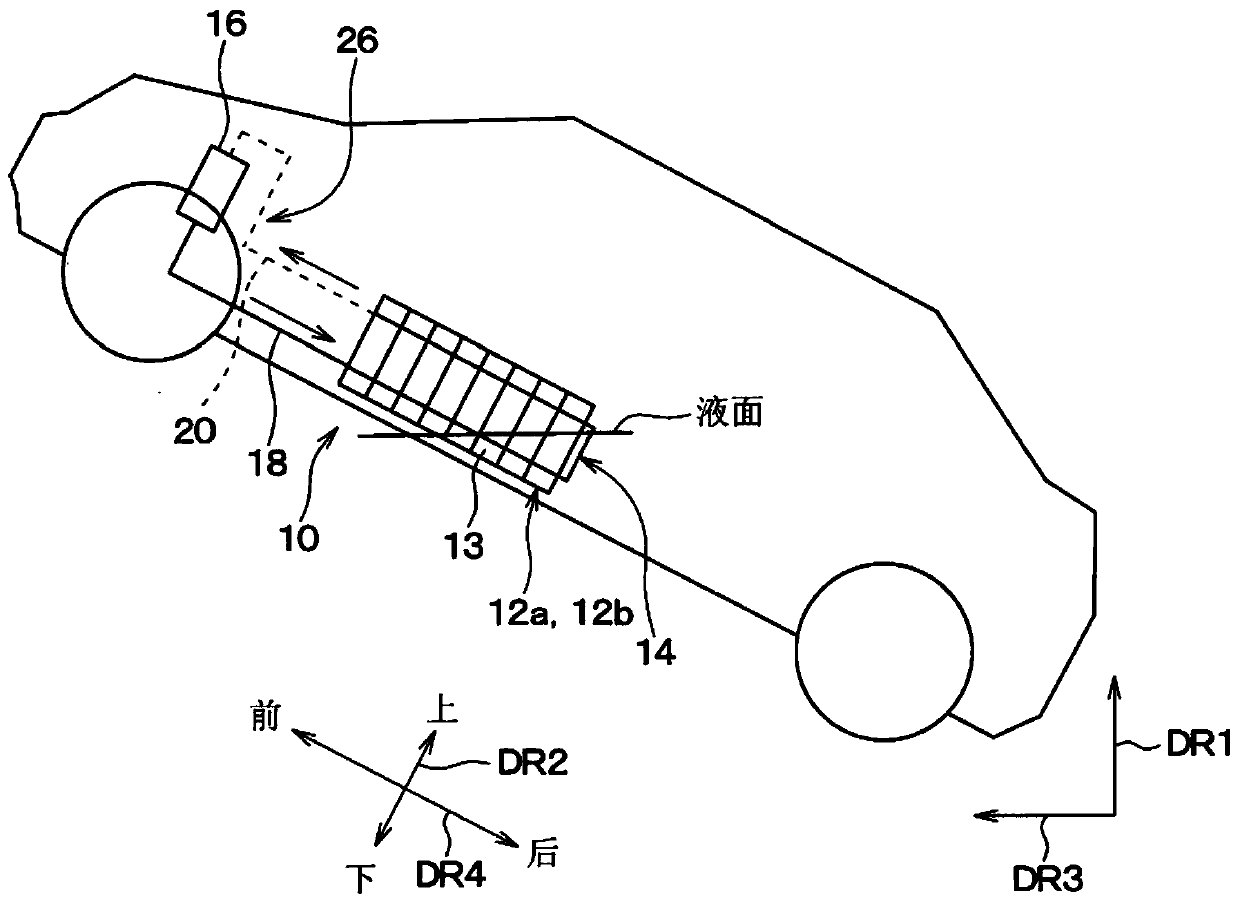

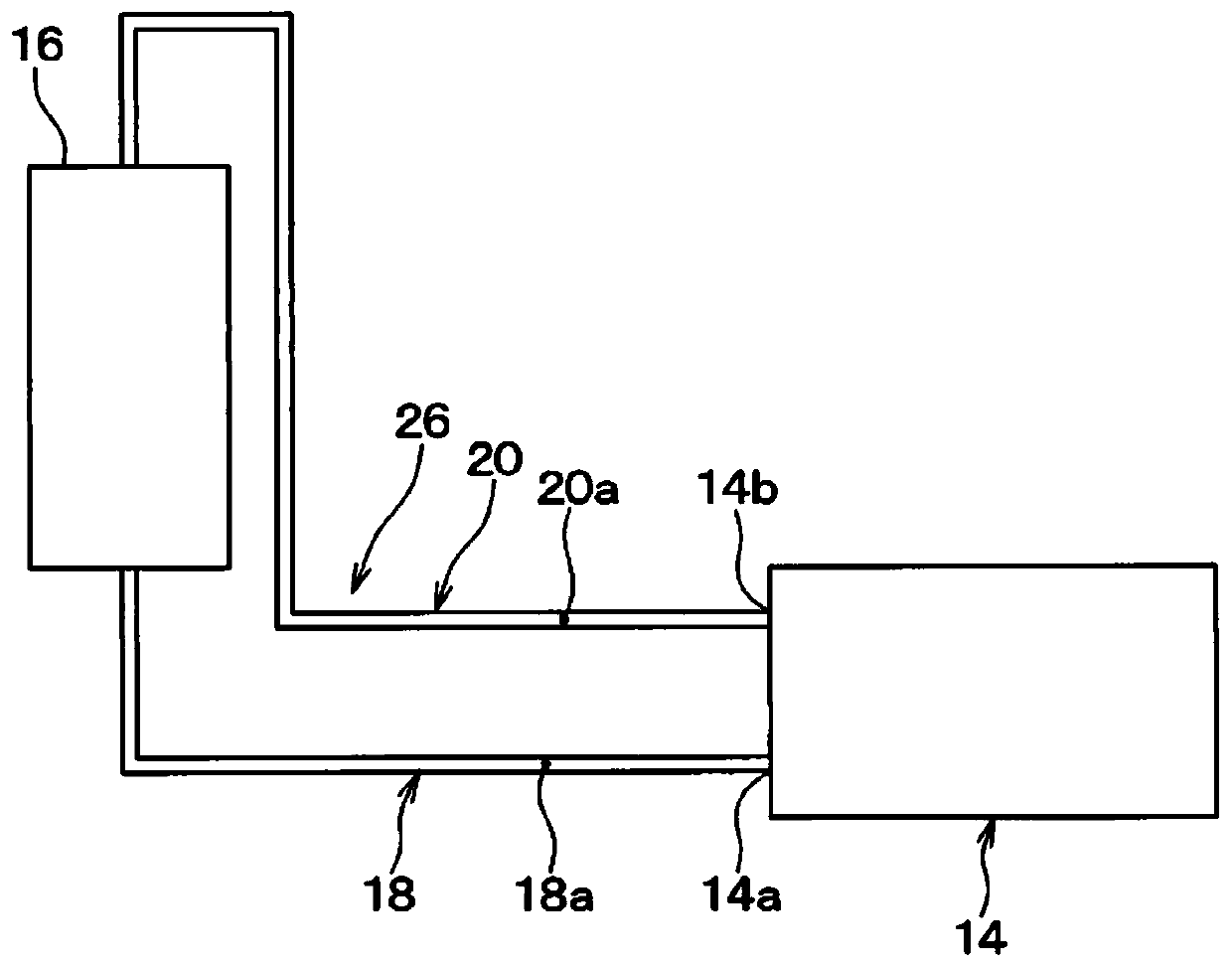

[0076] figure 1 The battery cooling unit 10 of the present embodiment shown is installed in electric vehicles such as electric vehicles and hybrid vehicles. Furthermore, in the present embodiment, the battery cooling unit 10 cools the secondary batteries 12a and 12b mounted on the electric vehicle. That is, the object to be cooled by the battery cooling unit 10 is the secondary batteries 12a and 12b.

[0077] In an electric vehicle equipped with a battery cooling unit 10 (hereinafter, simply referred to as a "vehicle"), the electric power stored in a power storage device (in other words, a battery pack) including the secondary batteries 12a and 12b as constituent components is converted to Circuits and the like are supplied to the electric motor, whereby the vehicle travels. The secondary batteries 12a and 12b generate heat by themselves when outputting electric power to the electric motor via the inverter.

[0078] Moreover, if the temperature of the secondary batteries 1...

