Heterostructure simulation method based on ABAQUS

A technology of heterostructures and simulation methods, applied in the direction of design optimization/simulation, etc., can solve the problem of unable to consider special strengthening of heterostructures, unable to consider cross-scale grains, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] An ABAQUS-based heterogeneous structure simulation method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific examples.

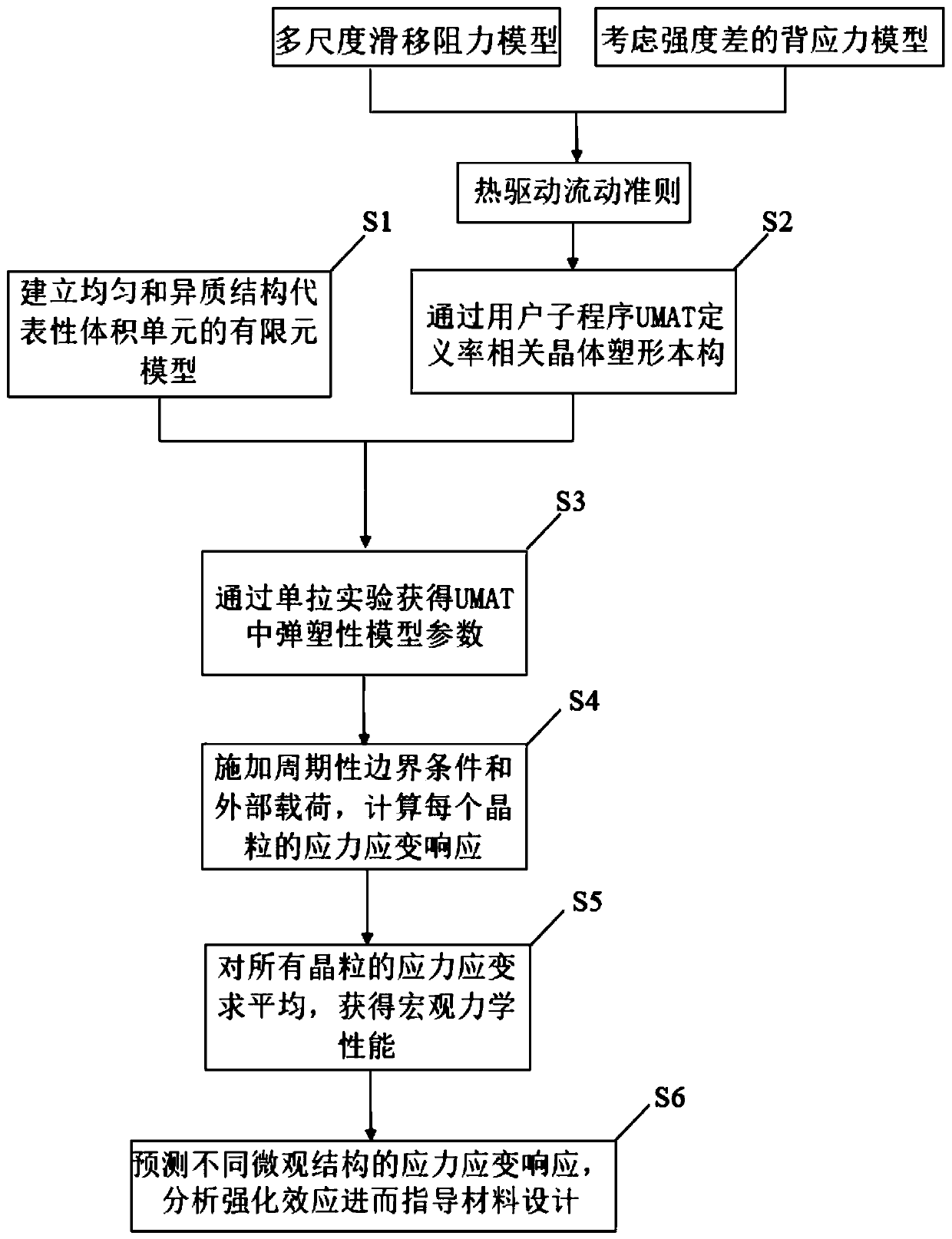

[0066] figure 1 It is a flowchart of an ABAQUS-based heterostructure simulation method according to an embodiment of the present invention. Among them, the heterostructure is a structure designed across the grain size of the scale, including heterogeneous bimodal structure, lamellar structure and gradient structure, etc., and is specifically obtained by annealing after cold rolling to form local grain recrystallization.

[0067] Such as figure 1 As shown, in this embodiment, the simulation method based on ABAQUS and crystal plasticity constitutive design of heterogeneous structure materials includes steps:

[0068] S1: Establish ABAQUS representative unit models of homogeneous and heterogeneous structures;

[0069] Wherein, step S1 specifically includes:

[0070] S11: Estab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com