A mortar spraying device

A spraying device and mortar technology, applied in construction, building structure and other directions, can solve the problems of mortar splashing and reducing cleaning workload, and achieve the effect of preventing splashing, reducing cleaning workload and increasing stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

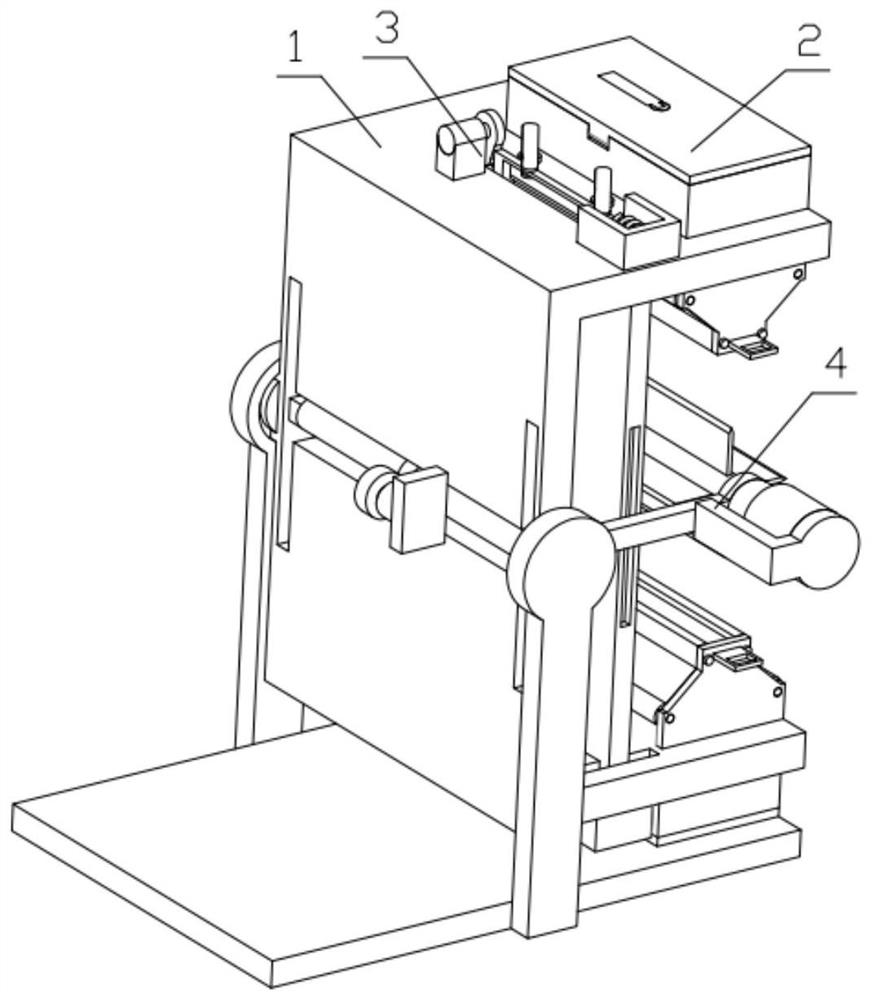

[0044] Combine below Figure 1-22Description of this embodiment, a mortar spraying device, including a device mounting frame 1, a mortar box 2, an impact mechanism 3 and a shooting mechanism 4, the shooting mechanism 4 is installed on the device mounting frame 1, each of the mortar box 2 There are two numbers, respectively installed at the two ends of the device mounting frame 1, and the positions are symmetrical, and there are two impact mechanisms 3, respectively installed at the upper and lower ends of the device mounting frame 1, and the positions are symmetrical.

specific Embodiment approach 2

[0046] Combine below Figure 1-22 Describe this embodiment, this embodiment will further explain the first embodiment, the device mounting frame 1 includes a fixed frame 1-1, an arc-shaped slider 1-2, a supporting side plate 1-3, a base 1-4, and an arc Shaped slider 1-2 is fixedly installed on the fixed frame 1-1, and arc-shaped slider 1-2 is movably installed on the support side plate 1-3. There are two support side plates 1-3, which are respectively fixed on On both sides of the base 1-4, the arc-shaped sliding piece 1-2 and the supporting side plate 1-3 complete the rotation of the device, the structure is simple and reasonable, and the cost of the device is reduced.

specific Embodiment approach 3

[0048] Combine below Figure 1-22 Describe this embodiment, this embodiment will further explain the second embodiment, the mortar box 2 includes a top cover 2-1, a cleaning assembly 2-2, a box body 2-3, a pull-out baffle 2-4, a movable Cover 2-5, the movable cover 2-5 is fixedly connected with the box body 2-3 by screws, the top cover 2-1 is movably installed on the box body 2-3, and the cleaning component 2-2 is movably installed on the top cover 2-1 On the set groove, there are two movable covers 2-5, the movable cover 2-5 is hinged with the box body 2-3, and the positions are symmetrical, and the pull-out baffle 2-4 is movably installed on the box body 2 On the through hole provided on -3, the box body 2-3 is fixedly installed on the fixed frame 1-1; the cleaning assembly 2-2 includes a cleaning frame 2-2-1, a cylinder 2-2-2, and a handle 2-2 -3, the handle 2-2-3 is hinged to the cylinder 2-2-2, the cylinder 2-2-2 is fixedly installed on the cleaning frame 2-2-1, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com