Paint spraying device for environment-friendly building material production

A kind of construction material and environmental protection technology, applied in the direction of spraying device, spray booth, cleaning method and utensils, etc., can solve the problems affecting the quality of the plate, inconvenient to use, etc., and achieve the effect of improving the quality of painting, convenient use and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

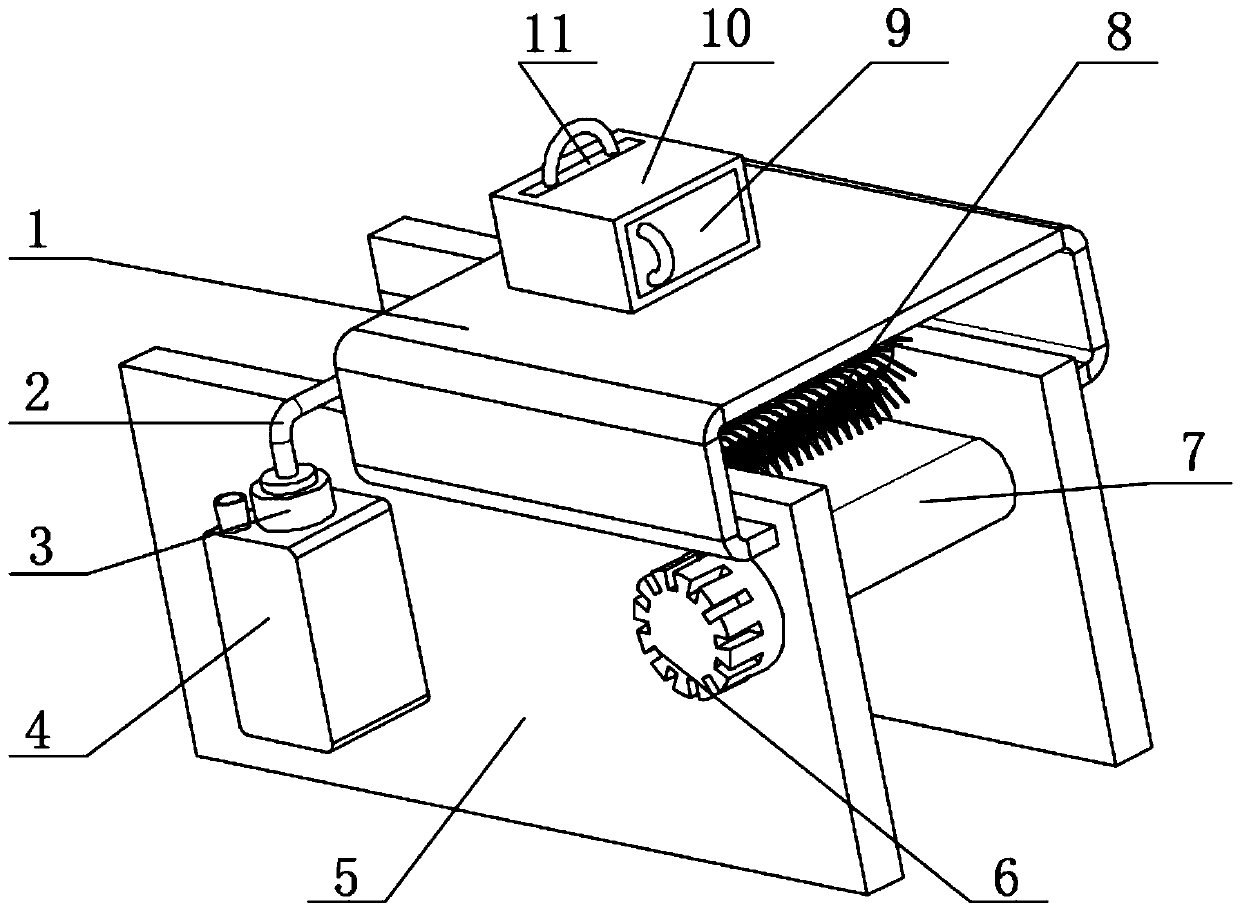

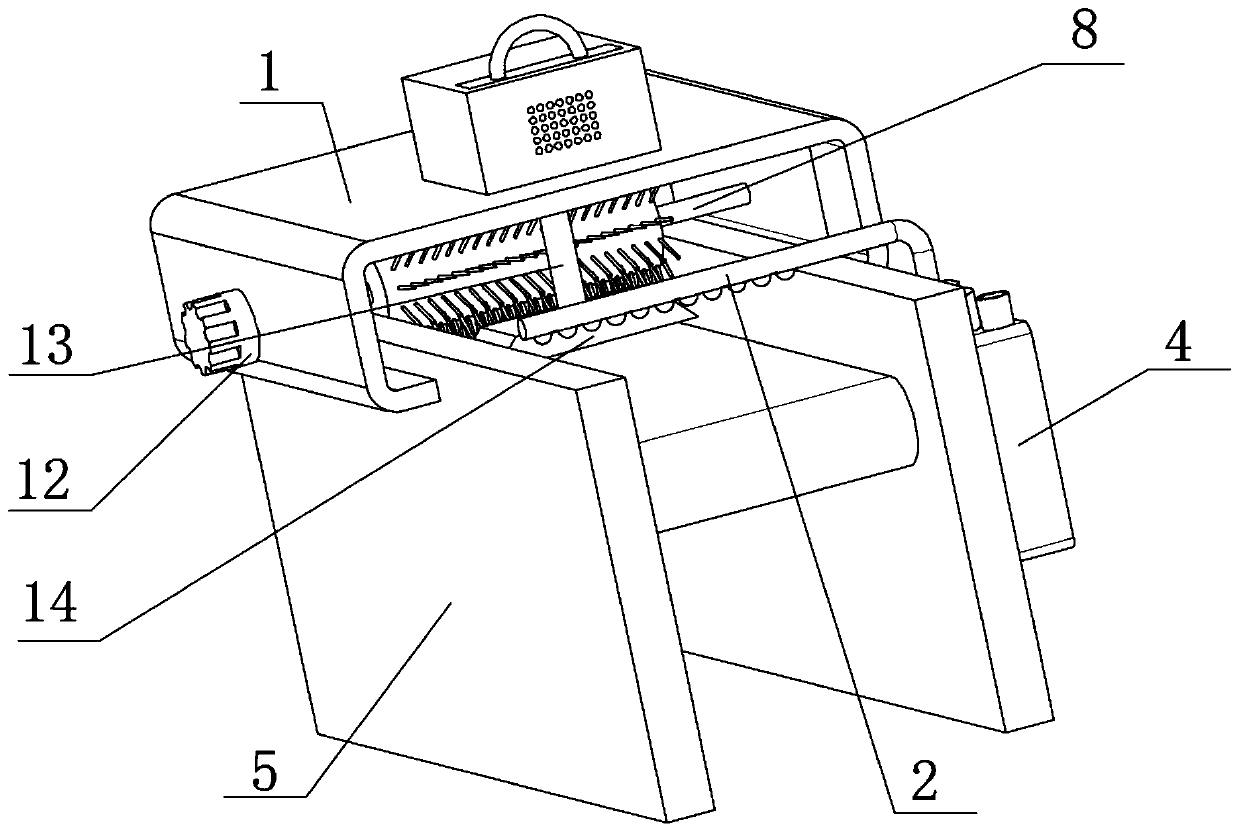

[0023] refer to Figure 1-2 , a painting device for the production of environmentally friendly building materials, including two support plates 5, two rotating shafts are rotatably connected to the outer walls of the opposite ends of the two supporting plates 5, and the same conveyor belt 7 is sleeved on the outer walls of the circumference of the two rotating shafts , the outer walls of one end of the two support plates 5 are far away from each other are equipped with the same connecting plate 1, and the inner walls at both ends of the connecting plate 1 are rotatably connected with the same rotating shaft 8, and the outer wall of the rotating shaft 8 is sleeved with a flexible bristle roller, and the connecting plate 1 A motor 12 is installed on the outer wall of one end, and the output end of the motor 12 is fixedly connected with the outer wall of one end of the rotating shaft 8 through bolts.

[0024] In the present invention, a servo motor 6 is installed on one side of t...

