Auxiliary device for laser cutter workbench

A laser cutting machine and auxiliary device technology, applied in auxiliary devices, welding/cutting auxiliary equipment, laser welding equipment, etc., can solve the problems of reduced cutting quality, cutting errors, and easy shaking of materials, so as to increase stability and avoid shaking , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

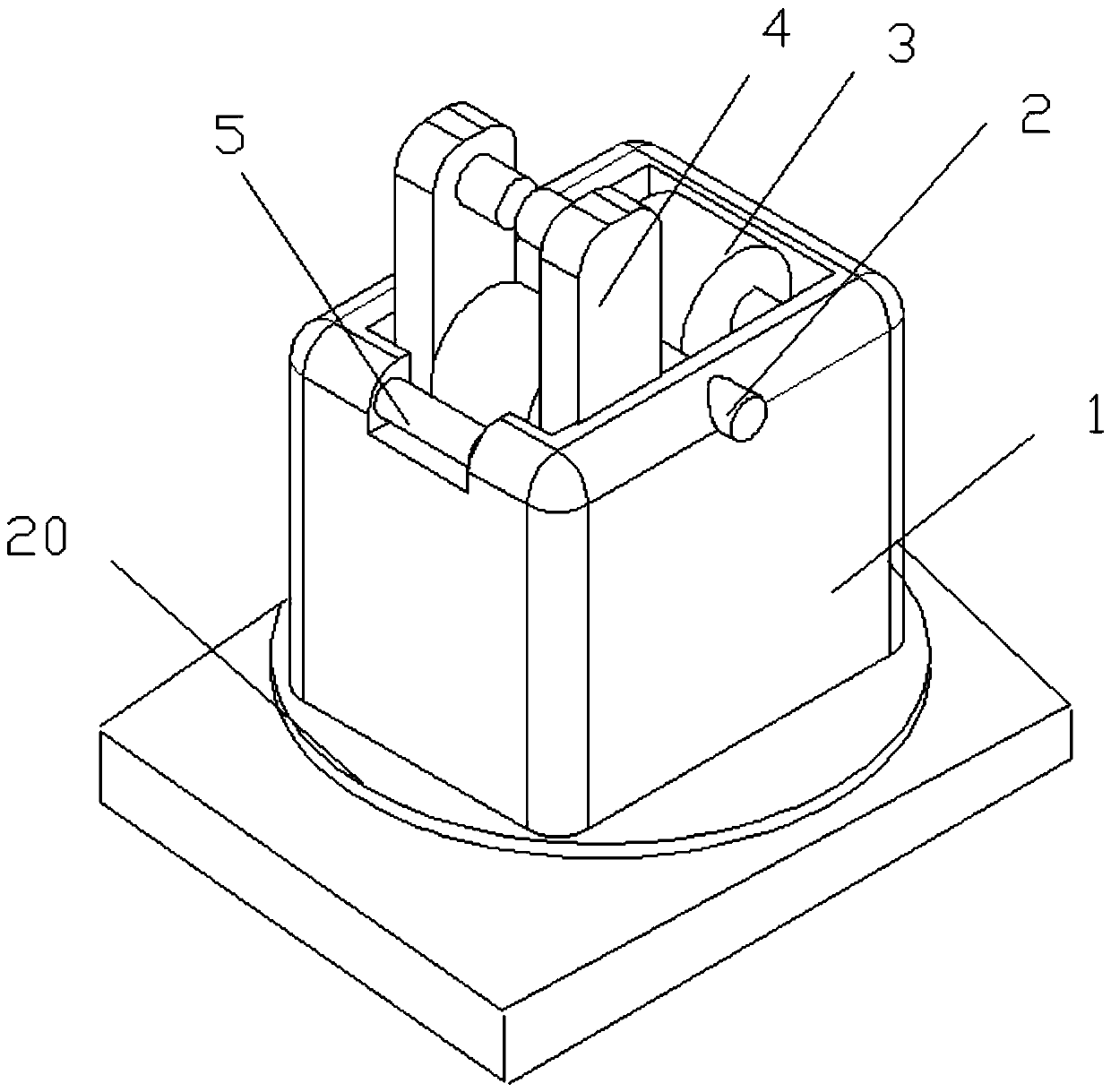

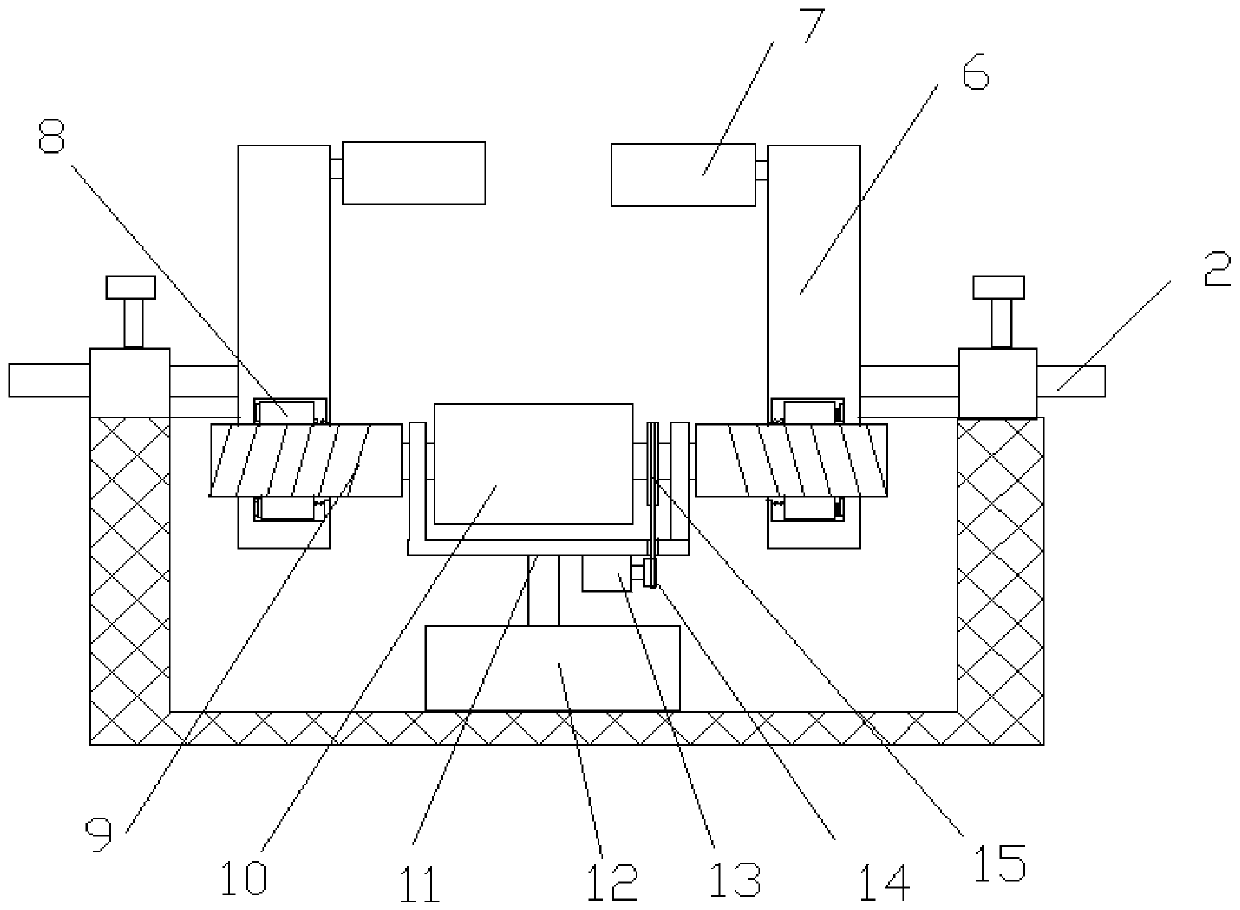

[0025] see Figure 1-4 , an auxiliary device for a laser cutting machine table, including a housing 1 , a first transmission device 4 and a second transmission device 3 . The bottom of the casing 1 is fixedly arranged on the upper surface of the rotating seat 20, and the rotating seat 20 can be rotated, so that the casing 1 can rotate, which facilitates the adjustment of the horizontal cutting angle of the material. The proximal side wall of the casing 1 is rotatably provided with a supporting roller 5, which has a supporting effect on the material, avoids contact between the material and the casing 1, and makes feeding of the material more convenient. The first transmission device 4 includes a first rotating roller 10, a threaded roller 9 and a vertical rod 6, the first rotating roller 10 is rotatably arranged at the inner proximal end of the housing 1, and the inner proximal end of the housing 1 is equipped with a first cylinder 12, The first cylinder 12 is connected with a...

