Collecting device for recycling lithium batteries

A collection device, lithium battery technology, applied in the direction of battery recycling, recycling technology, waste collector recycling, etc., can solve the problems of electrolyte leakage, broken lithium battery, and inability to recover electrolyte.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

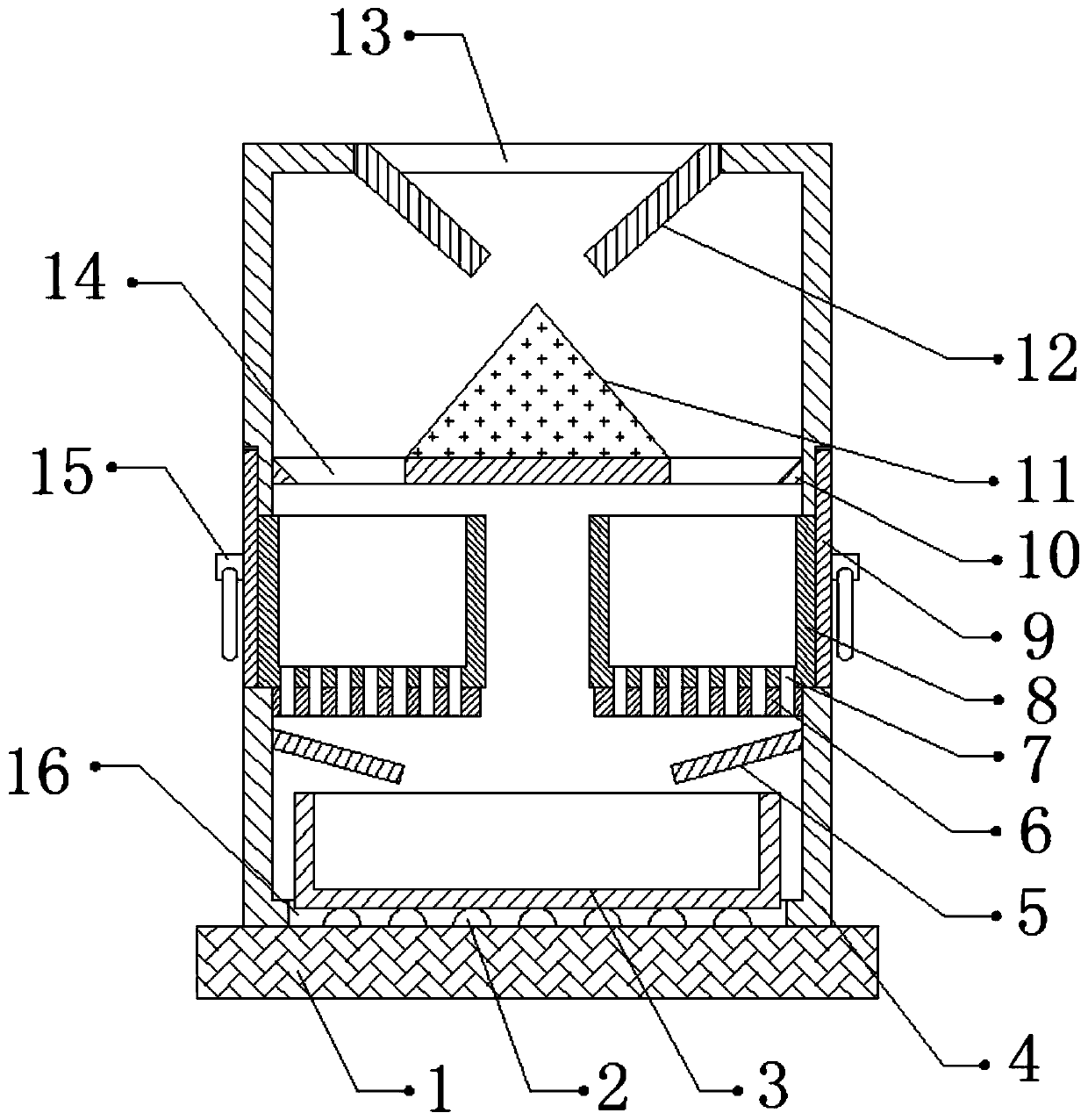

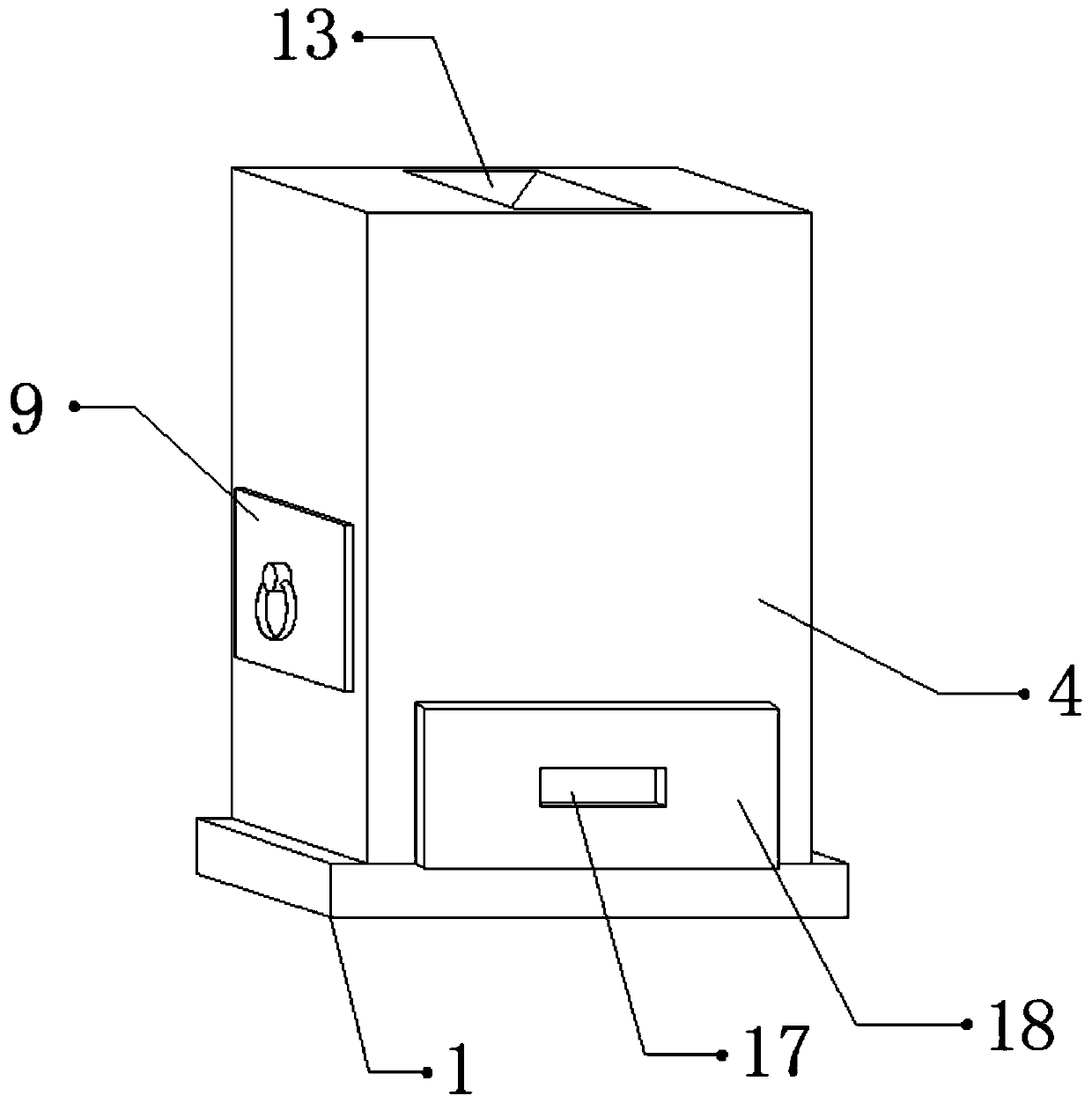

[0025] refer to Figure 1-2 , a collection device for lithium battery recovery, comprising a fixed seat 1, the top outer wall of the fixed seat 1 is connected with a collection box 4 by bolts, and one side of the outer wall of the collection box 4 is located at the bottom position to have a cleaning port 16, and the cleaning port 16 Both sides of the inner wall are plugged with collection tanks 3, and one side of the collection tank 3 is connected with a connecting plate 18 by bolts, one side of the connecting plate 18 is provided with a handle 17, and the top outer wall of the fixing seat 1 is provided with a ball groove. , and the inner wall of the ball groove is rollingly connected with the ball 2, forming a rolling connection between the ball 2 and the collection tank 3, the top outer wall of the collection box 4 is provided with a feed port 13, and the inner walls on both sides of the feed port 13 are connected by bolts A feed plate 12 is connected, sockets are opened on ...

