Magnetic fluid sealing rotary joint

A magnetic fluid seal and rotary joint technology, which is applied to engine seals, pipes/pipe joints/fittings, adjustable connections, etc., can solve problems such as large frictional resistance, short-lived seals, friction and wear, and avoid contact friction , Avoid adhesive wear and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

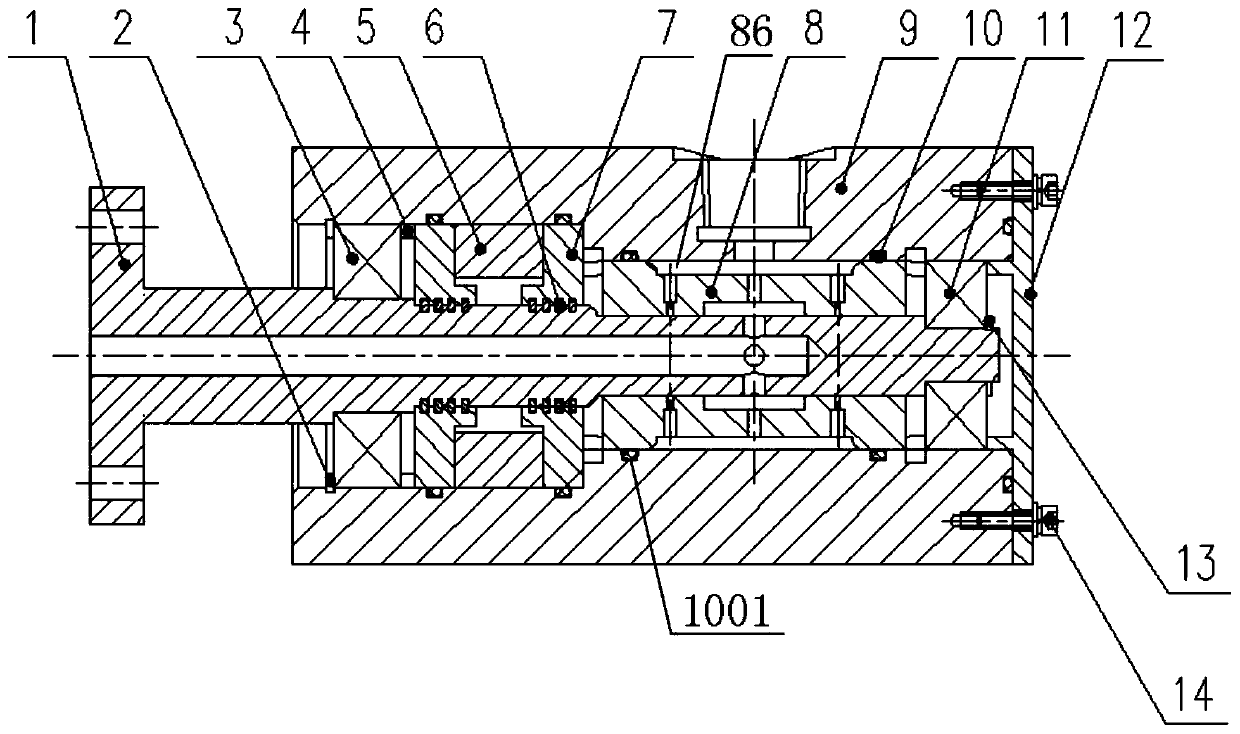

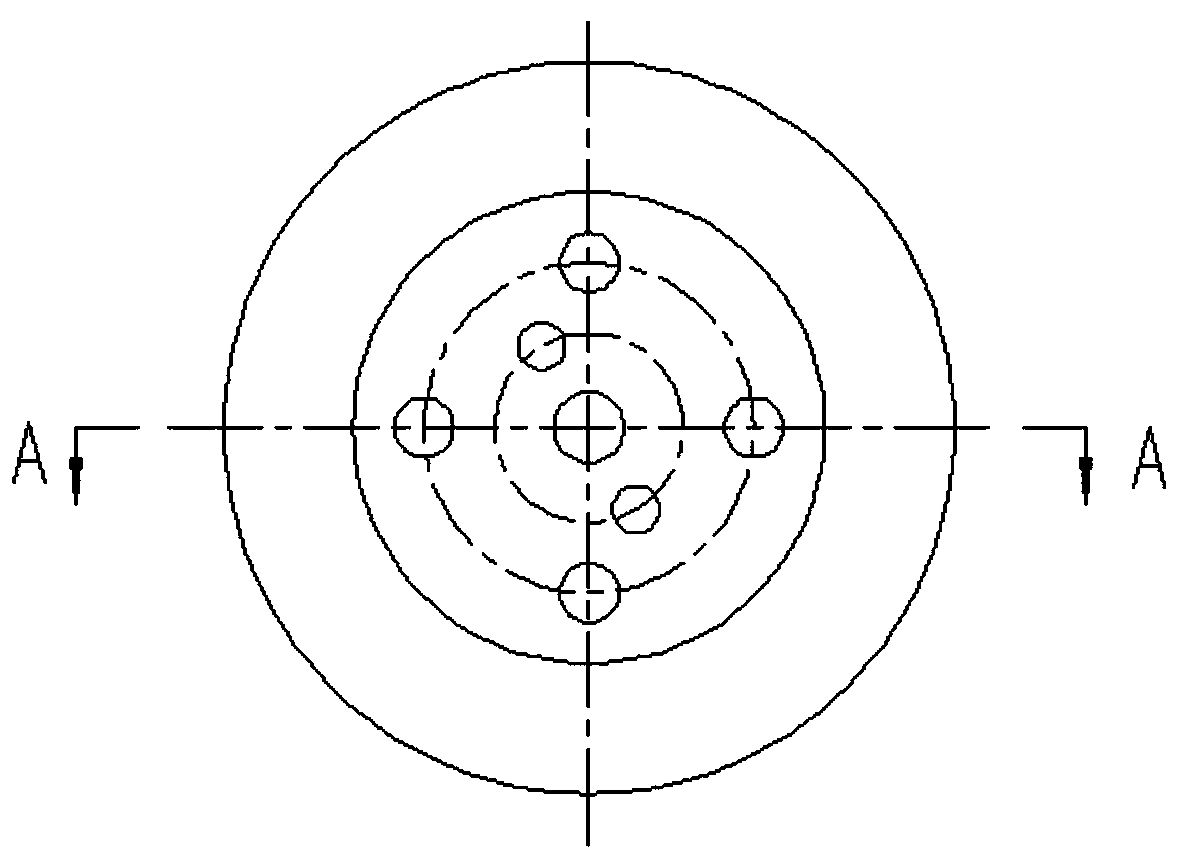

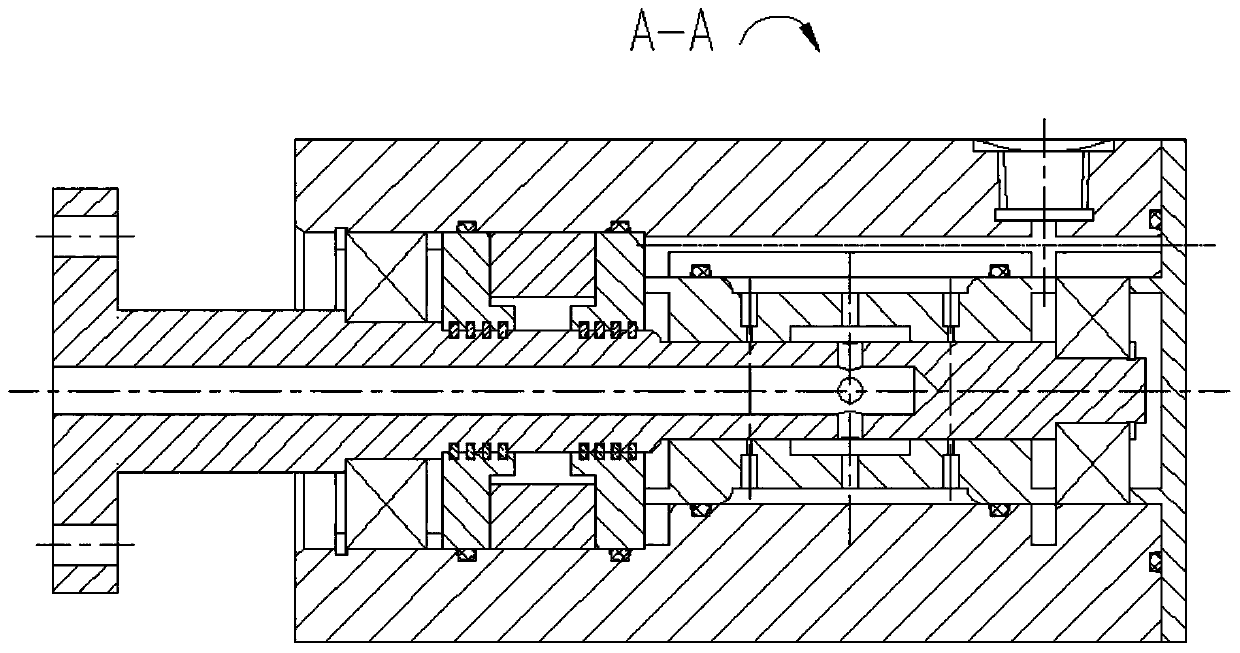

[0032] The present invention will be further described below in conjunction with accompanying drawing:

[0033] like Figure 1-3 shown;

[0034] Ferrofluid sealed rotary unions, including:

[0035] A shaft 1; a first airway is formed in the shaft 1;

[0036] Floating ring 8; the floating ring 8 is formed into a ring; a second air passage is formed in the floating ring 8; at least two rows of throttle holes 81 are arranged on the radial direction of the floating ring 8, and one end of the throttle hole 81 is connected to the floating ring 8 and The gap between the shafts 1 communicates, and the other end of the throttle hole 81 communicates with the second air passage;

[0037] The pole shoe 7; the pole shoe 7 is formed into a ring shape; the floating ring 8 and the pole shoe 7 are both set on the shaft 1, and form a clearance fit with the shaft 1;

[0038] A permanent magnet 5; the permanent magnet 5 is connected to the pole piece 7, the gap between the shaft 1 and the pol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com