Multifunctional die box

A mold box, multi-functional technology, applied in the direction of drawing dies, etc., can solve the problems of lubricating powder accumulation in corners, agglomeration, difficult to use effectively, etc., to improve the effect of agitation and the effect of sufficient agitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

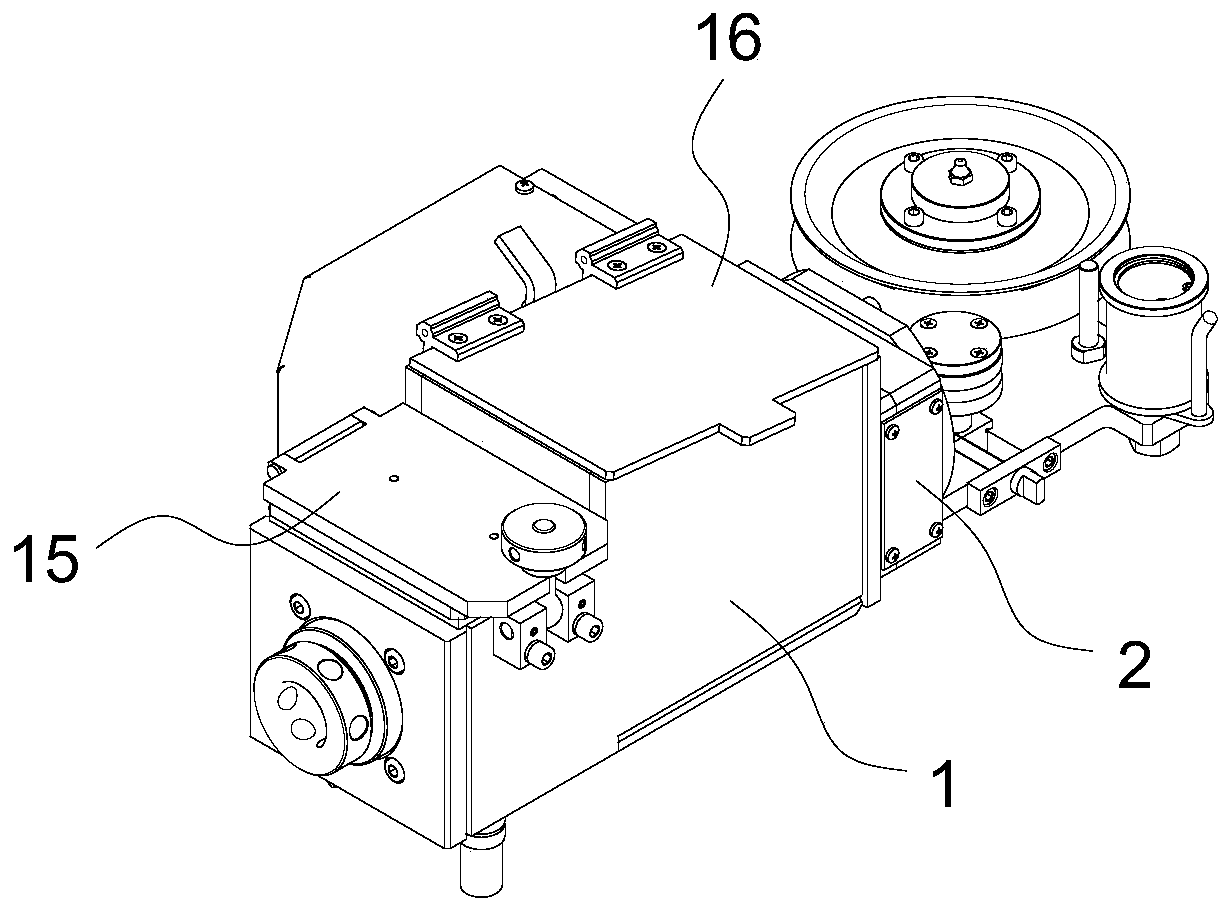

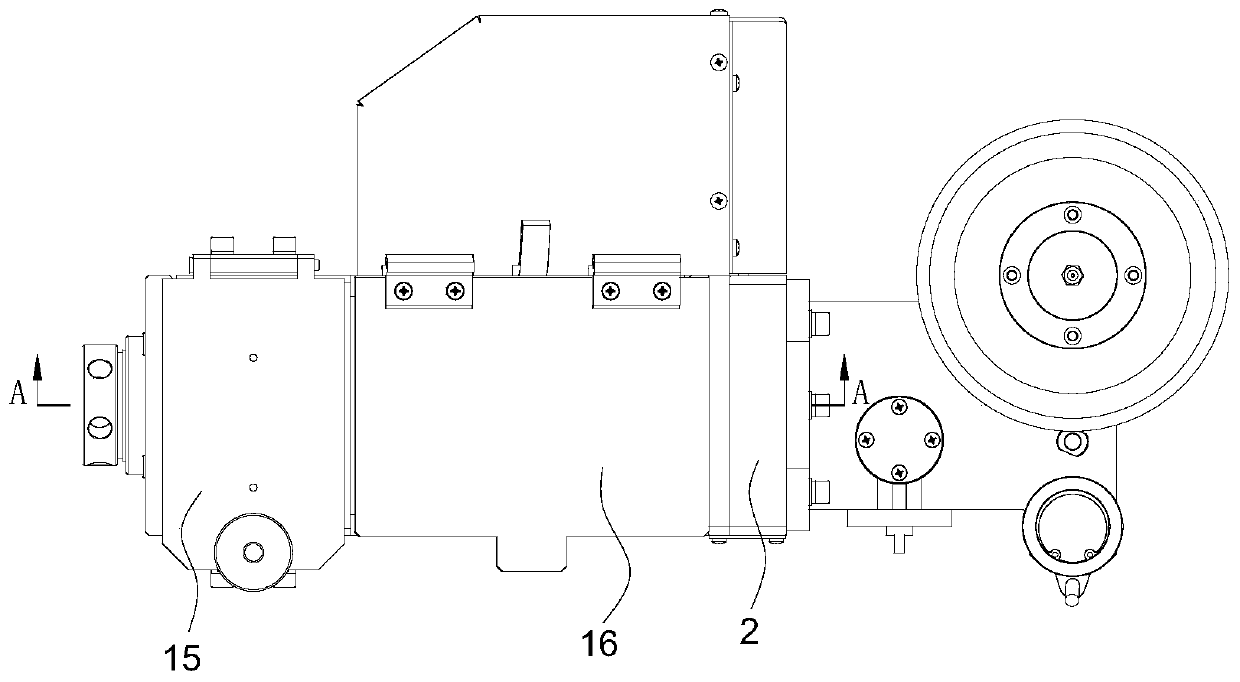

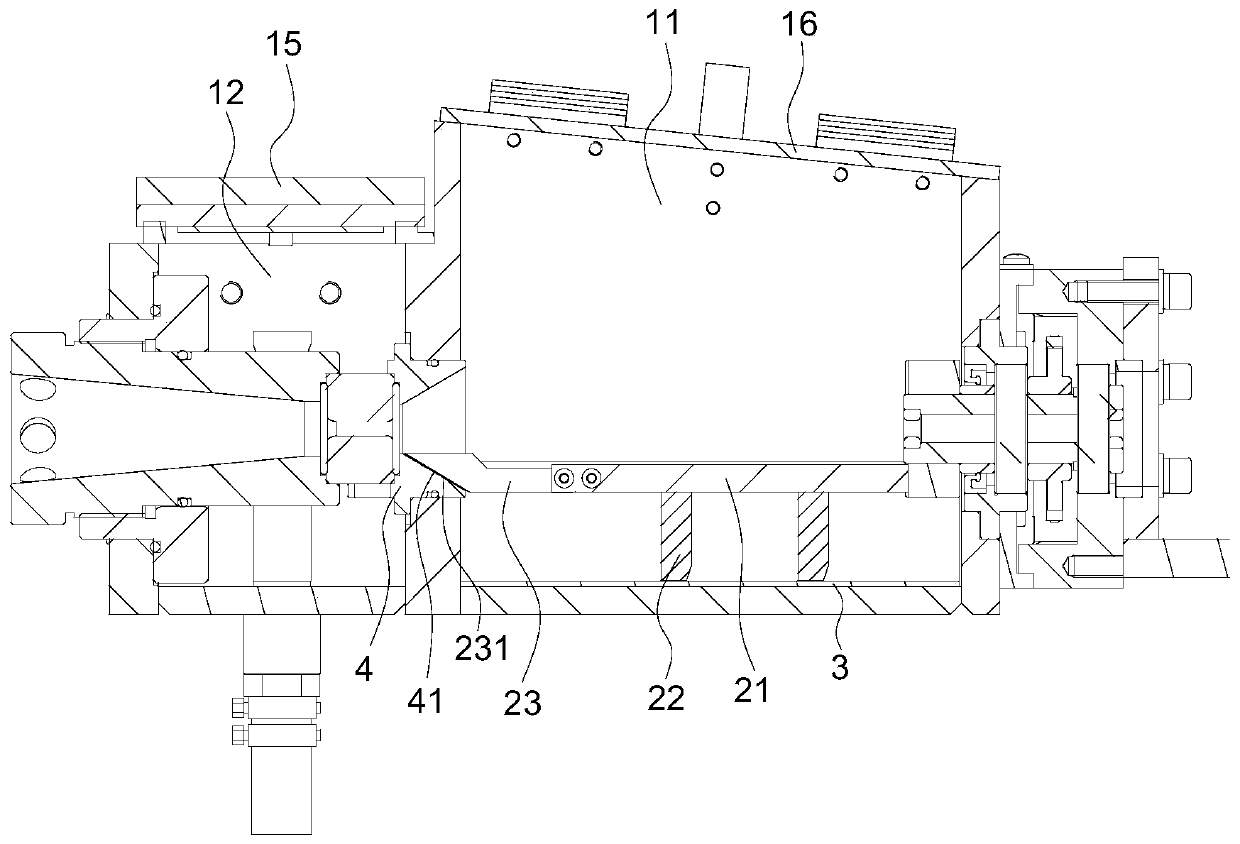

[0041] Such as Figure 1 to Figure 6As shown, a multifunctional mold box includes a box body 1 and an agitating mechanism 2. The box body 1 is provided with a powder chamber 11, and the bottom of the powder chamber 11 is provided with a groove bottom plate 3. The groove bottom plate 3 is a semicircular tube, and the opening of the groove bottom plate 3 Put it upwards to hold the lubricating powder. The box body 1 is provided with a back mold cover 4, and the back mold cover 4 is provided with a taper hole 41 to guide the wire to pass through the mold box during drawing. The stirring mechanism 2 and the box body 1 Fixed connection, stirring mechanism 2 comprises stirring rod 21, and stirring rod 21 rotates around metal wire, and the axis of rotation of stirring rod 21 coincides with the center line of tank bottom plate 3, and stirring rod 21 is provided with several first scrapers 22 at intervals, the first The bottom surface of the scraper 22 is matched with the inner circular...

Embodiment 2

[0047] Such as Figure 7 , Figure 8 As shown, on the basis of the structure of Embodiment 1, the first scraper 22 is a rectangular plate, and the first scraper 22 is provided with a plurality of through grooves 221, and when the lubricant powder is stirred, the lubricant powder can pass through the grooves 221 , change the position, improve the effect of agitation, which is beneficial to evenly suspend the agitating lubricating powder in the powder cavity, and evenly deposit on the metal wire passing by at high speed. The central planes of two adjacent first scrapers 22 intersect to form an angle. When stirring The lubricating powder can be squeezed to both sides to make the agitation more sufficient and further improve the agitation effect. The center plane of the first scraper 22 passes through the centerline of the bottom plate 3 of the groove, and one end of the first scraper 22 is fixed on the stirring rod 21 , the other end of the first scraper 22 is provided with an a...

Embodiment 3

[0049] Such as Figure 9 , Figure 10 As shown, on the basis of the structure of Embodiment 1, the middle part of the upper end of the first scraper 22 is fixed on the stirring rod 21, and intersects with the stirring rod 21 to form an included angle. When stirring, the lubricating powder can be squeezed to both sides, so that Agitation is more sufficient to improve the effect of agitation. The first scraper 22 is provided with a number of through holes 223. When agitating the lubricating powder, the lubricating powder can pass through the holes 223, change the position, and further improve the effect of agitation, which is conducive to agitation and lubrication. The powder is evenly suspended in the powder chamber, and evenly deposited on the high-speed passing metal wire. The first scraper 22 is provided with a curved surface 224. The curved surface 224 is matched with the inner circular surface of the groove bottom plate 3. The axial projection is an arc to ensure that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com