An array integrated micro LED chip and its manufacturing method

A LED chip and miniature technology, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of high transfer accuracy requirements, low transfer process yield, and low transfer yield, so as to improve integration and utilization, Improve packaging efficiency and yield, and solve the effect of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

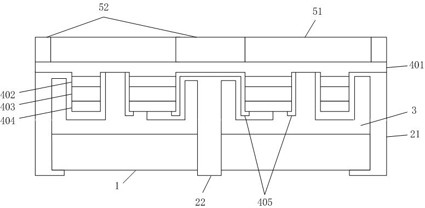

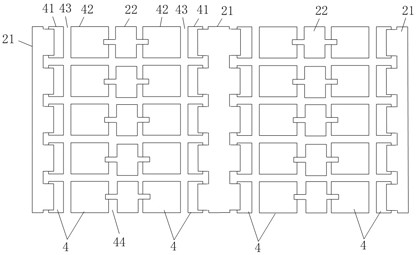

[0044] see figure 1 with figure 2, an array integrated micro LED chip provided by the present invention, comprising a substrate 1, a conductive connection layer, a thermosetting buffer layer 3 and n light emitting structures 4, the n light emitting structures 4 are divided into x rows and y columns, n>3, x>1, y>1; each light emitting structure 4 includes a first light emitting microstructure 41, a second light emitting microstructure 42 and a first isolation groove 43, and the first isolation groove 43 is arranged between the first light emitting microstructure 41 and the first light emitting microstructure 42. Between the second light-emitting microstructures 42; in the same row, a second isolation groove 44 is provided between two adjacent light-emitting structures 4; the conductive connection layer includes a first metal connection layer 21 and a second metal connection layer 22 , the first metal connection layer 21 forms a conductive connection to the first light-emittin...

Embodiment 2

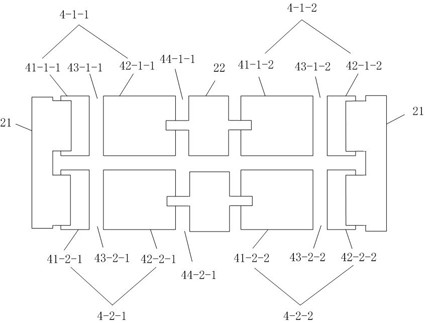

[0070] see image 3 , the LED chip of this embodiment includes 4 light-emitting structures, and the 4 light-emitting structures are divided into 2 rows and 2 columns, wherein the 2 light-emitting structures in the first row are marked as 4-1-1, 4-1-2 in sequence, and the second The two light emitting structures in the row are marked as 4-2-1 and 4-2-2 in turn, and the second isolation groove between the light emitting structures 4-1-1 and 4-1-2 in the first row is marked as 44-1 -1, the second isolation groove located between the light emitting structures 4-2-1 and 4-2-2 in the second row is marked as 44-2-1, and the second isolation grooves in the same column are connected.

[0071] Each light emitting structure includes a first light emitting microstructure, a second light emitting microstructure and a first isolation groove, wherein the light emitting structure 4-1-1 includes a first light emitting microstructure 41-1-1, a second light emitting microstructure 42 -1-1 and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com