Connector with testable plugging distance and plugging distance testing method

A technology of connector plugs and connector sockets, which is used in electrical connection testing, parts of connection devices, connections, etc., can solve the problem of incomplete insertion, large connector locking force, and no plug and socket insertion distance. Detection and other problems to achieve the effect of eliminating the influence and eliminating the in-place insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

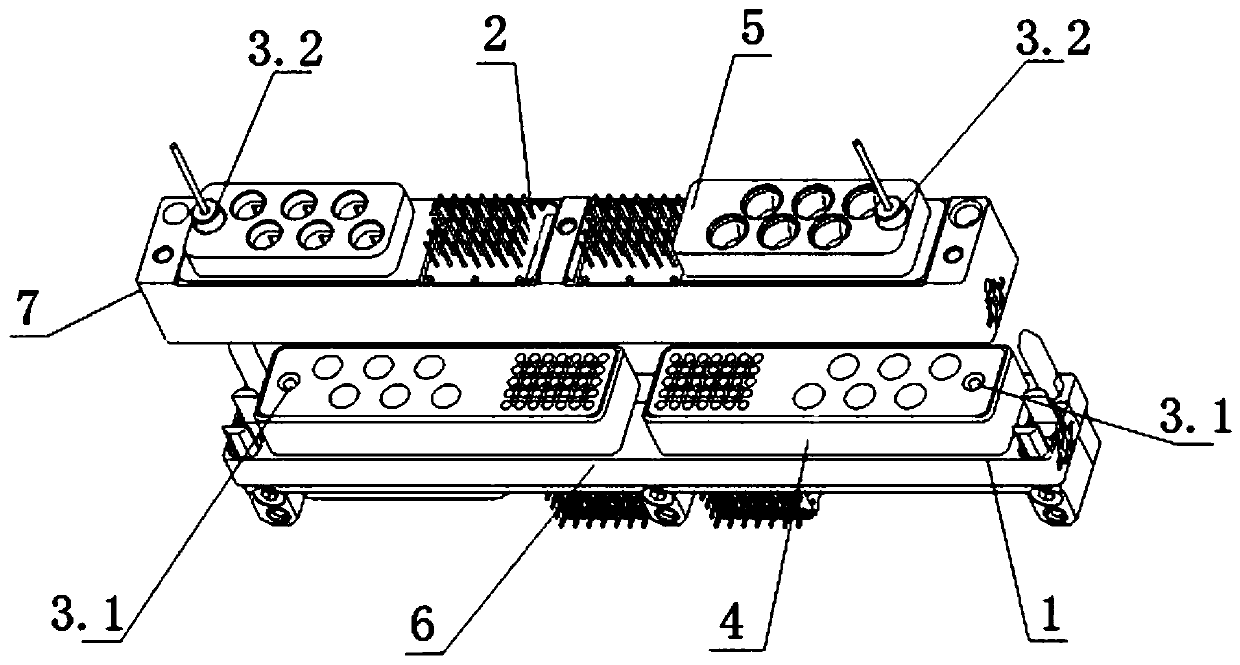

[0056] The test method of the mating distance of the connector comprises the following steps:

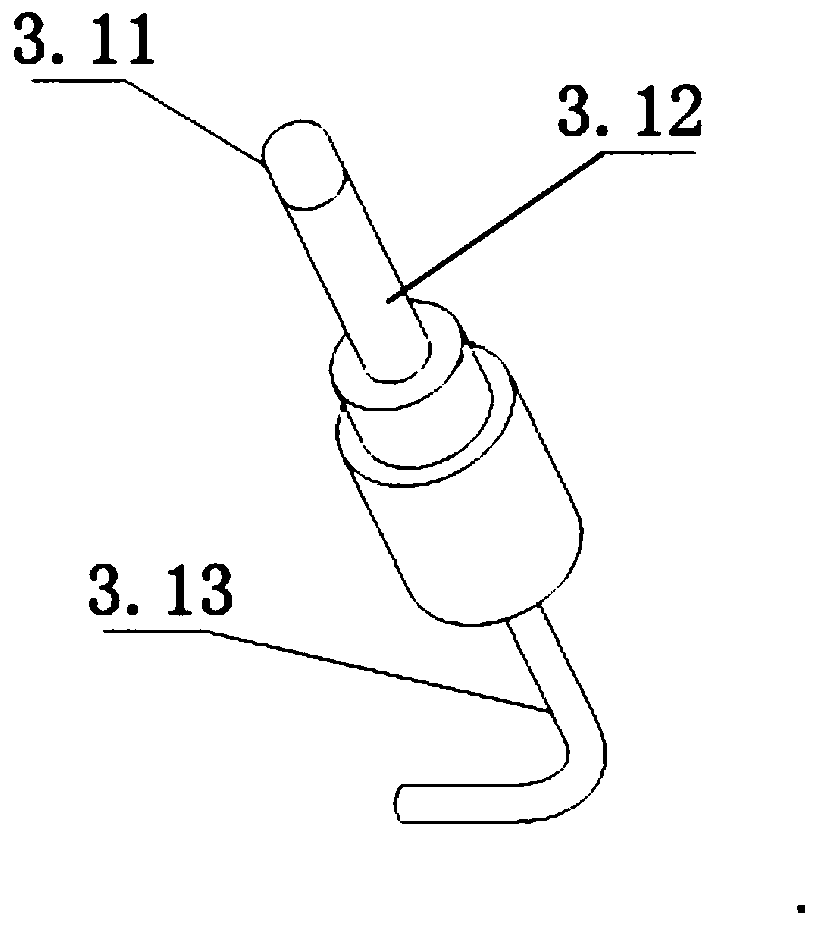

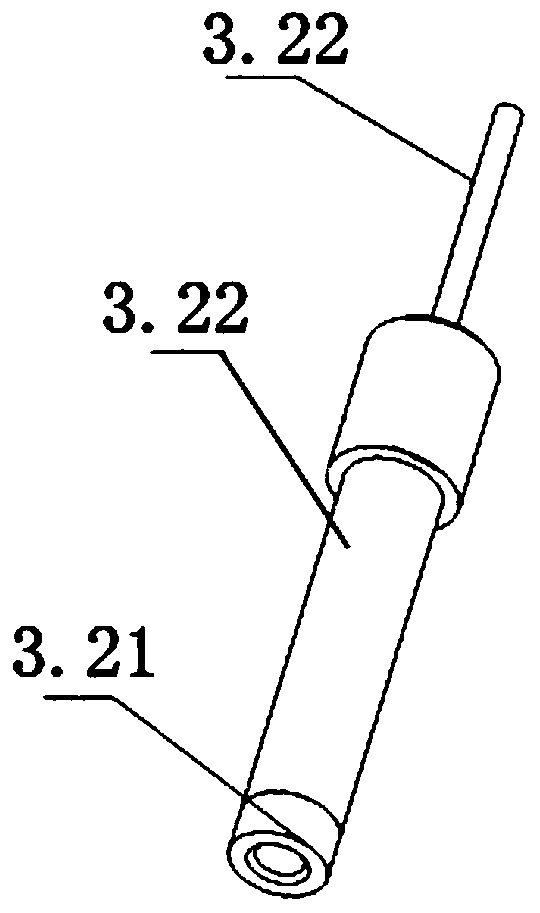

[0057] S1: After the connector plug 1 is mated with the connector socket 2, the same voltage is applied to the two sets of capacitive displacement sensors 3, so that the two sets of capacitive displacement sensors 3 are respectively charged; in this embodiment, the pin terminal 3.1 is grounded, The jack terminal 3.2 has a positive charge.

[0058] S2: Detect the capacitances on the two sets of capacitive displacement sensors 3 through the detection circuit on the device side, and obtain the capacitance values C1=0.91pF and C2=0.93pF;

[0059] S3: According to the calculation formula of pinhole capacitance:

[0060] Calculate the displacement X1=6mm and X2=6mm of the pin terminal 3.1 in the socket terminal 3.2;

[0061] In the formula: the outer diameter of pin terminal 3.1 is d, d=1.9mm

[0062] The outer diameter of jack terminal 3.2 is D; D=2mm

[0063] The dielectric cons...

Embodiment 2

[0069] The test method of the mating distance of the connector comprises the following steps:

[0070] S1: After the connector plug 1 is mated with the connector socket 2, the same voltage is applied to the two sets of capacitive displacement sensors 3, so that the two sets of capacitive displacement sensors 3 are respectively charged; in this embodiment, the jack terminal 3.2 is grounded, Pin terminal 3.1 is positively charged.

[0071] S2: Detect the capacitances on the two groups of capacitive displacement sensors 3 respectively through the detection circuit on the device side, and obtain the capacitance values C1=0.93pF, C2=1.22pF;

[0072] S3: According to the calculation formula of pinhole capacitance:

[0073] Calculate the displacement X1=6mm and X2=8mm of the pin terminal 3.1 in the socket terminal 3.2;

[0074] In the formula: the outer diameter of pin terminal 3.1 is d, d=1.9mm

[0075] The outer diameter of jack terminal 3.2 is D; D=2mm

[0076] The dielect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com