Embodiment 2

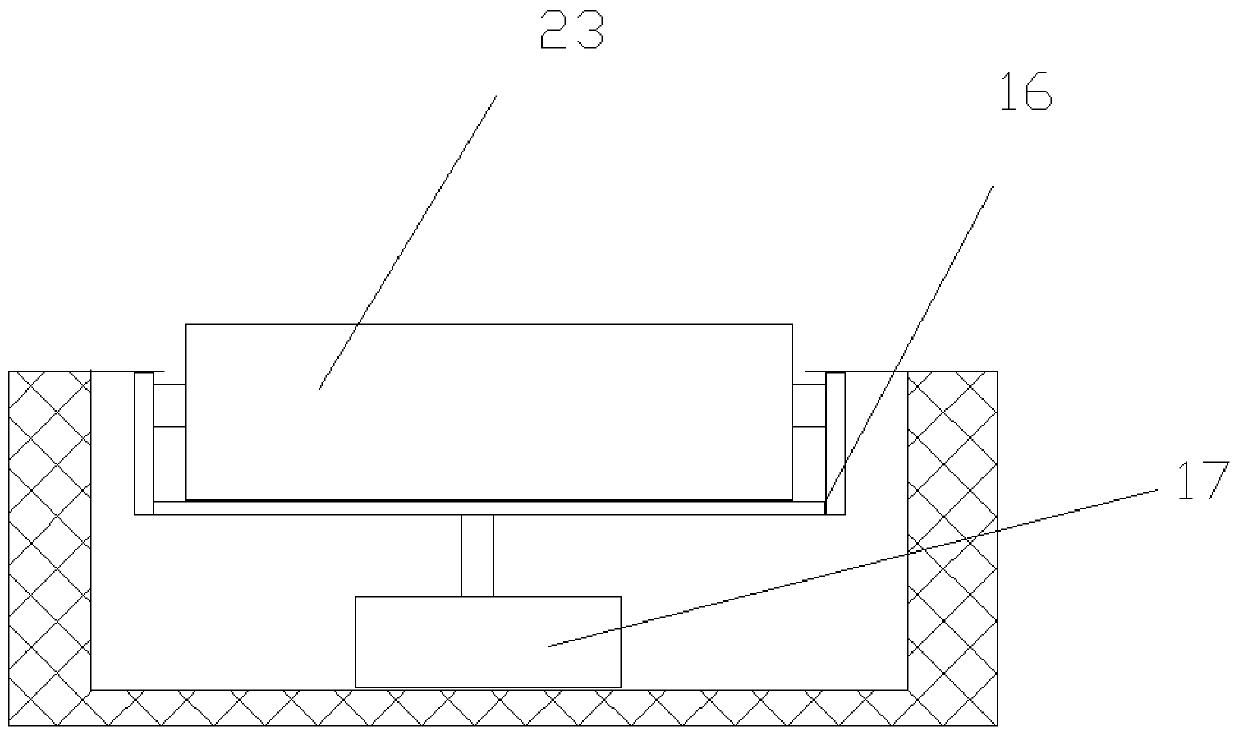

[0030] see Figure 5 , On the basis of Embodiment 1, the outer side of the drive sleeve 8 is fixedly provided with a multi-prism sleeve 22 , and the inner and outer sides of the vertical rod 6 are provided with grooves corresponding to the multi-prism sleeve 22 . Under the action of the spring 18, the transmission sleeve 8 and the rotating sleeve 19 slide outwards, the polygonal column sleeve 22 is stuck inside the groove, and the threaded roller 9 rotates to drive the transmission sleeve 8 and the vertical rod 6 to move. When the inner side of the vertical bar 6 clamps the material and is resisted, the transmission sleeve 8 is stressed and the polygonal column sleeve 22 is disengaged from the groove.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap