Industrial waste gas desulfurization, denitrification and dust removal device

A technology for desulfurization, denitrification and dust removal equipment, which is applied in the direction of gas treatment, combined devices, membrane technology, etc., can solve the problems of lower device efficiency, high cost, complex processing, etc., and achieve the effects of convenient liquid extraction, resource saving and improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

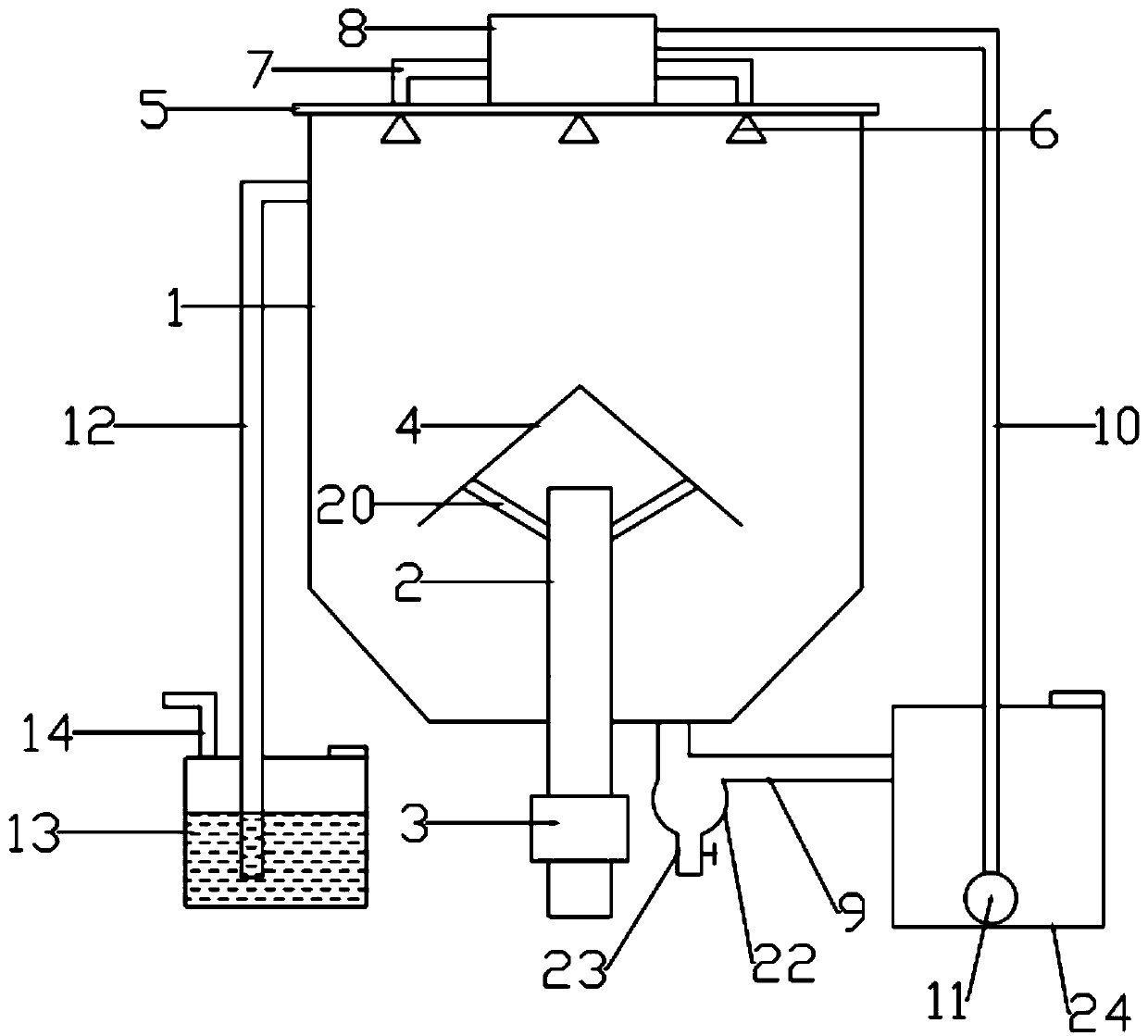

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings.