no. 2 approach

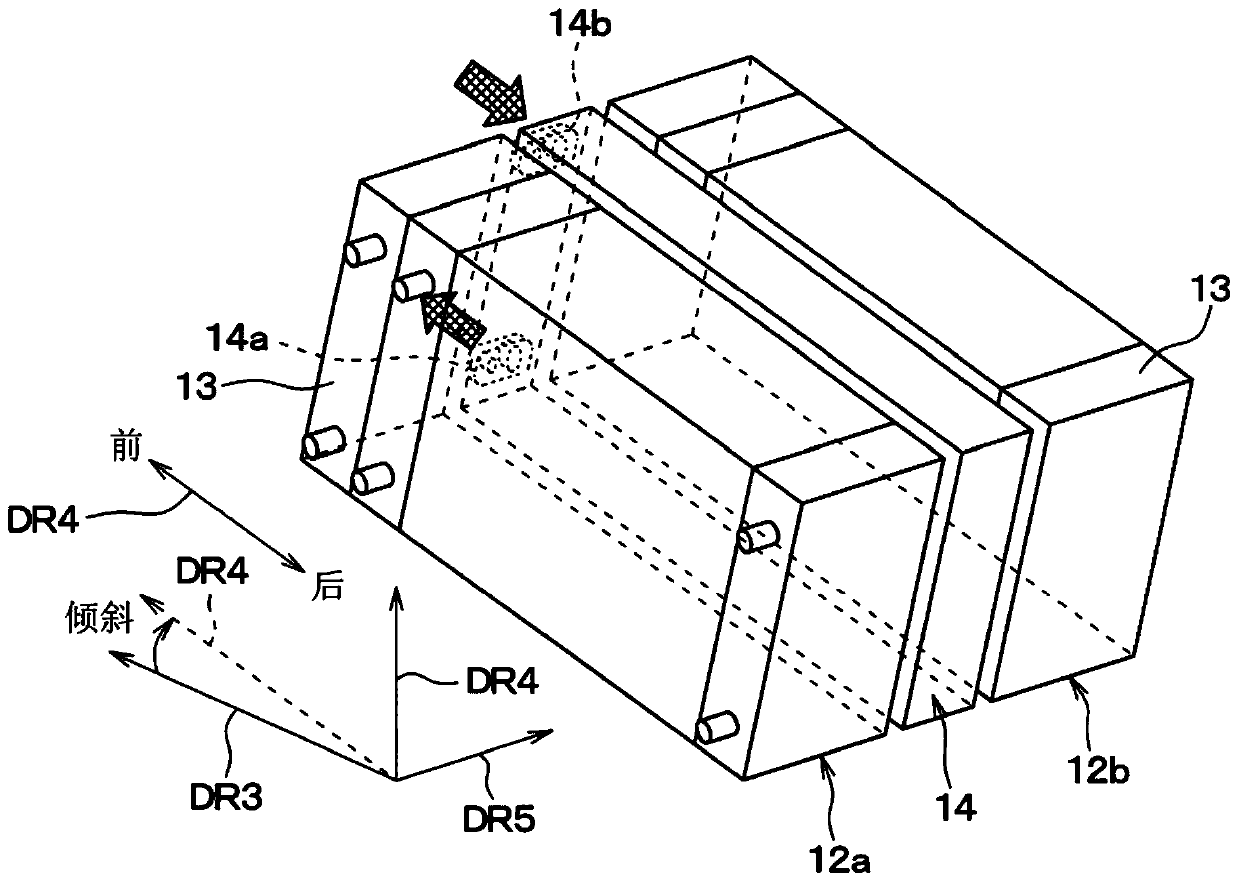

[0224] In this second embodiment, refer to Figure 15 ~ Figure 1 8. An example in which the battery cooling unit 10 is configured by connecting two coolers 14 of the above-mentioned first embodiment in series will be described.

[0225] The battery cooling structure for cooling the secondary batteries 12a and 12b using the cooler 14 is different between the present embodiment and the first embodiment described above. Therefore, below, the battery cooling structure in the battery cooling unit 10 will be described, and the description of other structures will be omitted.

[0226] The battery cooling unit 10 of the present embodiment includes two coolers 14 and two pairs of secondary batteries 12a and 12b as a battery cooling structure.

[0227] The two coolers 14 are configured in the same manner as the coolers 14 of the first embodiment described above. Two coolers 14 are arranged along the traveling direction of the vehicle. Hereinafter, for convenience of description, the ...

no. 3 approach

[0241] In the above-mentioned second embodiment, the example in which the two coolers 14 are arranged in the traveling direction of the vehicle has been described, but instead, refer to Figure 18A , Figure 18B , Figure 19A , Figure 19B The present third embodiment in which three coolers 14 are arranged in a line in the traveling direction of the vehicle will be described. Among the two coolers of the three coolers 14 , the cooler located on the front side in the traveling direction corresponds to the first cooler, and the cooler located on the front side in the traveling direction corresponds to the second cooler. The inlet 14a of the cooler 14 corresponding to the first cooler corresponds to the first refrigerant inlet, and the inlet 14a of the cooler 14 corresponding to the second cooler corresponds to the second refrigerant inlet.

[0242] The battery cooling structure for cooling the secondary batteries 12a and 12b using the cooler 14 is different between the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com