Embodiment 2

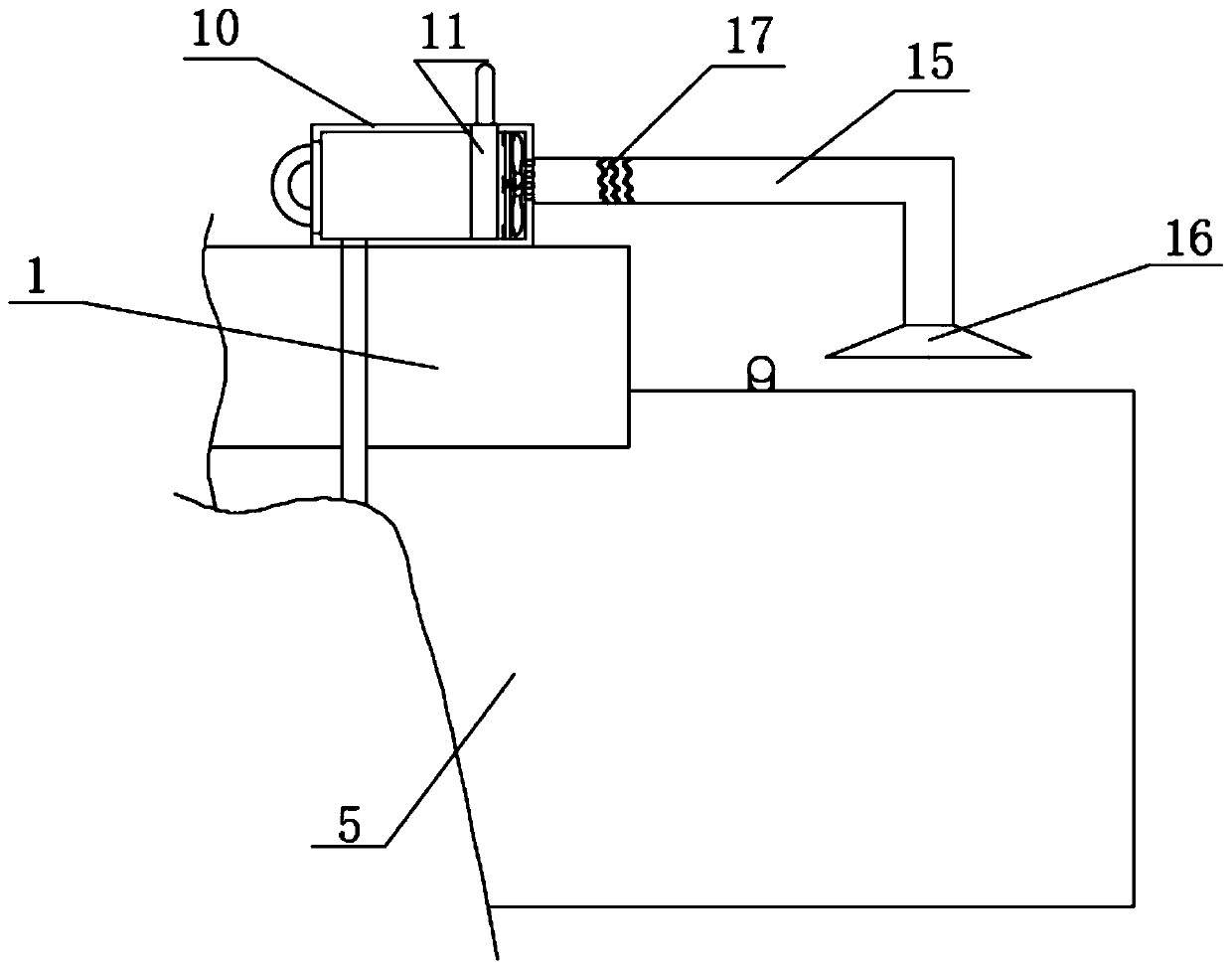

[0027] refer to Figure 1-3 , a painting device for the production of environmentally friendly building materials, which also includes an air duct 15 installed on the outer wall of one side of the storage housing 10, and an air outlet bucket 16 is installed at the other end of the air duct 15, and equidistantly distributed heating elements are installed on the inner wall of the air duct 15. Wire 17, the air vent is located inside the air duct 15.

[0028] Working principle: Compared with Example 1, by setting the air duct 15, the heating wire 17 and the air outlet bucket 16, the board after painting can be dried, and the wind force after dust removal can be used to achieve energy saving Effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com