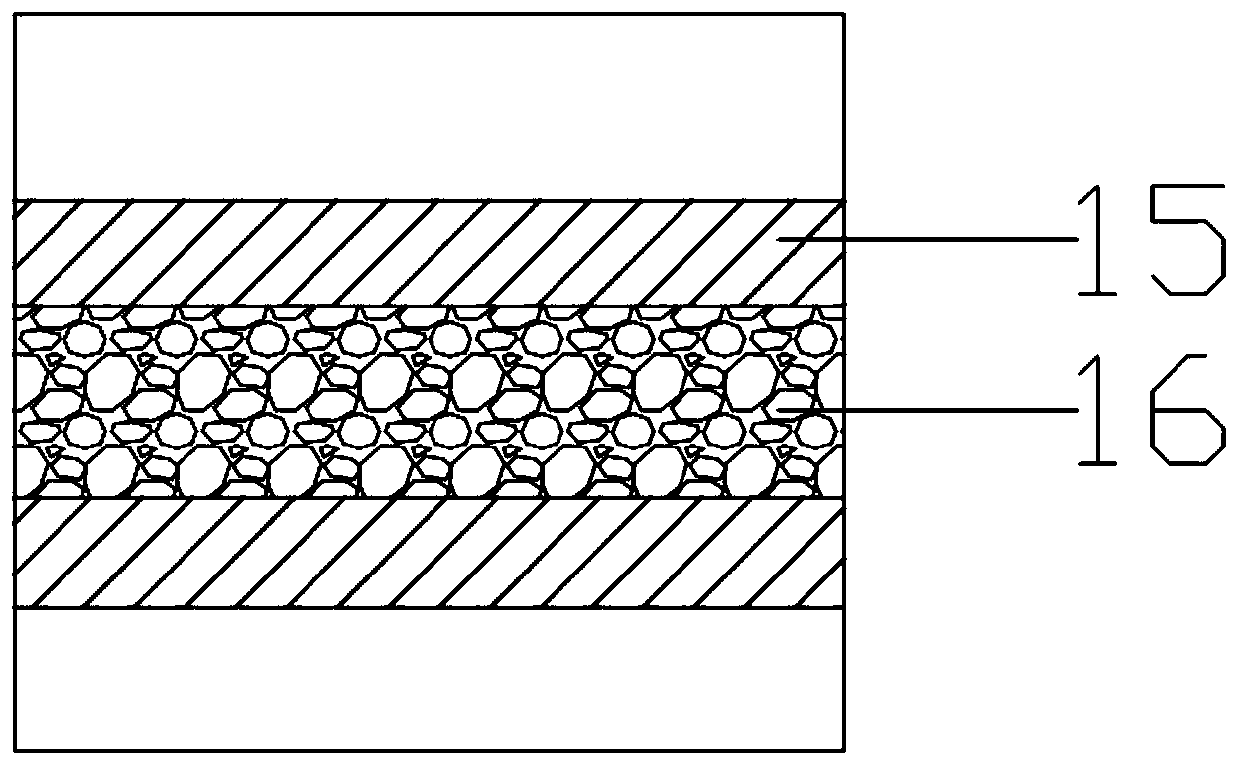

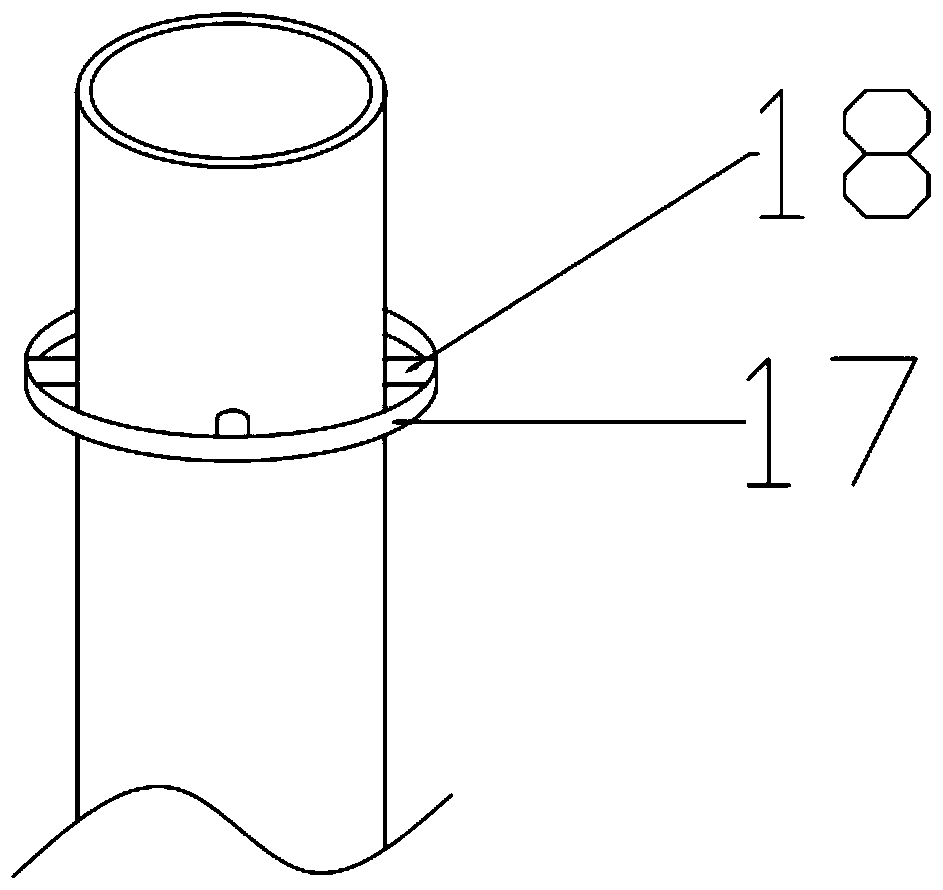

[0017] In conjunction with the accompanying drawings, an industrial waste gas desulfurization, denitrification and dust removal equipment includes a reaction tower 1, the bottom of the reaction tower 1 is connected to an air inlet pipe 2, one end of the air inlet pipe 2 is provided with a filter box 3, and the other end of the air inlet pipe 2 extends to the reaction tower. In the tower 1, a detachable cap 4 is provided on the top, a top cover 5 is provided on the top of the reaction tower 1, and a spray head 6 for spraying the treatment liquid is fixed on the inside of the top cover 5, and the spray head 6 is connected to the sprayer. Pipe 7, spray pipe 7 connect the high-pressure pump 8 that top cover 5 is fixedly arranged, the bottom of described reaction tower 1 connects circulation pipe one 9, and the end of circulation pipe one 9 leads into liquid storag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com