Independent cooling system control system

A control system and heat dissipation system technology, applied in the direction of coolant flow control, fluid pressure actuation system components, fluid pressure actuation devices, etc., can solve the difficulties of control system design and actual vehicle calibration, no solution, and functional differences Major problems, to achieve the effect of facilitating team development, improving modularity, and clear functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] In this embodiment, the present invention is further described.

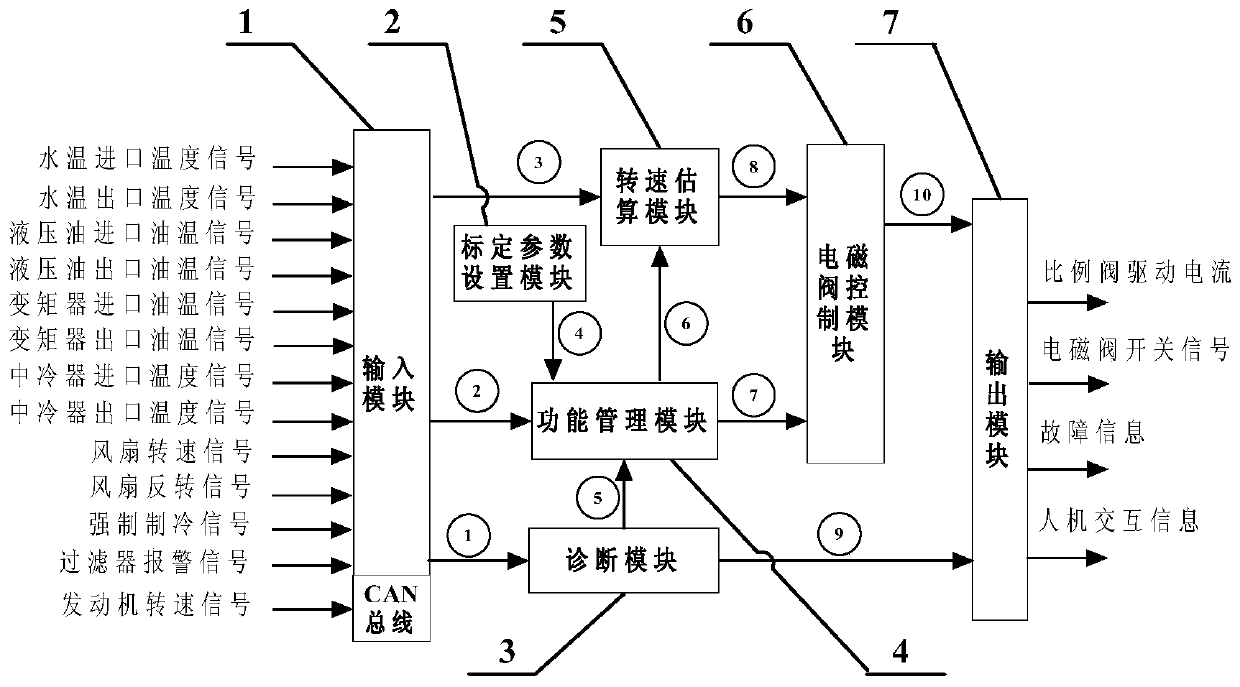

[0083] figure 1 The model architecture of the present invention is described. The input module 1 reads the sensor signal and CAN bus signal from the electronic control unit register, performs noise reduction and filtering processing on the signal, converts the physical quantity according to the engineering unit, and then outputs it to the diagnostic module 3 for signal validity diagnosis; output to the function The management module 4 performs control function management; the output is sent to the rotational speed estimation module 5 to estimate the fan rotational speed.

[0084] The calibration parameter setting module 2 sets the temperature thresholds of water temperature inlet temperature, hydraulic oil inlet oil temperature, torque converter inlet oil temperature, and intercooler outlet temperature; fan speed threshold; fan reverse time and speed threshold; speed sensor every Parameters such as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com