Embodiment 2

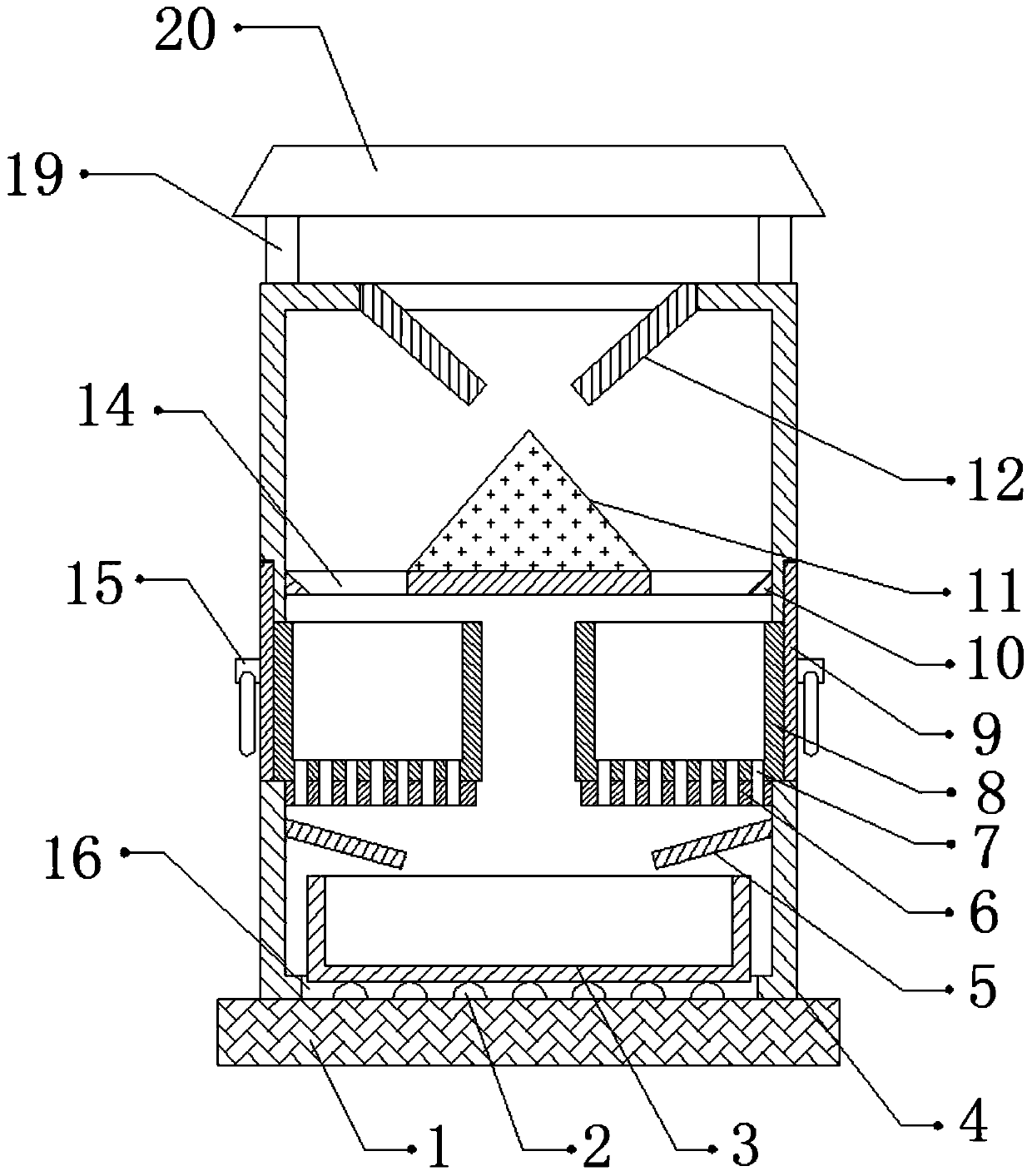

[0029] refer to image 3 , a collection device for lithium battery recovery. Compared with Embodiment 1, the two sides of the top outer wall of the collection box 4 are connected with fixed shafts 19 by bolts, and the top outer walls of the two fixed shafts 19 are connected by bolts. There are flashing 20.

[0030] Working principle: when in use, the lithium battery that needs to be recycled is recovered to the inside of the collection box 4 through the feed port 13 and the feed plate 12, and the lithium battery is collected into the inside of the collection box 8 through the port 14 through the drainage plate 11, Dry and wet separation of lithium batteries is carried out through the filter hole 7. When some lithium batteries are broken, the electrolyte will leak out, so that the electrolyte is collected into the collection tank 3 through the guide plate 5, preventing the electrolyte from leaking due to the broken lithium battery. The interior of the device is corroded and af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com